Reinforced type core plate structure and manufacturing method thereof

A production method and enhanced technology, applied to snowboards, sports accessories, sleds, etc., can solve the problems of large weight and volume of sports skateboards, low comprehensive mechanical properties, etc., to achieve easy driving and control of skateboards, and better comprehensive mechanical properties , The effect of convenient storage and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

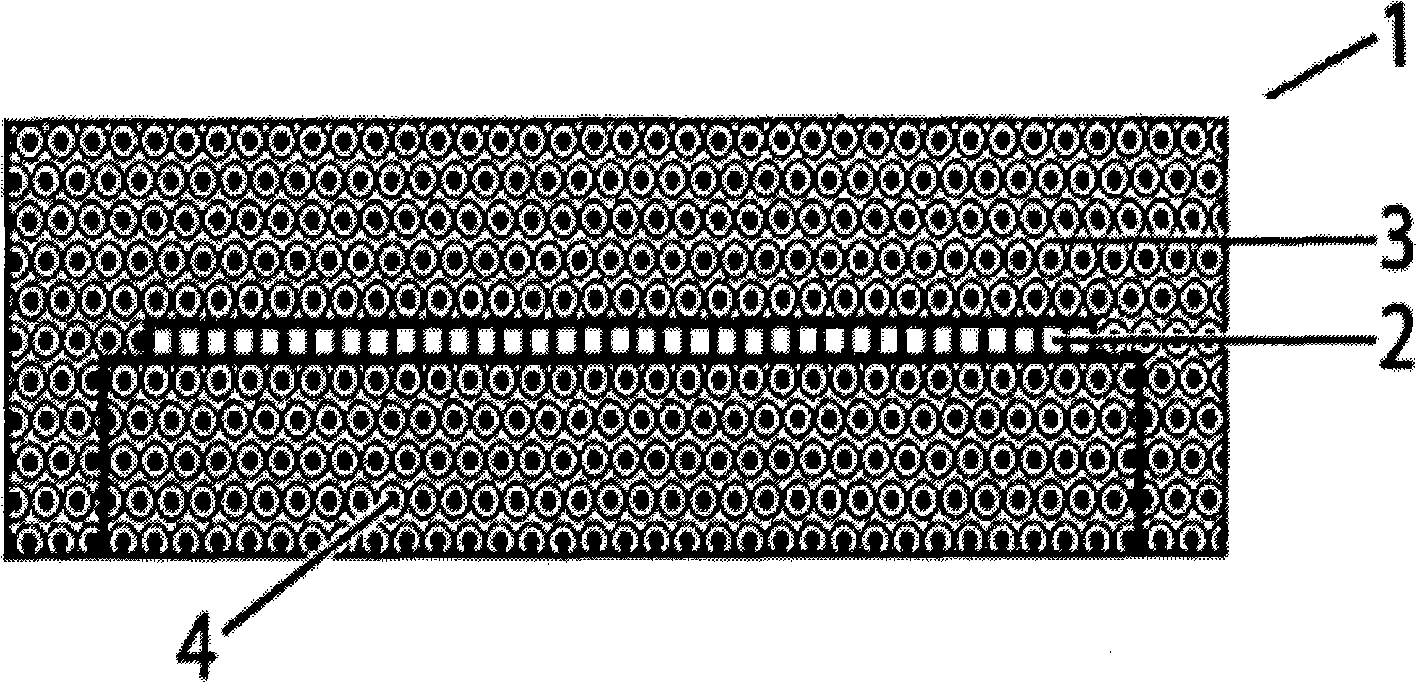

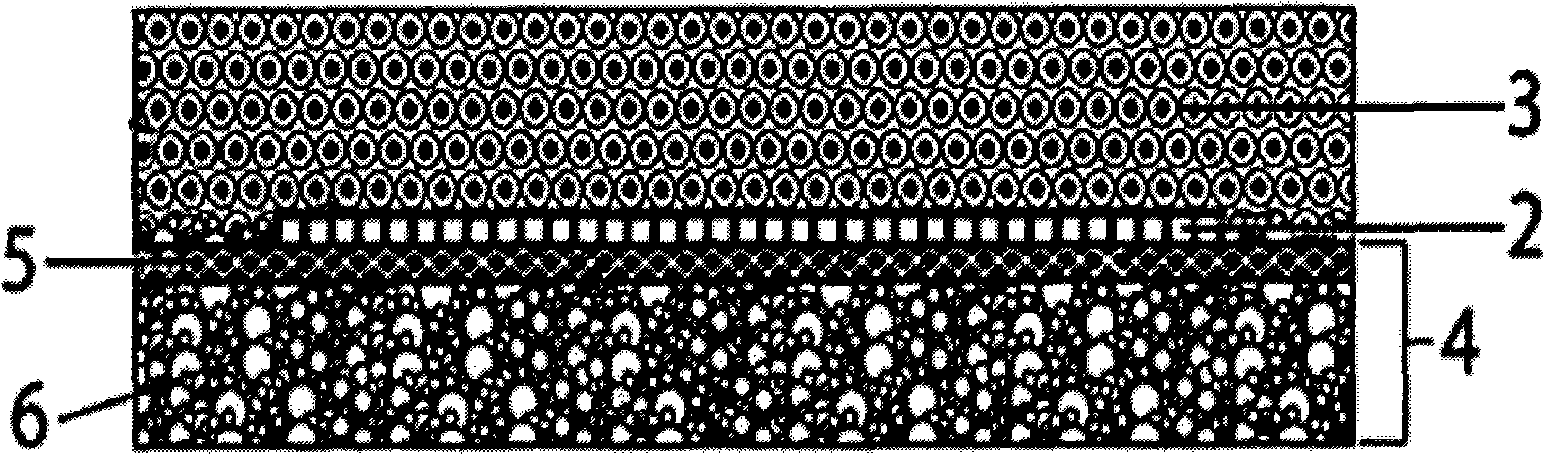

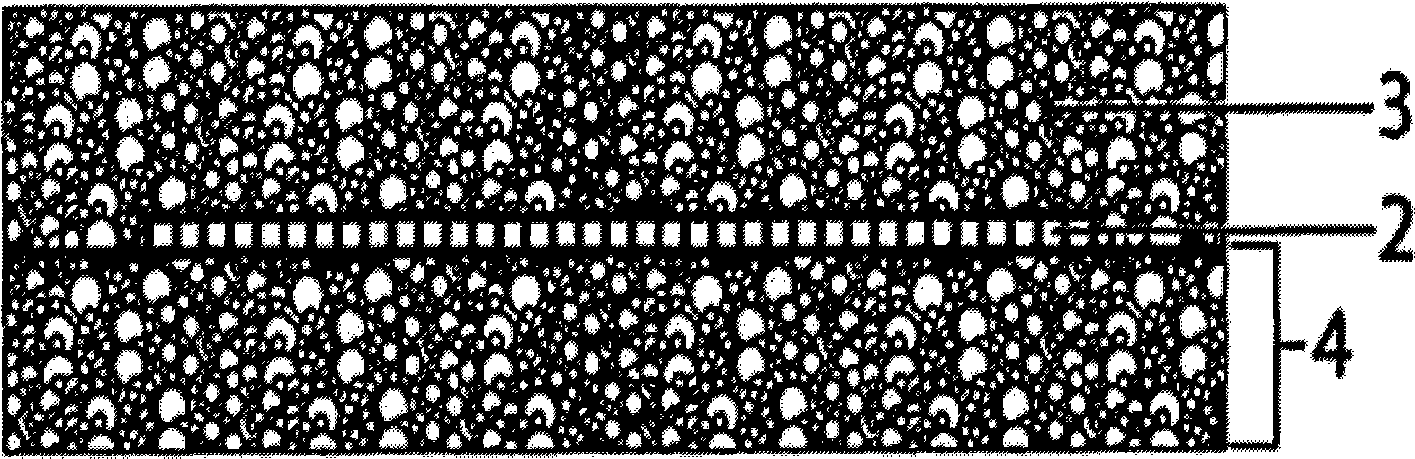

[0032] figure 1 The basic structure of the first embodiment of the core plate of the present invention is shown. The reinforced core plate structure includes a core plate 1 of a layer of expanded polystyrene (EPS) material, and a core plate is arranged in the middle of the core plate. A plastic hollow board 2 made of polypropylene (PP) material that is light in weight, good in elasticity, and not easily deformed. The plastic hollow board is arranged at about two-thirds of the thickness from the upper surface of the core board 1 to the lower surface thereof, the thickness of the plastic hollow board 2 is 3-30mm, and the thickness of the board wall is 0.1mm-5mm. The plastic hollow board 2 is embedded in the core board 1, and the upper and lower surfaces and the periphery of the plastic hollow board 2 are wrapped by the core board material (see Figure 4 ), in order to prevent the core board from being made into a sports skateboard, the corners of the plastic hollow board 2 are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com