Superficial treatment method of printed wiring board

A printed circuit board and surface treatment technology, which is applied in the direction of liquid chemical plating, metal material coating process, coating, etc., to achieve the effect of preventing oxidation and ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0046] Process parameters:

[0047]

[0048]

[0049] Main steps Material name and content:

[0050] product name

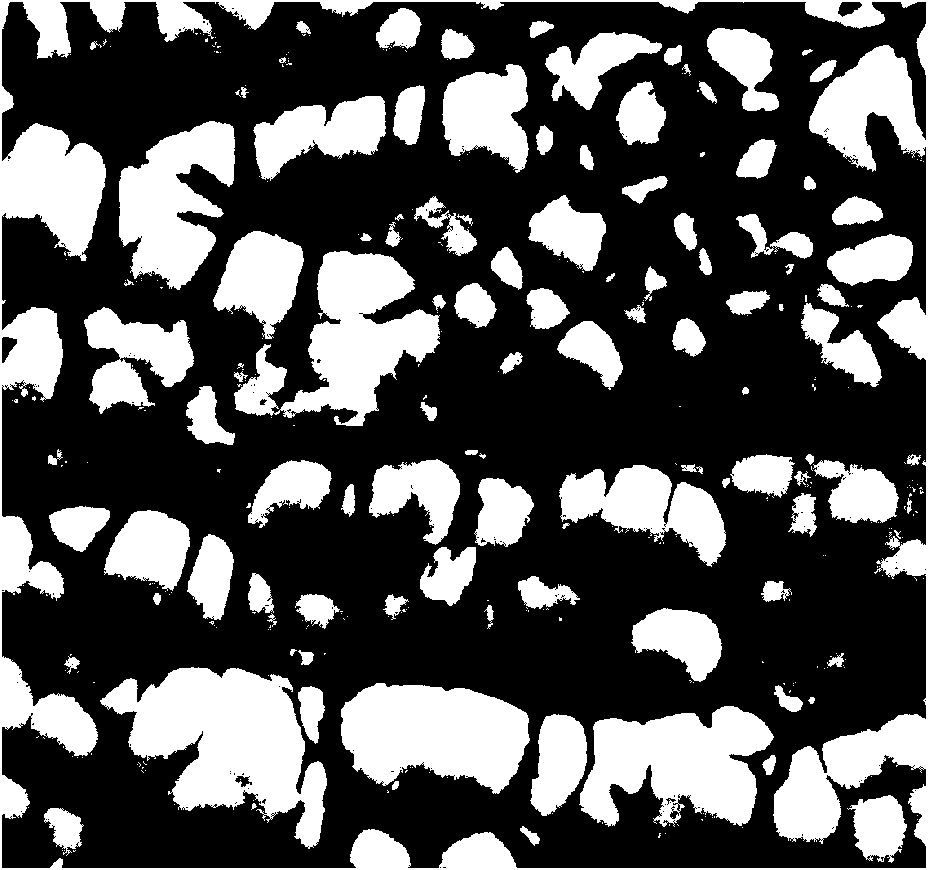

[0051] According to the above process, the appearance of the plated product is uniform, and the bonding strength between the metal layers meets the standard requirements. The thickness of nickel is 4.1um, the thickness of palladium is 0.092um, and the thickness of gold is 0.087um. It is used for SMT (surface mount technology) and Bonding performance test is good. After the gold is withdrawn from the finished product, observe the corrosion condition of the nickel surface, see image 3 , Figure 4 , The results show that there is no black disk phenomenon of nickel corrosion on the surface!

example 2

[0053] Process parameters:

[0054] steps

[0055] Main steps Material name and content:

