Non-woven fabric made by compounding nylon or dacron carding net with spunbond and production method thereof

A technology of spunbond nonwovens and carded webs, applied in nonwovens, textiles and papermaking, etc., can solve the problems of wear resistance, fatigue resistance and corrosion resistance, poor dust absorption performance, low strength, easy deformation, etc. Good dust removal effect, high strength, and the effect of strength is not easy to deform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

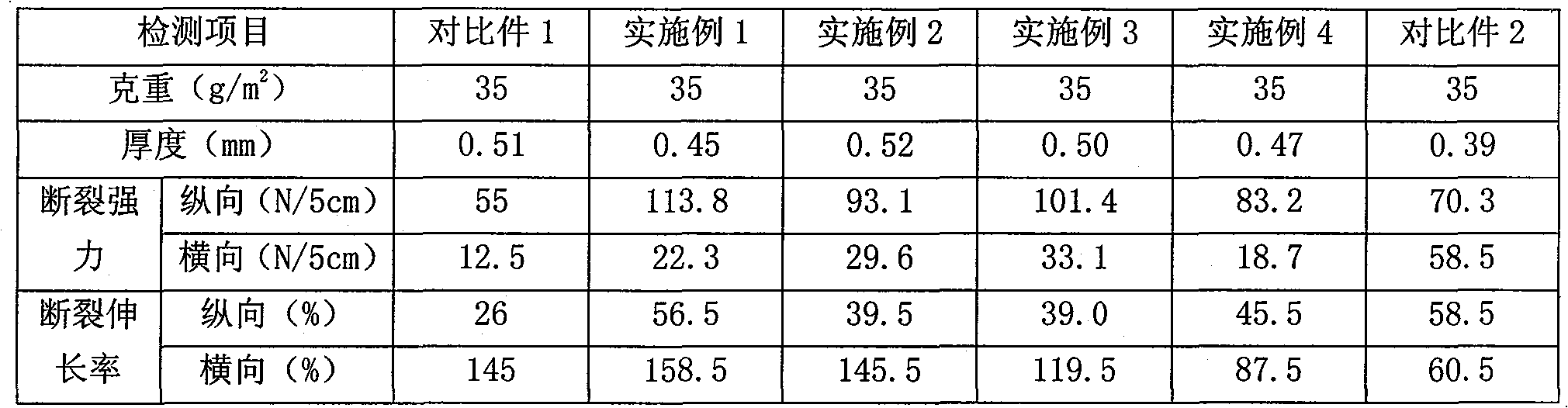

[0015] The upper layer of the present invention is nylon or polyester carded into a web, and the lower layer is nylon or polyester spunbonded nonwoven fabric, which is entangled online or offline by spunlace, and can be formed into four types of products as shown in Table 1. .

[0016]

Example 1

Example 2

Example 3

Example 4

upper layer

Carded Nylon

Carded polyester

Carded polyester

Carded Nylon

lower level

Nylon spunbond nonwovens

Nylon spunbond nonwovens

Polyester spunbond nonwovens

Polyester spunbond nonwovens

[0017] The production method of embodiment 1~embodiment 4 is:

[0018] a. Nylon fiber is opened and cleaned or polyester fiber is processed with an open and clean cotton processor, wherein the cleaning and cleaning of polyester fiber is handled according to the prior art, and nylon fiber is compared with viscose and polyester fiber, and the friction between its fibers Larger, so the openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com