Plate heat exchanger

A technology of heat exchanger and heat conduction, which is applied in the field of adsorption device and heat exchanger, can solve the problems that hinder the development of mobile air conditioning units, and achieve the effect of compact size, low weight and reduced thermal mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

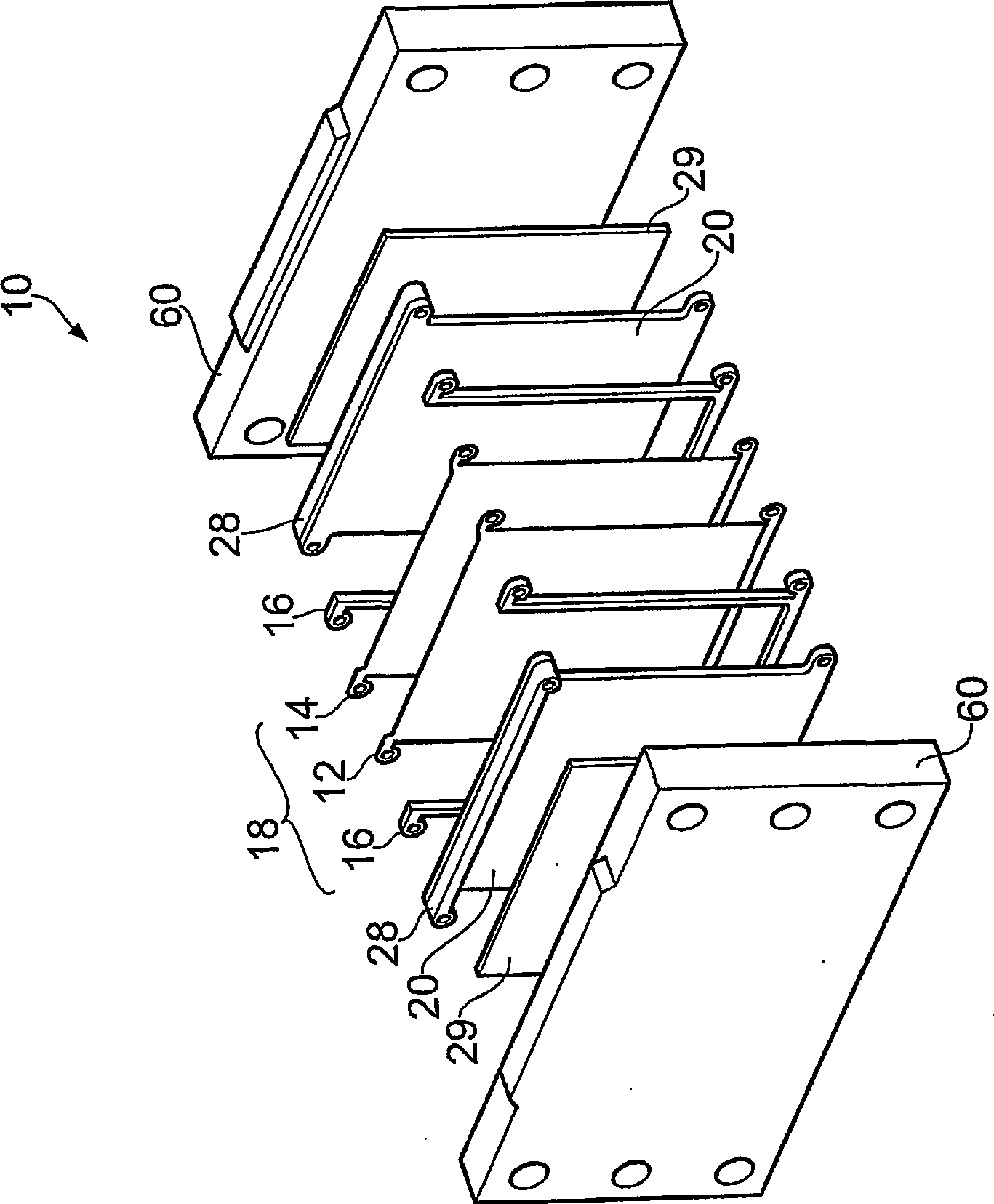

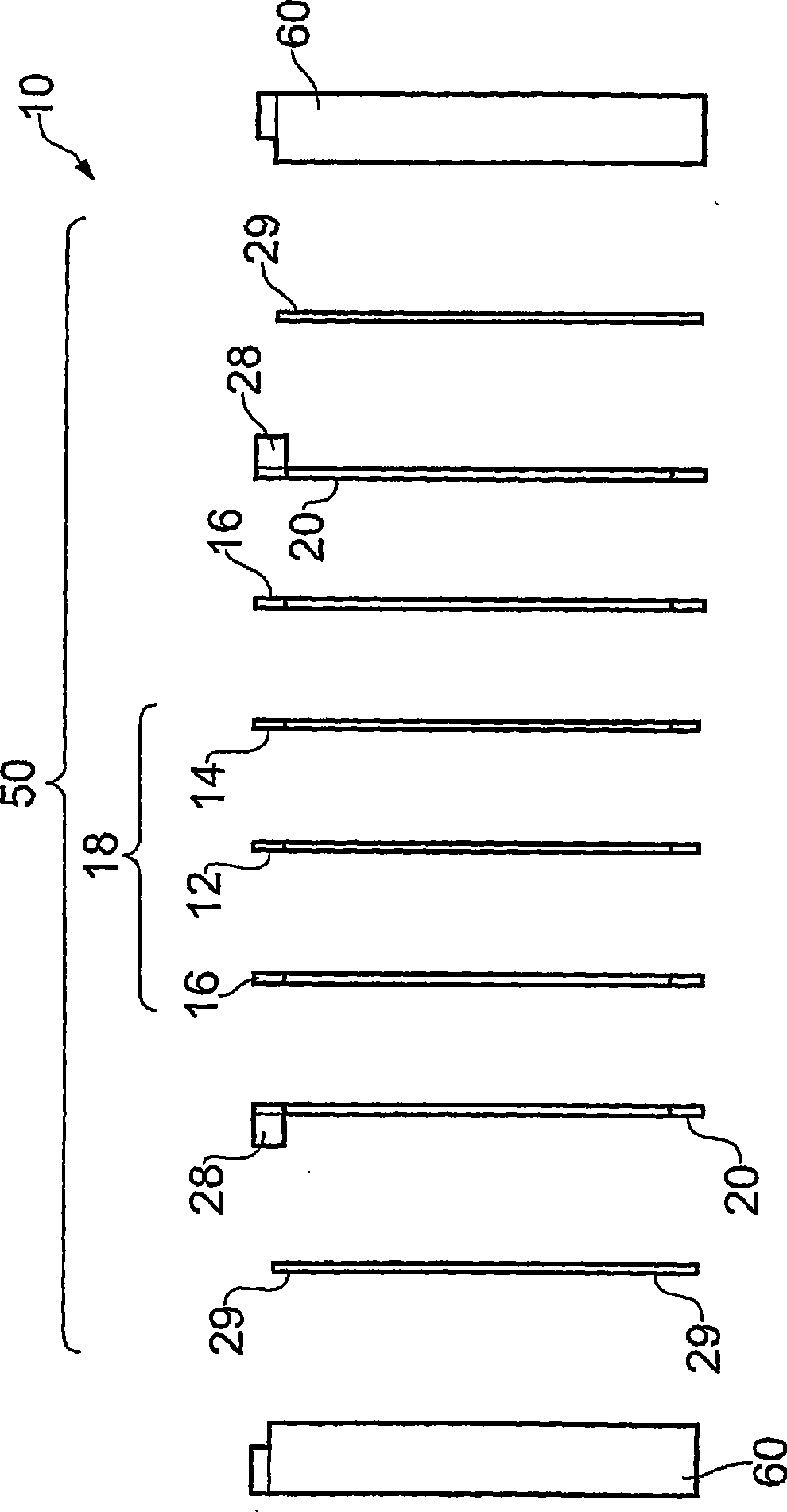

[0118] According to the first embodiment of the present invention, the plate heat exchanger 10 such as figure 1 (perspective view) and figure 2 (side view) settings shown.

