Sheet glass laminate structure and multiple sheet glass laminate structure

A technology of plate glass and structure, applied in the direction of glass/slag layered products, layered products, textiles, etc., can solve problems such as insufficient strength or thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

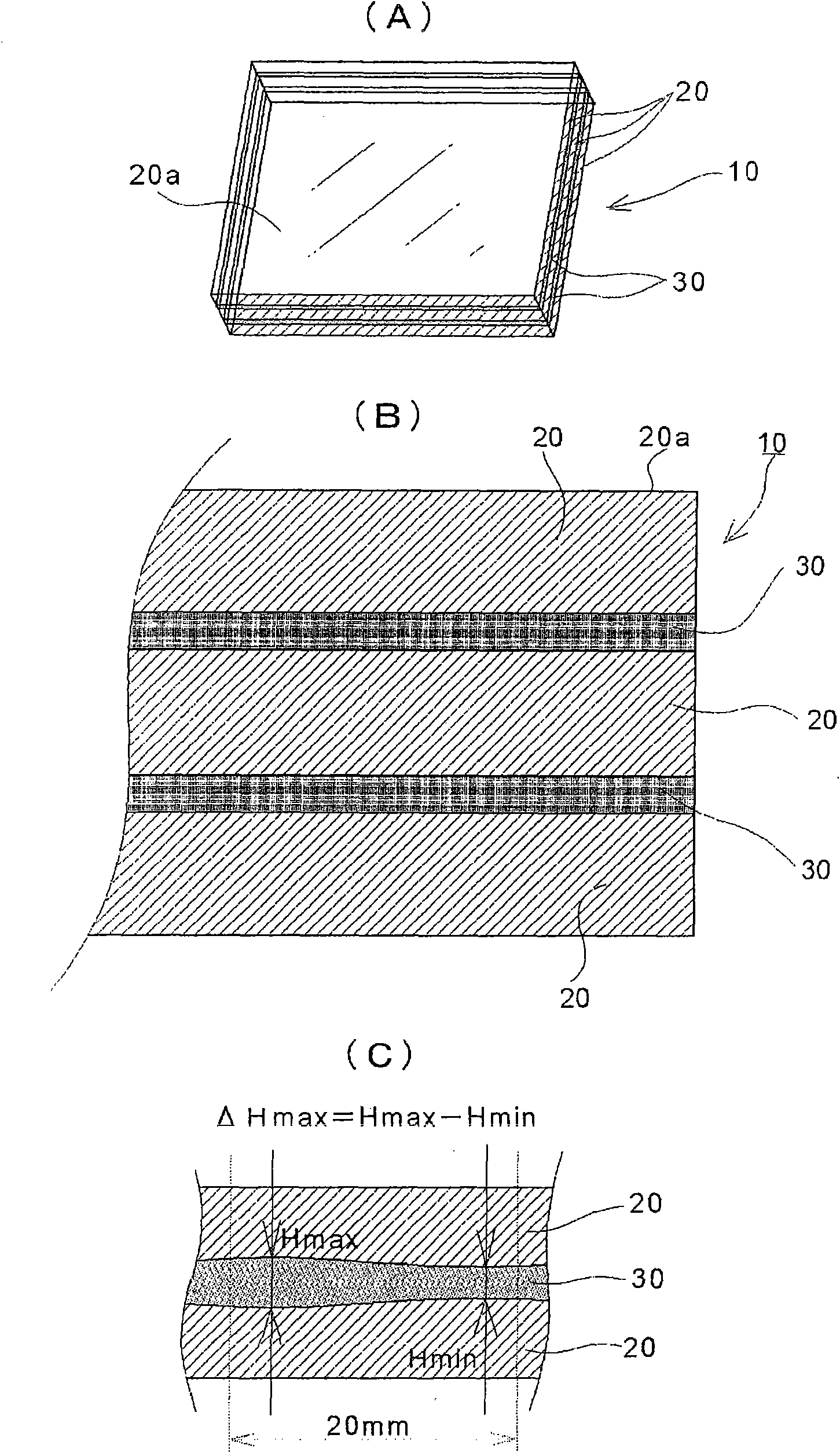

[0081] exist figure 1 and figure 2 In , the explanatory diagram and perspective view are shown about the sheet glass laminated structure 10 of this invention of this invention. figure 1 (A) is a three-dimensional overall view, figure 1 (B) is a partial sectional view, figure 1 (C) is figure 1 (B) An enlarged cross-sectional view of the main part of the figure. In these figures, 20 denotes each sheet glass constituting the sheet glass laminated structure, 20a denotes a light-transmitting surface, and 30 denotes an intermediate layer interposed between the sheet glasses.

[0082] This sheet glass laminated structure 10 is, from figure 1 (A), figure 1 (B) It can be seen that three sheet glasses 20 with a thickness of 0.7 mm are stacked in an edge-aligned manner, and each sheet glass 20 has a light-transmitting surface area of 300 mm in length and 500 mm in width. The compositions of the three sheet glasses 20 are all expressed in terms of mass percent in terms of oxides...

