All-optical switch and design method thereof

An all-optical switching and design method technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of less obvious effect, high pump light intensity, singleness, etc., and achieve lower threshold intensity, high switching efficiency, easy to use. effect achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

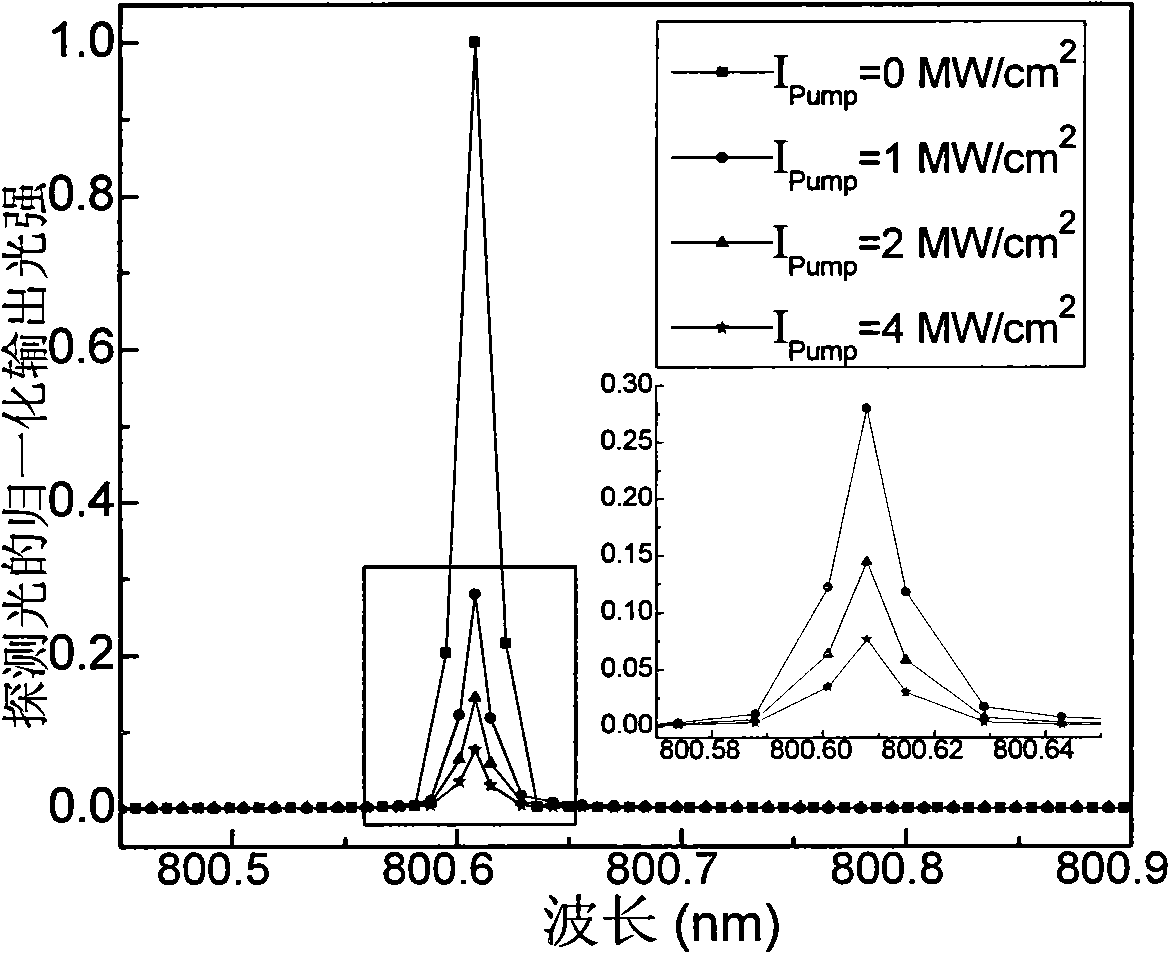

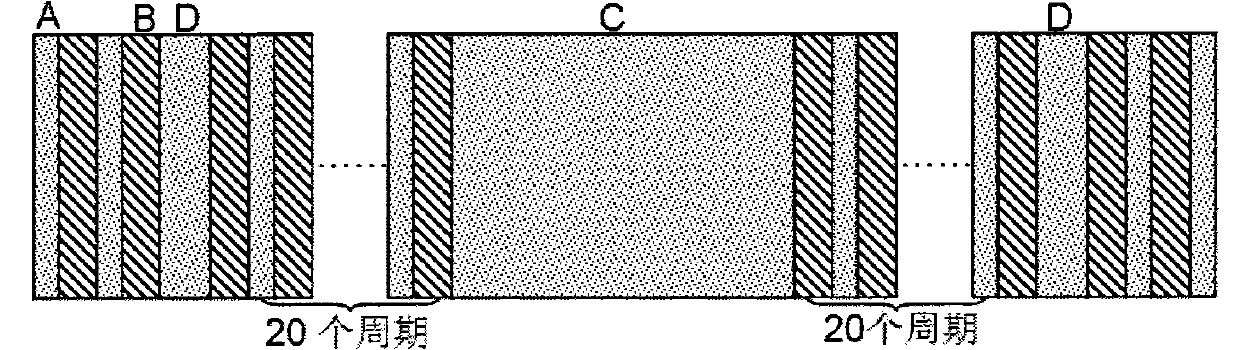

[0029] figure 1 Shown is the one-dimensional multilayer film structure containing three defect layers designed by the present invention, and its design process is specifically as follows:

[0030] Step 101: Incorporate a central defect layer C located in the middle of the multilayer film structure into the multilayer film structure in which the first medium layer A with high refractive index and the second medium layer B with low refractive index are alternately stacked, and then in the multilayer film structure Two side defect layers D are symmetrically doped into two ends far away from the center defect layer C; two adjacent first dielectric layers A and second dielectric layers B form a periodic dielectric film, and the side defect layer D and the center The defect layer C is generally separated by N periods of dielectric film to avoid mutual coupling between the defect layer D and the defect layer C, where N is greater than or equal to 6. The optical thickness of the cent...

Embodiment 2

[0036] figure 2 Shown is the one-dimensional multilayer film structure containing four defect layers designed by the present invention, and its design process is specifically as follows:

[0037] Step 201: symmetrically doping two symmetrical defect layers C located in the middle of the multilayer film structure into the multilayer film structure in which the first medium layer A with high refractive index and the second medium layer B with low refractive index are alternately stacked, and then In the film structure, two side defect layers D are symmetrically doped at both ends away from the adjacent symmetrical defect layer C; the adjacent first dielectric layer A and the second dielectric layer B form a periodic dielectric film, and the side The defect layer D is far away from the adjacent symmetrical defect layer C, and the side defect layer D and the symmetrical defect layer C are generally separated by N periods of dielectric film to avoid mutual coupling between the def...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com