Full-membrane wall circulating fluidized bed boiler without corridor corner tube

A circulating fluidized bed and membrane wall technology, which is applied in water tube steam boilers, fluidized bed combustion equipment, boiler water pipes, etc. , increase the power consumption of the induced draft fan, etc., to achieve the effect of saving refractory materials, easy on-site installation, and good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

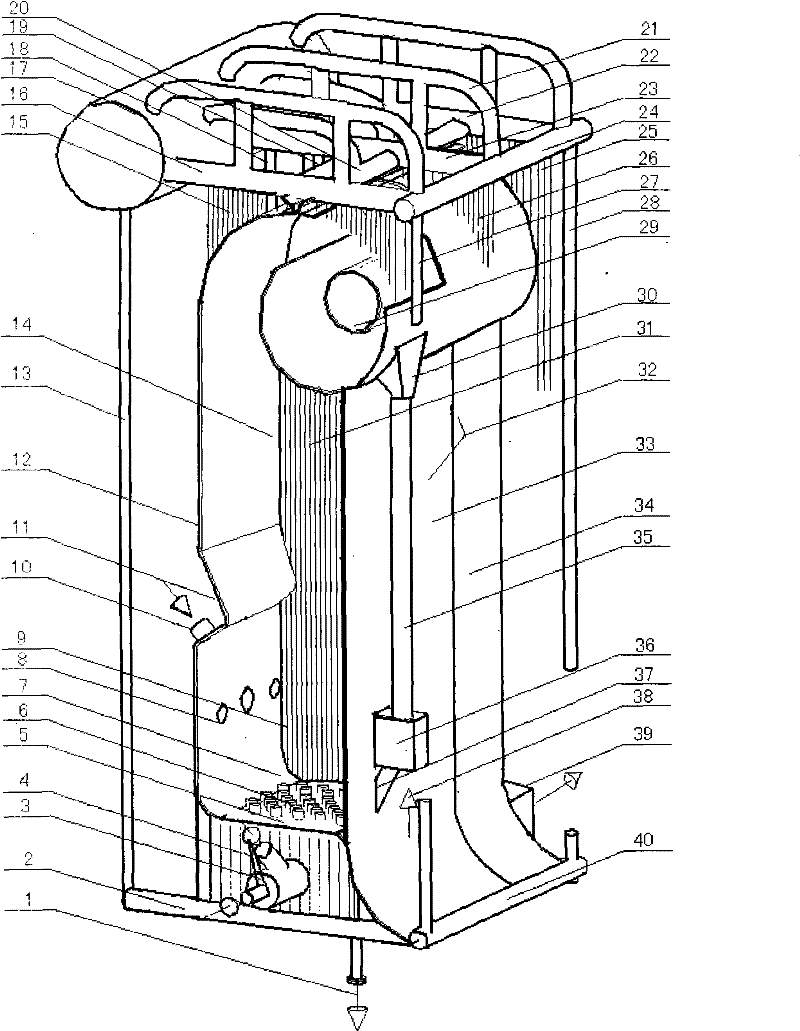

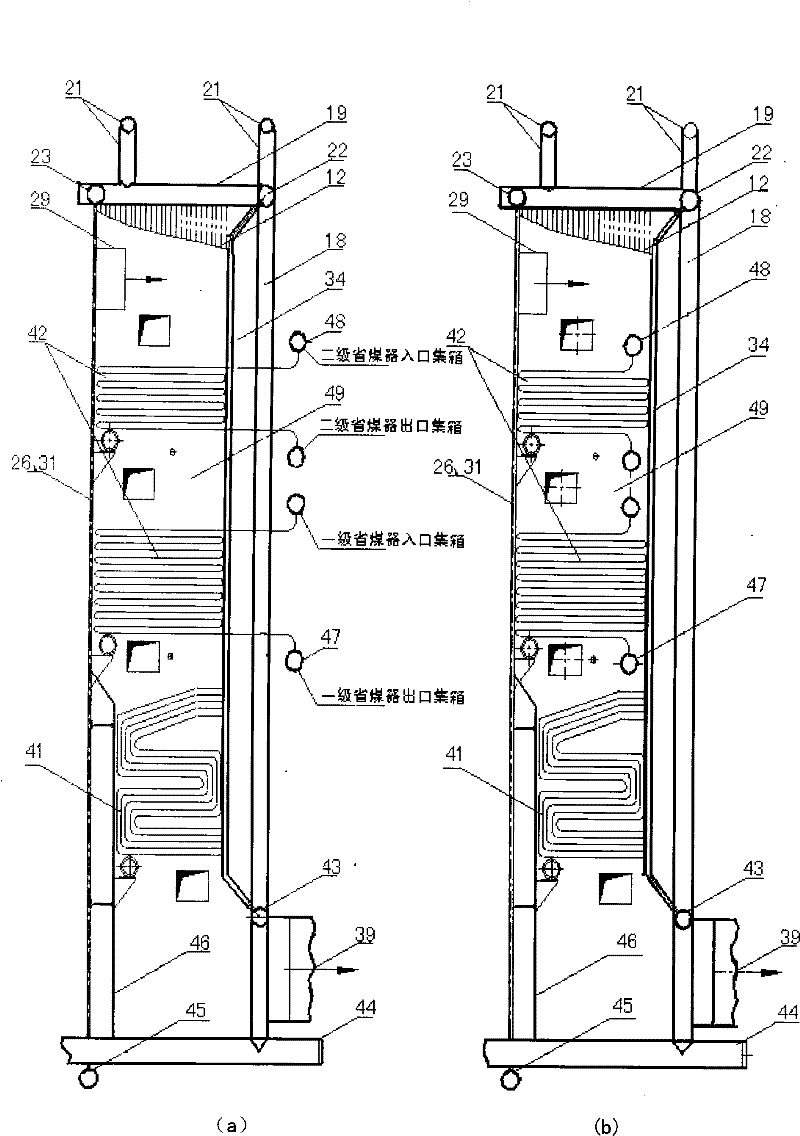

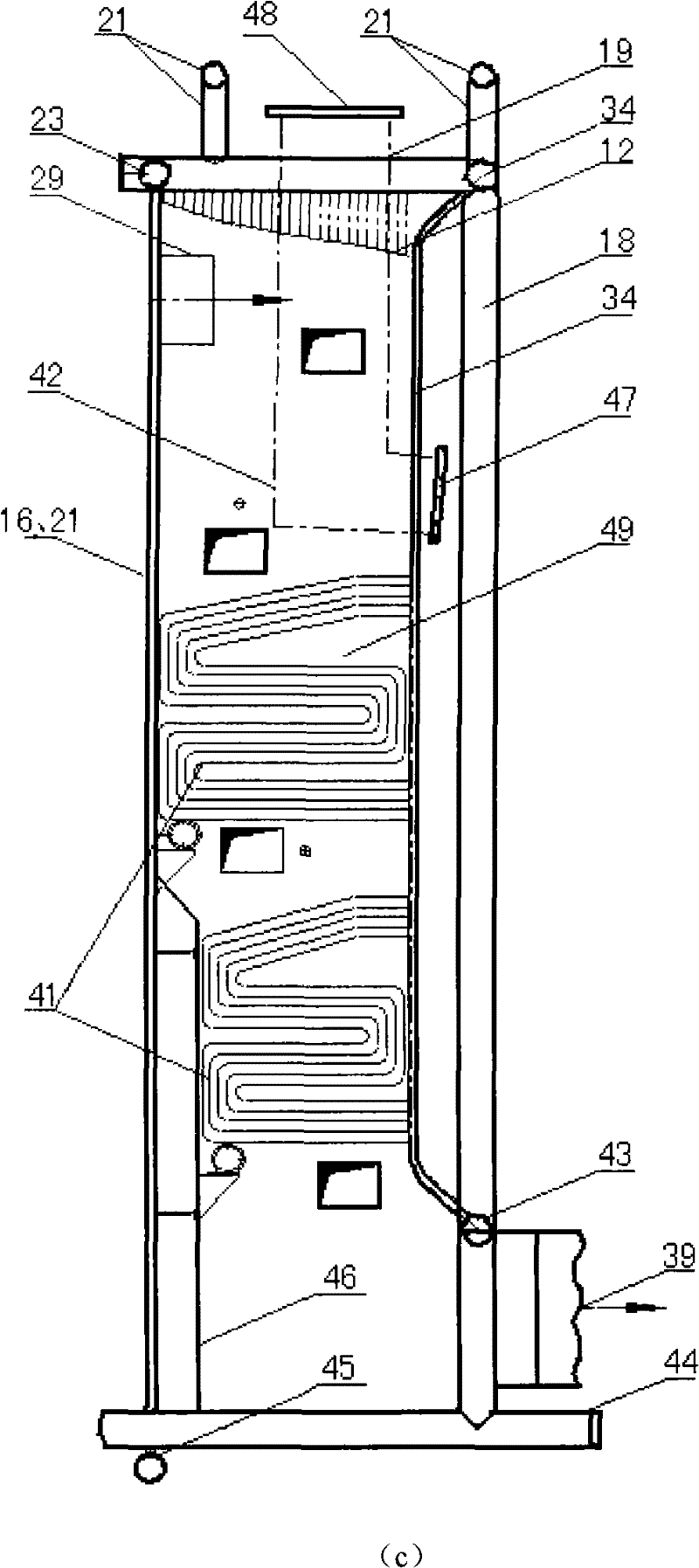

[0036] The structural principle and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] see figure 1 , figure 2 , the present invention includes the corner tubes 13, 18, 27, 28 arranged at the four corners of the boiler furnace, the lower headers 2, 40 at the bottom of the furnace and the upper headers 16, 19, 20, 22, 23, 24 at the top of the furnace, and the horizontal The frame-type self-supporting structure system composed of a single drum 17 is connected to the front wall membrane water wall 12 and the rear wall of the upper header 16, 19, 20, 22, 23, 24 and the lower header 2, 40 through corner joints. Wall membrane water cooling wall 32, left wall membrane water cooling wall 25, right wall membrane water cooling wall 15, double-sided exposure membrane water cooling wall 26, 31 heating surface and arranged in the convection shaft 49 left wall membrane water cooling wall The flag-type tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com