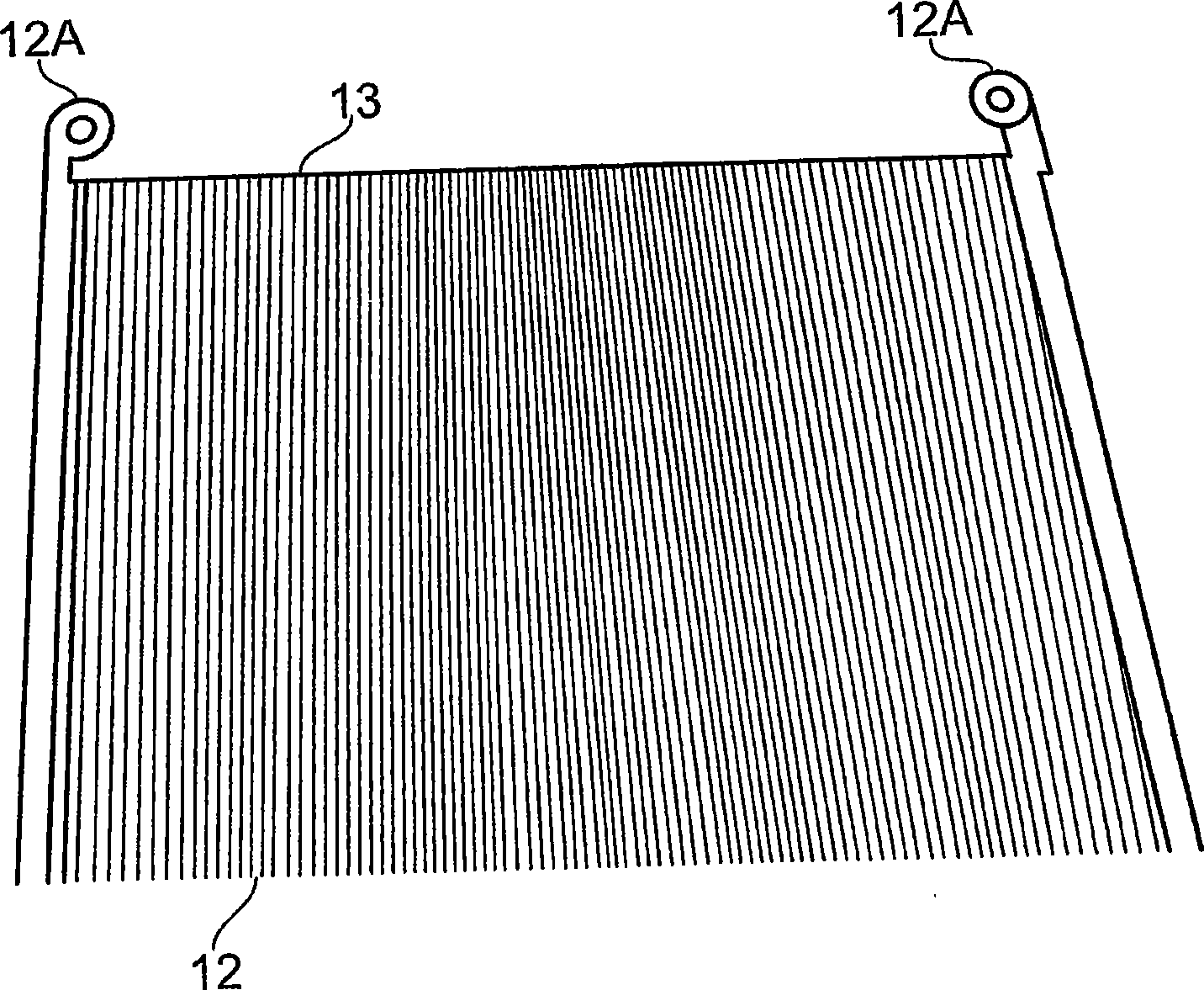

[0119] The heat exchanger 10 comprises a 0.7 mm thick stainless steel etched plate element 12 sandwiched between a 0.1 mm thick stainless steel flat plate 14 and a 4 mm thick "U" shaped gasket 16 .

[0120] Spacer 16 is laser cut from stainless steel plate. The etched plate elements 12 , plate elements 14 and spacers 16 form a basic plate member unit 18 which is repeated several times along the length of the heat exchanger 10 . For clarity, in figure 1 and figure 2 Only a single unit 18 is shown in .

[0121] When the heat exchanger is used as a sorption generator, the gasket 16 is packed with activated carbon sorbent (not shown). Many of these repeating units 18 are nickel-copper welded together to form the complete exchanger 10 . When a sufficient number of units 18 (between 20 and 25 for most a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com