Method for manufacturing organic electroluminescent display device

An electroluminescence display, organic technology, applied in the direction of electric solid device, semiconductor/solid state device manufacturing, electrical components, etc., can solve the problems of low luminous efficiency, poor performance stability, low luminous brightness, etc., to achieve simple preparation process, luminous The effect of strength enhancement and overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

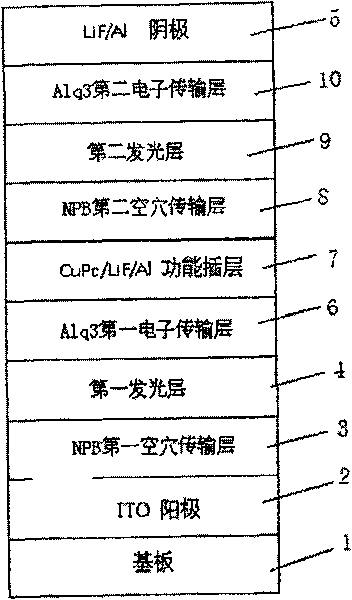

[0018] A method for preparing an organic electroluminescence display device includes the following steps:

[0019] 1) Print the indium tin oxide ITO anode 2 pattern of the organic electroluminescence display device OLED on the cleaned conductive substrate 1, and the substrate with the printed indium tin oxide ITO anode 2 pattern is ultrasonically cleaned with toluene, ethanol and acetone respectively. Dip and rinse with deionized water. Finally, an ozone ion bombardment treatment was performed in a vacuum chamber, the pressure was controlled at 50 Pa, and the substrate was bombarded for 20 minutes.

[0020] 2) Use vacuum evaporation method to evaporate hole transport layer material N,N'-bis(1-naphthyl)-N,N'-diphenyl- on the substrate with printed indium tin oxide ITO anode 2 pattern. 1,1'-Diphenyl-4,4'-diamine, referred to as NPB, prepares the first hole transport layer 3 of NPB, and the system vacuum is 5×10 -5 Pa, NPB deposition rate is 0.1nm / s, thickness is 80nm.

[0021] 3) On ...

Embodiment 2

[0030] A method for preparing an organic electroluminescence display device includes the following steps:

[0031] 1) Print the indium tin oxide ITO anode 2 pattern of the organic electroluminescence display device OLED on the cleaned conductive substrate 1, and the substrate with the printed indium tin oxide ITO anode 2 pattern is ultrasonically cleaned with toluene, ethanol and acetone respectively. Then immerse and rinse with deionized water, and then rinse with deionized water, then rinse with deionized water, then use toluene, ethanol and acetone for ultrasonic cleaning, and then rinse with deionized water, and finally in the vacuum chamber Carry out ozone ion bombardment treatment, control the pressure between 5 Pa, and bombard the substrate for 5 minutes.

[0032] 2) Use vacuum evaporation method to evaporate hole transport layer material N,N'-bis(1-naphthyl)-N,N'-diphenyl- on the substrate with printed indium tin oxide ITO anode 2 pattern. 1,1'-Diphenyl-4,4'-diamine, refer...

Embodiment 3

[0042] A method for preparing an organic electroluminescence display device includes the following steps:

[0043] 1) Print the indium tin oxide ITO anode 2 pattern of the organic electroluminescence display device OLED on the cleaned conductive substrate 1, and ultrasonically clean the substrate with the printed indium tin oxide ITO anode 2 pattern in deionized water with detergent , Then rinse with deionized water, then ultrasonically clean with toluene, ethanol, and acetone, then rinse with deionized water, and finally perform ozone ion bombardment treatment in a vacuum chamber, control the pressure at 30Pa, and perform the substrate Bombard for 15min.

[0044] 2) Use vacuum evaporation method to evaporate hole transport layer material N,N'-bis(1-naphthyl)-N,N'-diphenyl- on the substrate with printed indium tin oxide ITO anode 2 pattern. 1,1'-Diphenyl-4,4'-diamine, referred to as NPB, prepares the first hole transport layer 3 of NPB, and the system vacuum is 5×10 -5 Pa, NPB dep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| luminance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com