Embodiment 2

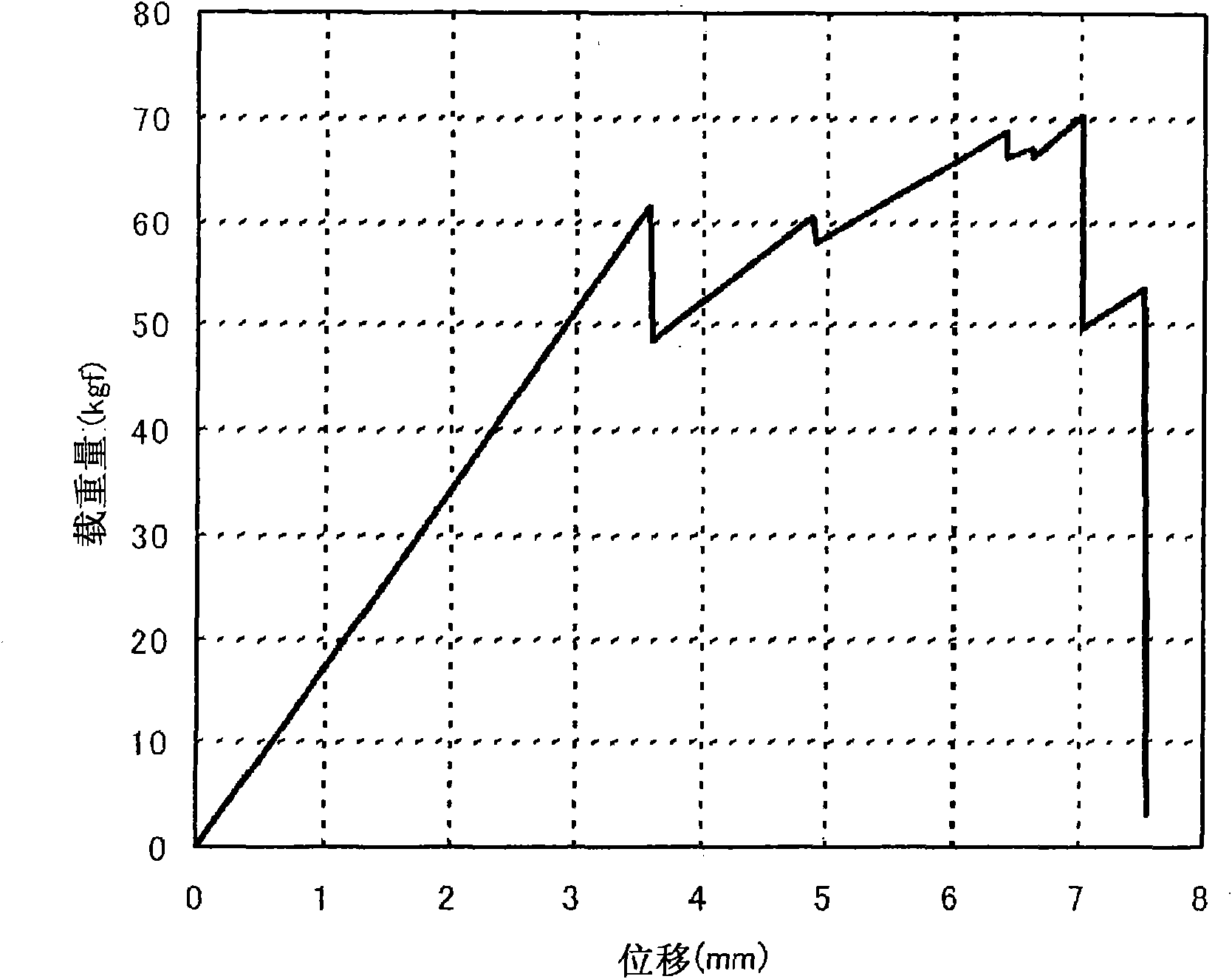

[0093] In order to evaluate the performance of the plate glass laminate structure of the present invention regarding the load deformation behavior of the three-point bending test using the plate glass laminate structure, a liquid crystal having a light-transmitting surface area of 50 mm in length and 180 mm in width and a thickness of 0.7 mm was prepared. Sheet glass curved out-of-spec products. Since this sheet glass is stacked in 4, 5, and 6 layers, ethyl polyvinyl acetate (EVA) resin with a thickness of 0.25 mm is prepared with the same size as the sheet glass. Sheets, polyvinyl butyral (PVB) resin sheets with a thickness of 0.38mm and 0.76mm, and then sandwich the resin sheet between the laminated glass sheets to form a laminated structure of the sheet glass and the resin sheet. In addition, the laminated structure of the plate glass and the resin sheet is sandwiched by the abutting surface of the aluminum plywood that has been subjected to a curved surface treatment of ...

