Varnish for partial discharge resistant enameled wire and partial discharge resistant enameled wire

A partial discharge, enameled wire technology, applied in coatings, circuits, electrical components, etc., can solve problems such as insulation damage, and achieve the effects of excellent tensile resistance, improved partial discharge resistance, excellent uniform dispersion and transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

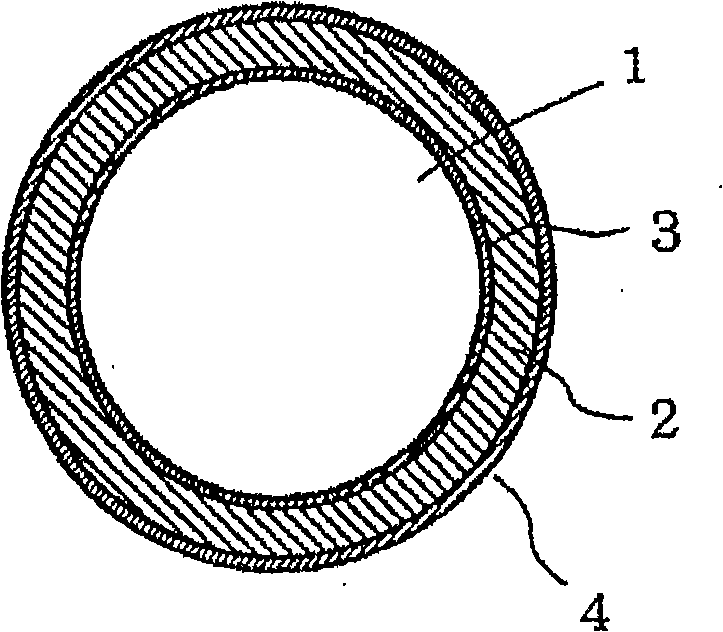

[0055] To trans-2 (hydroxyethyl isocyanurate) modified polyester-imide enameled wire coatings, disperse hollow organosilica sol (benzyl alcohol / naphtha mixed dispersion medium, average silica The particle size is 23nm and the hollow volume ratio is 30%), so that the silica component is 20 parts by weight (parts by mass) relative to 100 parts by weight (parts by mass) of the resin component, thereby obtaining a partial discharge-resistant polyester-imide enameled wire Use paint.

Embodiment 2

[0057] To trans-2 (hydroxyethyl isocyanurate) modified polyester-imide enameled wire coatings, disperse hollow organosilica sol (benzyl alcohol / naphtha mixed dispersion medium, average silica The particle size is 45 nm and the hollow volume ratio is 35%), so that the silica component is 50 parts by weight relative to 100 parts by weight of the resin component, thereby obtaining a partial discharge resistant polyester-imide enameled wire coating.

Embodiment 3

[0059] In the coating for polyamide-imide enameled wire, the hollow organosilica sol (γ-butyrolactone dispersion medium, the average particle size of silica is 23nm, the hollow volume ratio is 30%) is dispersed so that the silica component is relatively 100 parts by weight of the resin component is 20 parts by weight to obtain a polyamide-imide enamelled wire coating that is resistant to partial discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com