Resin film formation method and resin film formation device

A resin film and substrate technology, which is applied in the manufacture of optical record carriers and optical record carriers, can solve the problems of difficult irradiation of radiation, difficult resin film thickness, large-scale devices, etc., and achieve the effect of improving irradiation efficiency and clear boundaries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

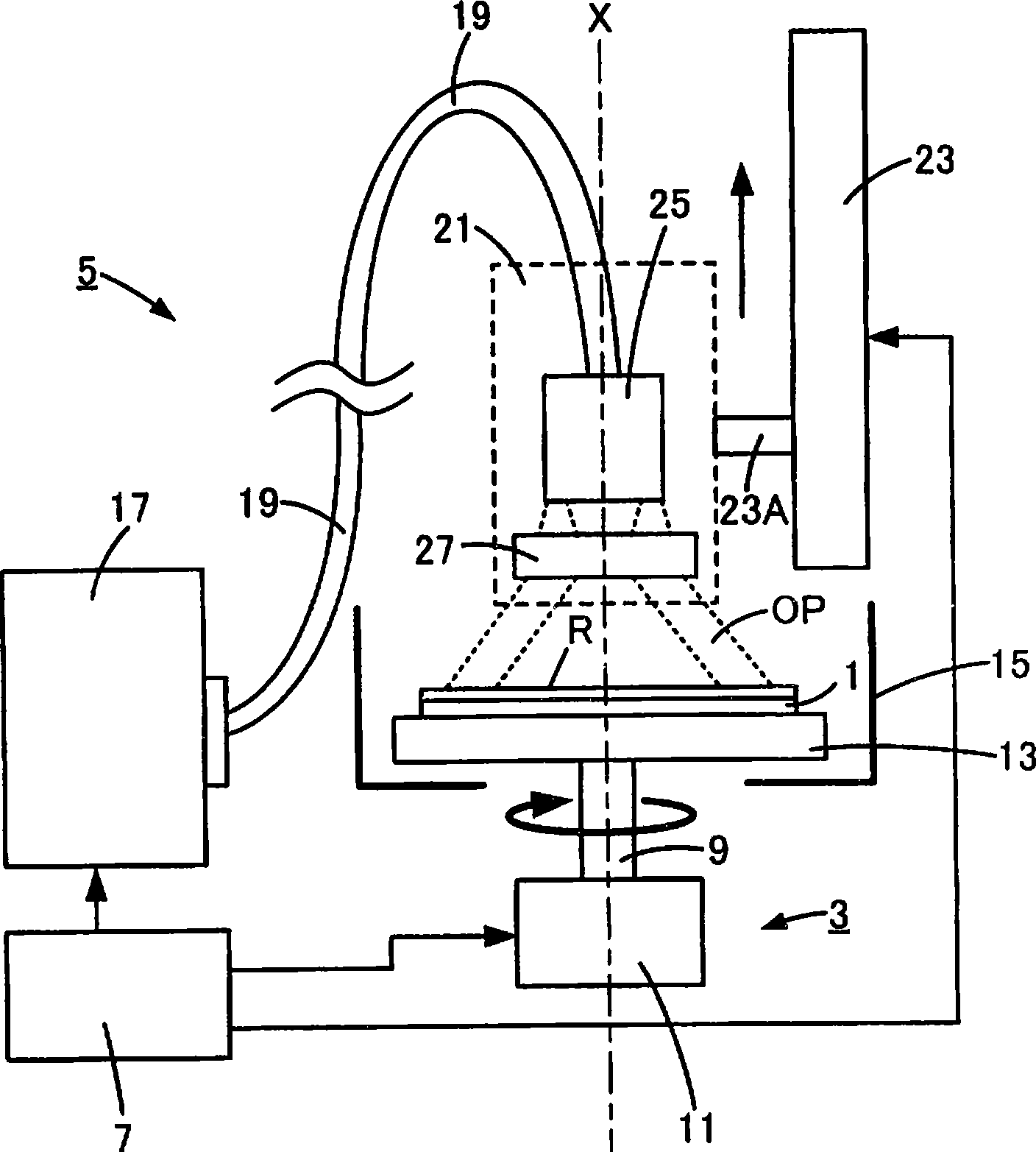

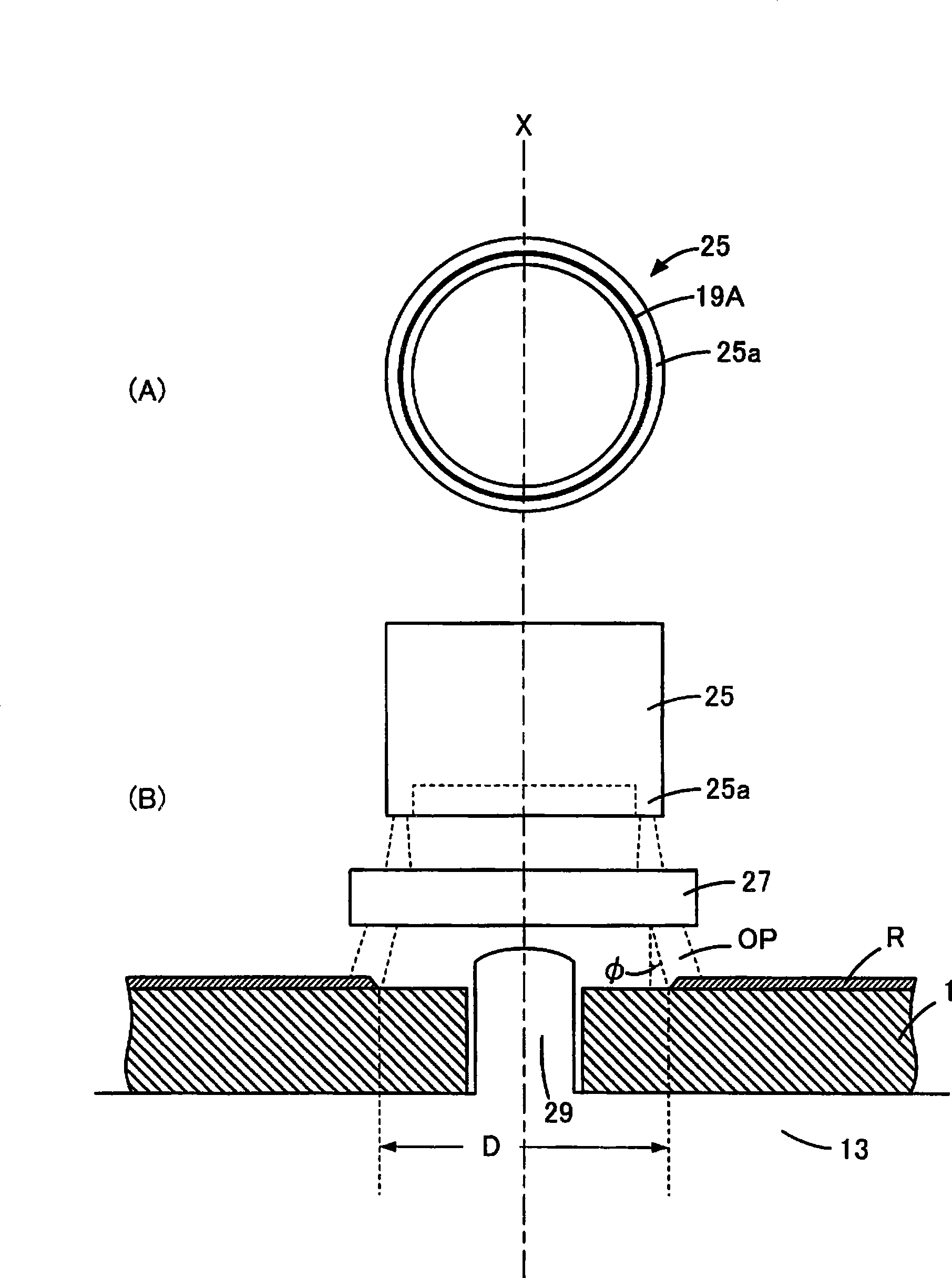

[0048] pass Figure 1 to Figure 4 The resin film forming method and resin film forming apparatus according to Embodiment 1 of the present invention will be described. figure 1 It is a figure for explaining the resin film forming apparatus of Embodiment 1 of this invention, figure 2 It is a figure which shows the lower surface of the light irradiation part. image 3 It is a figure for explaining the circular light irradiated on the board|substrate, Figure 4 It is a figure which shows an example of the rotation pattern of a board|substrate, and the raising speed pattern of an optical irradiation head. First, through figure 1 The outline of this resin film forming apparatus will be described. The resin film forming apparatus includes: a substrate rotation mechanism 3 for rotating a substrate 1 such as a second-generation large-capacity optical disc around a rotation center X according to a selected rotation pattern; A light irradiation mechanism 5 for irradiating annular ul...

Embodiment approach 2

[0062] according to Figure 5 and Figure 6 Embodiment 2 of the present invention will be described. Figure 5 It is a figure which shows an example of the light irradiation mechanism used for the resin film forming apparatus of Embodiment 2, Figure 6 It is a figure which shows the partial