Embodiment 3

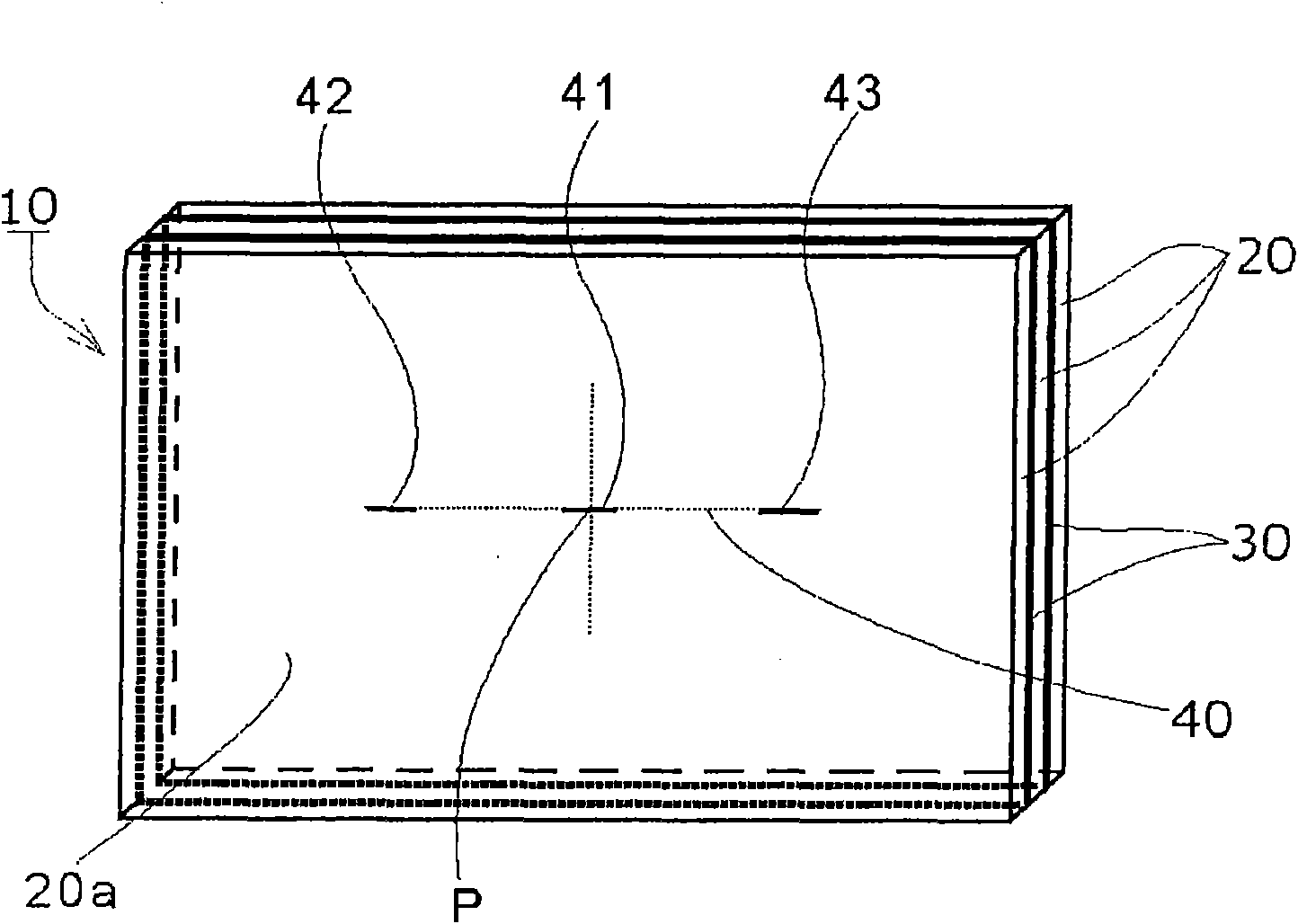

[0105] Next, another sheet glass laminated structure of the present invention is shown below.

[0106] Image 6A partial sectional view showing another sheet glass laminated structure 11 of the present invention. This sheet glass laminated structure 11 is a sheet glass 21 of borosilicate glass that has been strengthened, has a light-transmitting surface with a size of 300 mm x 400 mm, a plate thickness of 0.6 mm, and surface undulations in a section of 20 mm in length. In the state of exceeding 20 μm. In addition, as the intermediate layer 31 between each sheet glass, it laminated|stacked through the intermediate layer 31 which consists of the polyvinyl butyral resin sheet which disperse|distributed and mixed the translucent alumina filler, and the thickness dimension was 0.38mm.

[0107] In addition, the further structural feature of the sheet glass laminated structure 11 is that, on one side of the sheet glass laminated structure 11, the thin sheet glass (second sheet glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com