Nano-silicon amorphous carbon composition lithium ion battery cathode material and preparation method therefor

A technology of lithium-ion batteries and negative electrode materials, which is applied in the field of electrochemical power sources, can solve problems such as slow structure destruction, and achieve the effects of long cycle life and large capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

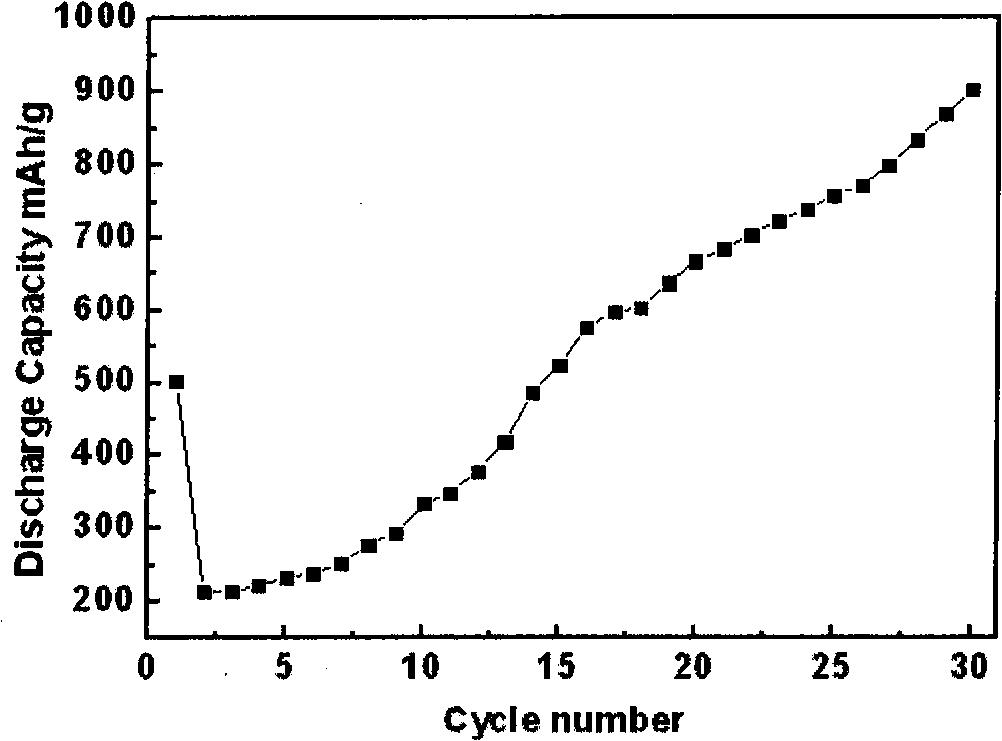

Image

Examples

Embodiment 1

[0028] a) In a water bath at 90°C, 15g of pure polyvinyl alcohol (molecular weight: 80,000) and 135g of deionized water solvent were mixed by strong mechanical stirring for 12 hours until uniform white and transparent;

[0029] b) 1g of nano silicon powder with a particle size of 40nm, 0.5g of surfactant sodium phenylmethylsulfonate and 10g of deionized water were mixed and magnetically stirred for 1 hour, ultrasonicated for 1 hour, and finally stirred for 2 hours;

[0030] c) After mixing the solutions of steps a and b, use strong mechanical stirring for 12 hours, then mix the deionized water solvent, nano silicon powder and polyvinyl alcohol evenly;

[0031] d) Inject the suspension obtained in step c into a syringe, and use a pulse electrostatic generator to generate 25KV high voltage for electrospinning; the tip of the needle is ground flat, with an inner diameter of 1mm, and the flow rate is controlled by a syringe pump at a flow rate of 1ml / h. Collect the grounded alumin...

Embodiment 2

[0035] a) In a water bath at 50°C, 5g of polyacrylonitrile (molecular weight: 90,000) and 45g of solvent dimethylformamide were subjected to strong magnetic stirring for 12 hours until uniform yellow and transparent;

[0036]b) Mix 0.4g of nano silicon powder with a particle size of 40nm, 0.2g of surfactant sodium phenylmethylsulfonate and 10g of dimethylformamide with magnetic stirring for 1 hour, ultrasonication for 1 hour, and finally magnetic stirring for 2 hours ;

[0037] c) After mixing the solutions of steps a and b, use strong magnetic force to stir for 12 hours, and mix the dimethylformamide solvent, nano silicon powder and polyacrylonitrile evenly;

[0038] d) Inject the suspension obtained in step c into a syringe, and use a pulse-type electrostatic generator to generate 20KV high voltage for electrospinning; the tip of the needle is ground flat, with an inner diameter of 1mm, and the flow rate is controlled by a syringe pump at a flow rate of 1ml / h. Collect the g...

Embodiment 3

[0042] a) In a water bath at 40°C, 4g of polymethyl methacrylate (molecular weight: 30,000) and 40g of solvent dimethylformamide were subjected to strong magnetic stirring for 3 hours until uniform and transparent;

[0043] b) 1 g of nano silicon powder with a particle size of 40 nm, 0.5 g of surfactant sodium phenylmethylsulfonate and 8 g of dimethylformamide were mixed magnetically for 1 hour, ultrasonically for 1 hour, and finally magnetically stirred for 2 h;

[0044] d) After mixing the solutions of steps a and b, use strong magnetic force to stir for 12 hours, and mix the dimethylformamide solvent, nano silicon powder and polymethyl methacrylate evenly;

[0045] d) Inject the suspension obtained in step c into a syringe, and use a pulse-type electrostatic generator to generate 18KV high voltage for electrospinning; the tip of the needle is ground flat, with an inner diameter of 1mm, and the flow rate is controlled by a syringe pump at a flow rate of 1ml / h. Collect the gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com