LED street lamp heat radiation method and LED street lamp

A technology of LED street lamp and heat dissipation method, which is applied to circuits, lighting and heating equipment, cooling/heating devices of lighting devices, etc., can solve the problems of increasing the heat dissipation area, increasing the weight of lamps, increasing the cost of lamps, etc. Extend the service life and enhance the effect of radiation heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The LED street lamp cooling method of the present invention comprises the following steps:

[0015] a. Coat the outer surface of the PCB board with a layer of radiation cooling paint;

[0016] b. Install the LED on one side of the PCB board, and make the heat dissipation metal part of the LED base close to the PCB board 2;

[0017] c. Stick the other side of the PCB board closely to the inner surface of the lamp housing to form an LED street lamp.

[0018] The radiation cooling paint is ZS-411 radiation cooling paint.

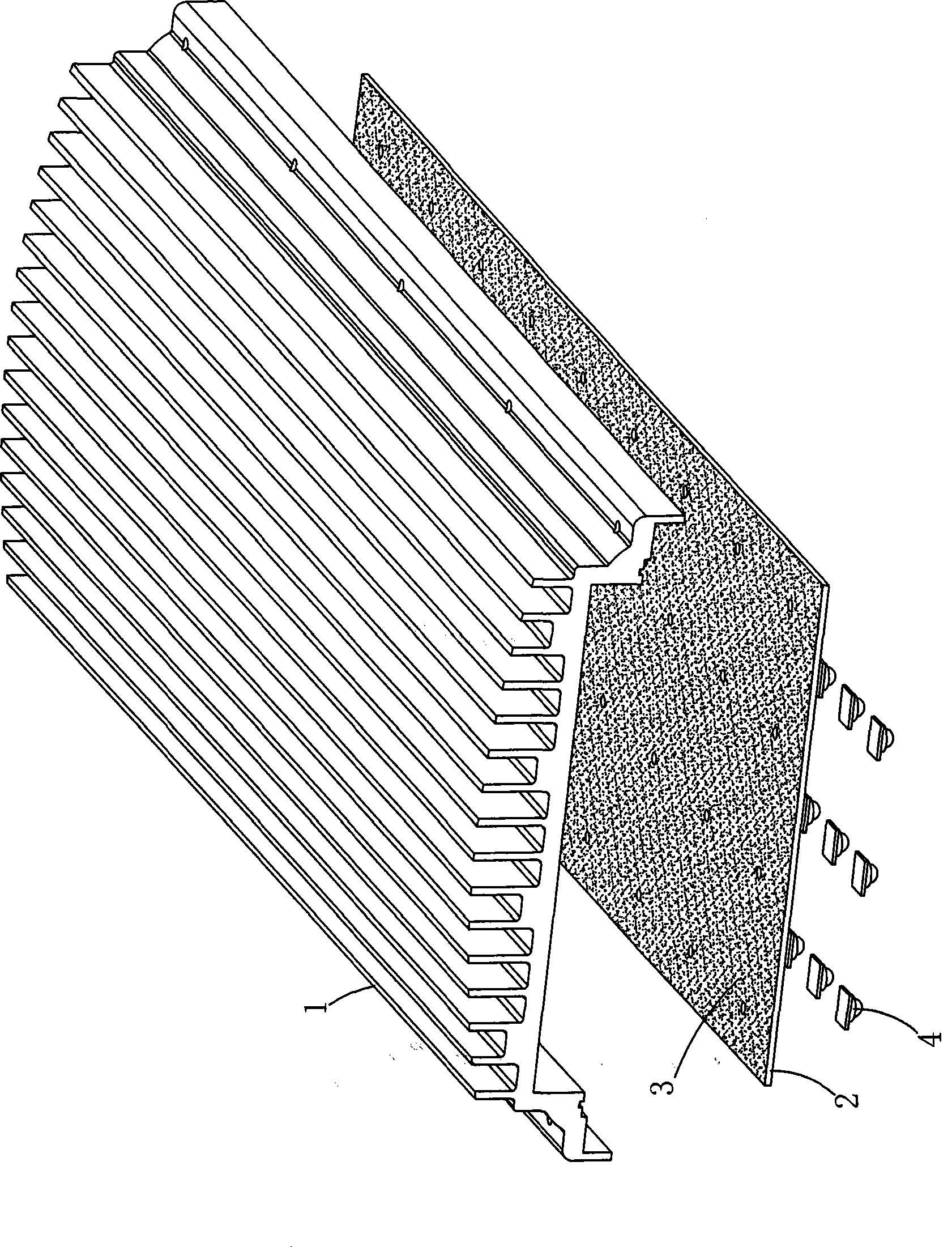

[0019] like figure 1 As shown, the LED street lamp of the present invention includes a lamp housing 1 made of metal material, with a heat sink on the lamp housing 1, a PCB board 2 is arranged inside the lamp housing 1, and the PCB board 2 The outer surface is provided with a radiation heat dissipation cooling paint layer 3, and the radiation heat dissipation cooling paint layer 3 is "ZS-411" radiation heat dissipation cooling paint, which has good cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com