cross section of 25 A of ring-shaped light irradiation parts of 5 A of light irradiation mechanisms. exist Figure 5 and Figure 6 in, with in Figure 1 to Figure 4 The reference numerals used in the same reference numerals denote the components of the same name. The light irradiation head 21A shown by the dotted line is composed of the front end portion of the optical cable 19 bundled with a plurality of optical fibers and the annular light irradiation part 25A. The annular light irradiation part 25A is composed of the first annular light forming part 31 and the second annular light The light forming part 33 is constituted, and the above-mentioned first ring-shaped light forming part...

Embodiment approach 3

[0067] according to Figure 7 A resin film forming apparatus according to Embodiment 3 of the present invention will be described. exist Figure 7 in, with in Figure 1 to Figure 6 The reference numerals used in the same reference numerals denote the components of the same name. Embodiment 3 is characterized in that the photoirradiation head 21B indicated by the dotted line on the photoirradiation mechanism 5B, in particular, the annular light OP output from the photoirradiation head 21B is irradiated on the substrate 1 after being intersected. By enlarging the head 21B, ring-shaped light OP with higher light intensity can be obtained. This light irradiation head 21B is made up of the following parts: the front end part of optical cable 19; The lens member 27 that is disposed opposite to the front end surface vicinity of optical cable 19; The first reflection member 35; Member 37. The lens member 27 is, for example, a lens member called a collimator lens, which makes the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| absorption wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com