Flocking substrate artificial leather and processing method thereof

A processing method and technology of artificial leather, applied in chemical instruments and methods, textiles and papermaking, layered products, etc., can solve the problems of secondary flocking, easy to fall off, large loss, etc., and achieve good touch, not easy to fall off, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Formula: 100 parts of polyvinyl chloride resin, 45 parts of dioctyl phthalate, 2 parts of barium zinc stabilizer, 5 parts of foaming agent, 6 parts of titanate coupling agent.

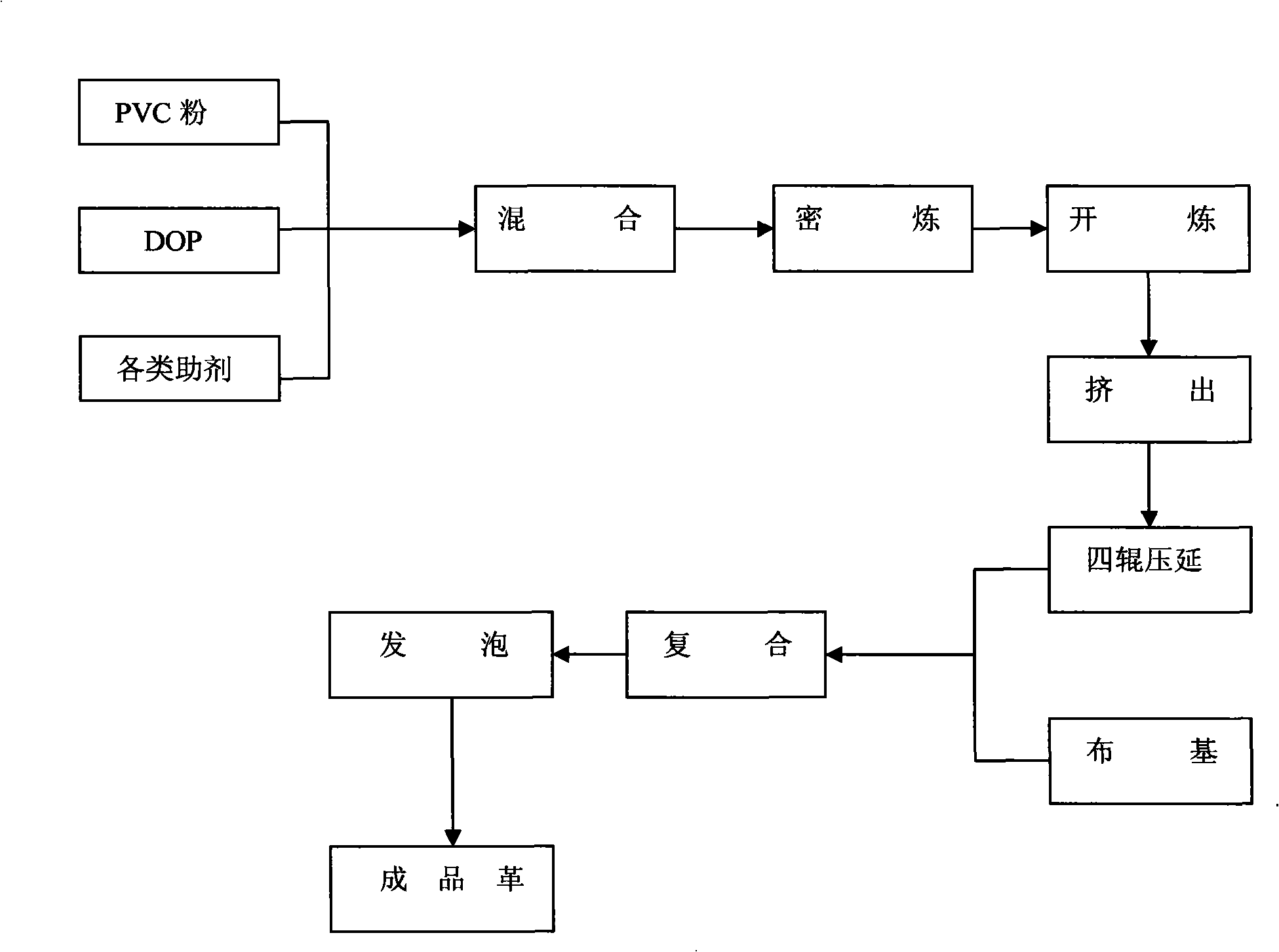

[0031] Processing technology:

[0032] Mixing: Feed according to the requirements of the formula sheet, and use a 55KW mixer to mix at high speed for 4-5 minutes to make the mixture evenly stirred.

[0033] Banburying: put the mixed material into a 10,000-horsepower machine for banburying, and pay attention to the change of current during the banburying process. When the current reaches about 100A, add foaming agent and banbury for 30 seconds.

[0034] Milling: The temperature of the mill must be controlled at about 170°C to ensure that the material is fully plasticized.

[0035] Extrusion: The temperature of the extruder is controlled at about 135°C, pay attention to feeding evenly and avoid stacking.

[0036] Four-roll calendering: To control the temperature of the four rolls, the first roll...

Embodiment 2

[0039] Formula: 100 parts of polyvinyl chloride resin, 40 parts of dioctyl phthalate, 3 parts of barium zinc stabilizer, 4 parts of foaming agent, and 8 parts of titanate coupling agent.

[0040] Processing technology is with embodiment 1.

Embodiment 3

[0042] Formula: 100 parts of polyvinyl chloride resin, 50 parts of dioctyl phthalate, 2 parts of barium zinc stabilizer, 6 parts of foaming agent, and 5 parts of titanate coupling agent.

[0043] Processing technology is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com