Method for manufacturing flexure cylindrical mirror condenser

A manufacturing method and mirror technology, which are applied in the field of solar energy utilization, can solve the problems of high precision requirements, complex processes, and high manufacturing costs, and achieve the effects of simplifying the mirror-making process, increasing the types, and reducing the manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and preferred embodiments.

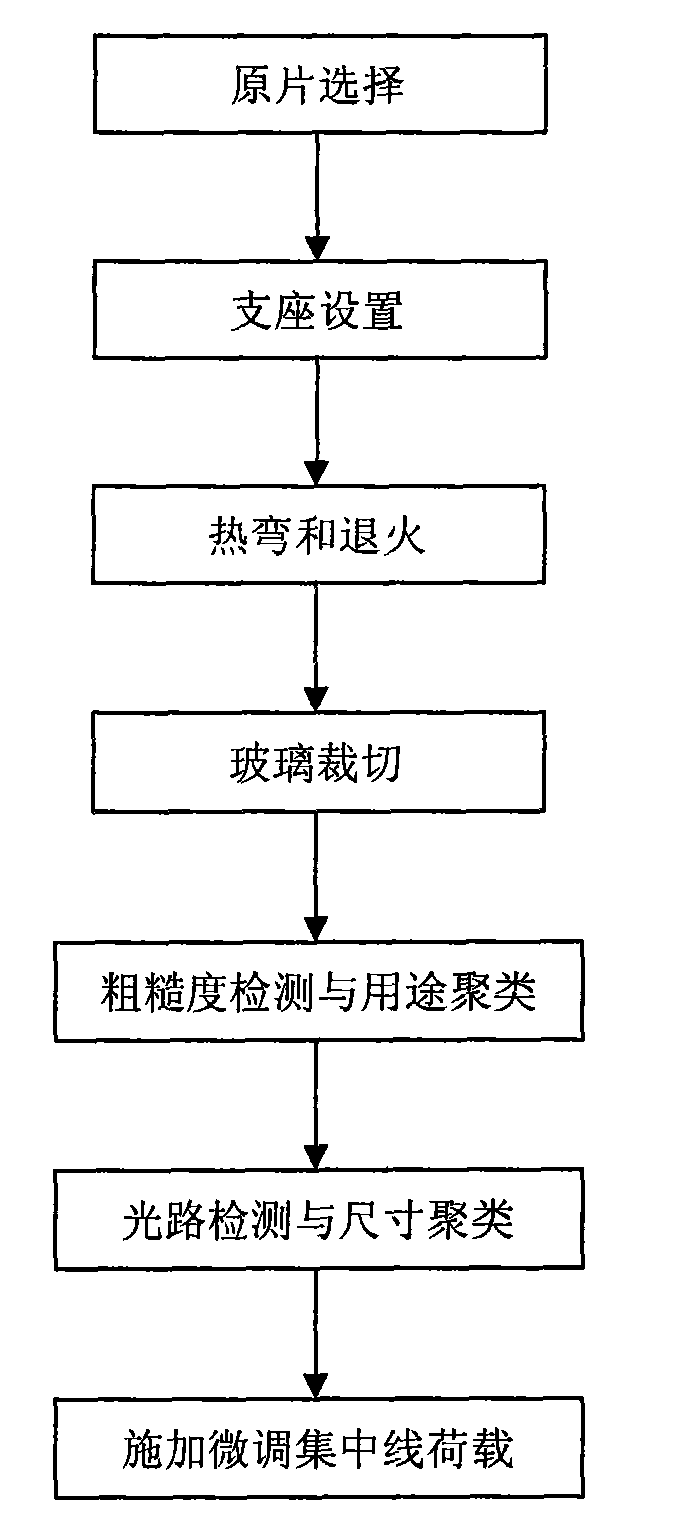

[0042] figure 1 It shows the flow of a manufacturing method of a curved cylindrical reflective concentrator for a line-focusing solar system, including the following steps: original sheet selection, support setting, thermal bending and annealing, glass cutting, surface roughness detection and use Clustering, optical path detection and size clustering, applying concentrated loads.

[0043] Selection of the original film: select the mirror-grade 3.2mm thick float glass 1 as the original film for processing. Glass below 3mm and above 14mm is not suitable for processing the original film of the condenser lens. Choose thinner glass within this range to reduce radiation absorption loss and obtain a smaller focal length to aperture ratio. After cleaning and drying the original glass sheet, randomly select 10 measuring points per square meter on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com