[0056] product name

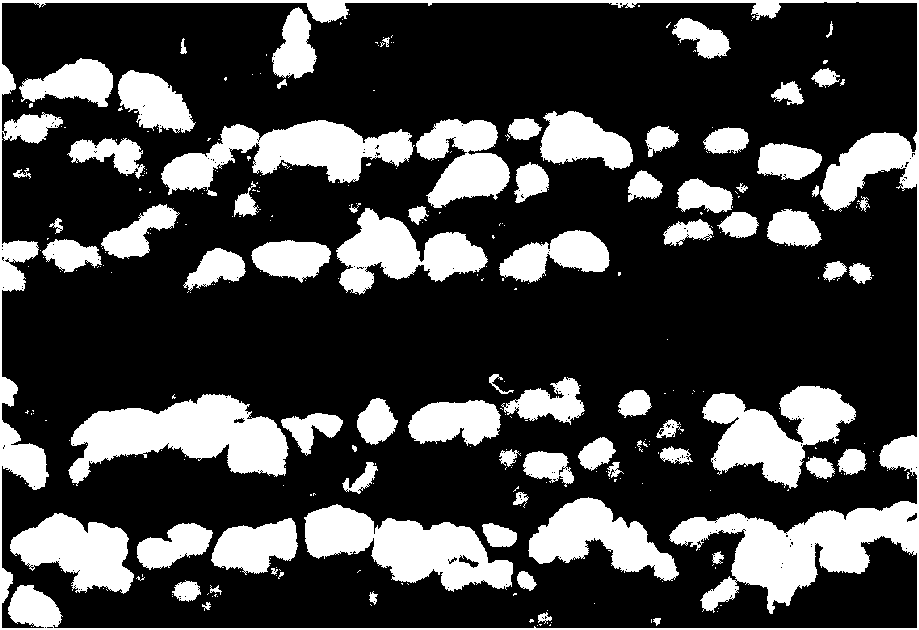

[0057] According to the above process, the appearance of the plated product is uniform, and the bonding strength between the metal layers meets the standard requirements. The thickness of nickel is 4.8um, the thickness of palladium is 0.086um, and the thickness of gold is 0.093um. It is made of SMT (surface mount technology) and Bonding performance test is good. After the gold is withdrawn from the finished product, observe the corrosion condition of the nickel surface, see Figure 5 , Image 6 , The results show that there is no black disk phenomenon of nickel corrosion on the surface!

example 3

[0059] Process parameters:

[0060]

[0061]

[0062] Main steps Material name and content:

[0063]

[0064]

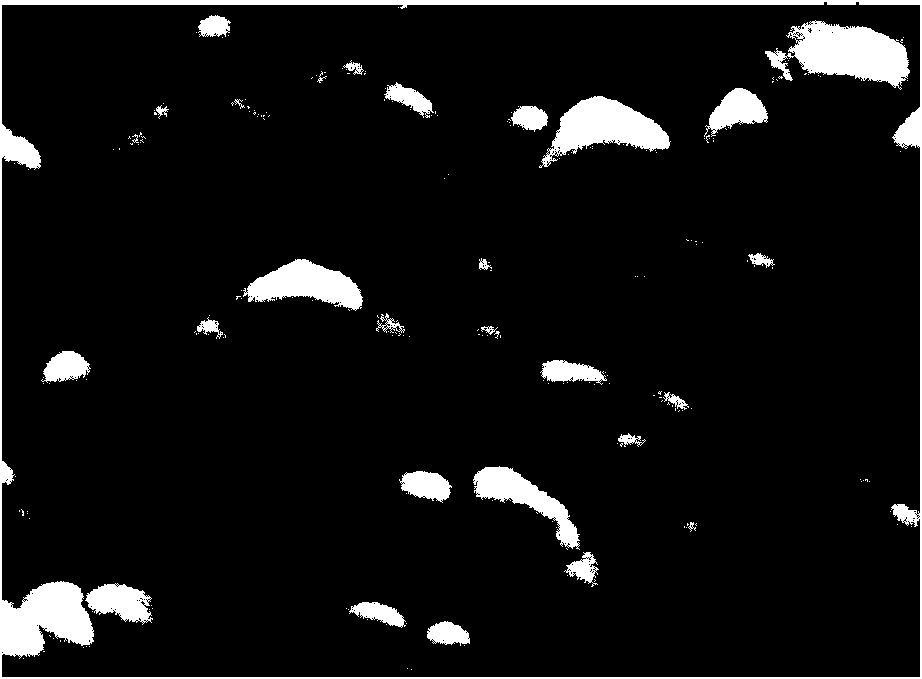

[0065] According to the above process, the appearance of the plated product is uniform, and the bonding strength between the metal layers meets the standard requirements. The thickness of nickel is 4.2um, the thickness of palladium is 0.090um, and the thickness of gold is 0.079um. It is used for SMT (surface mount technology) and Bonding performance test is good. After the gold is withdrawn from the finished product, observe the corrosion condition of the nickel surface, see Figure 7 , Figure 8 , The results show that there is no black disk phenomenon of nickel corrosion on the surface!

[0066] Process characteristics of the present invention: 1. The acidic cleaner is aimed at thin lines, small aperture high-precision circuit boards, has good cleaning power, will not attack the solder resist ink of the circuit board, can strongly remove the oxidatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com