Lithium-containing molten salt creosote thermal transmission heat storage medium, preparation and uses thereof

A carbonic acid molten salt, heat storage medium technology, applied in chemical instruments and methods, heating devices, solar thermal devices, etc., can solve the problems of high melting point and high maintenance cost of molten salt, achieve low melting point, improve heat storage capacity, strengthen The effect of latent heat of phase transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

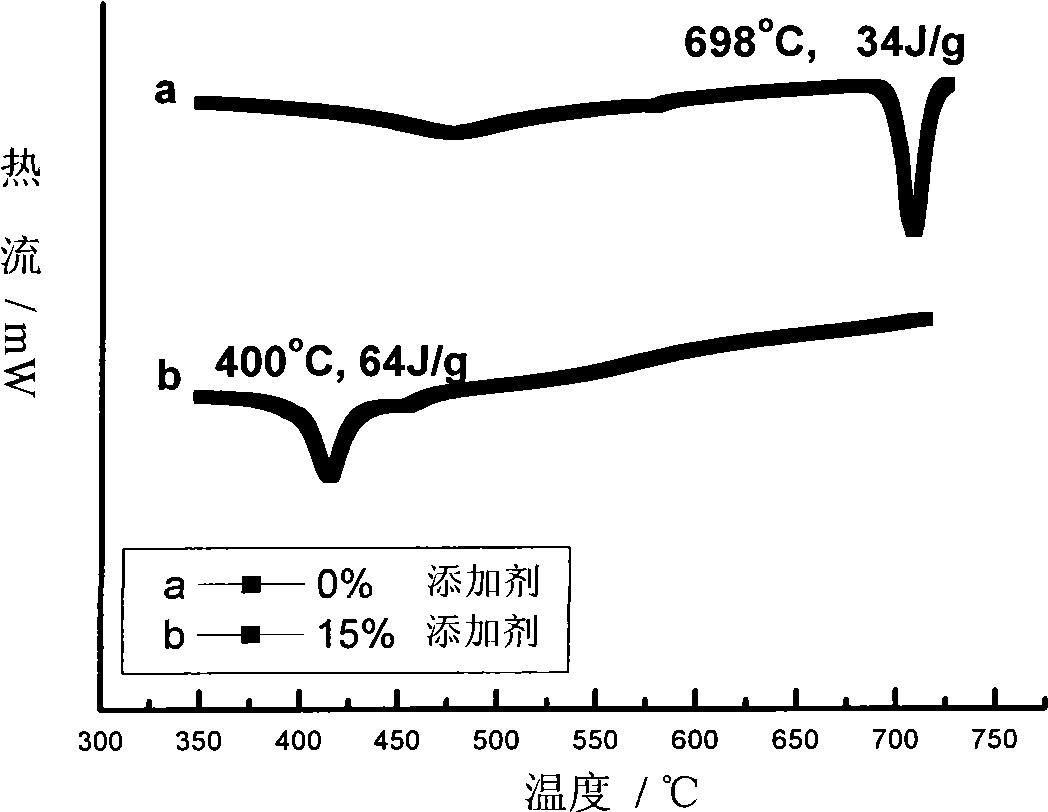

[0035] Mix sodium chloride and lithium carbonate with a mass ratio of 0.02:1 and stir evenly, statically heat until the solids are completely melted, then keep warm for 15 minutes, then naturally cool to room temperature and pulverize to obtain the additive.

[0036] Mix 39% potassium carbonate, 46% sodium carbonate, and 15% additives by mass and stir evenly, heat statically until the solids are completely melted, then keep warm for 10 minutes, then naturally cool to room temperature and pulverize to obtain the lithium-containing Carbonated molten salt heat transfer heat storage medium.

[0037] The melting point, latent heat of phase transition and thermal stability of the prepared lithium-containing carbonate molten salt were measured. The determination was carried out with a general differential scanning (DSC) instrument and a thermogravimetric analysis (TGA) instrument. The DSC curve obtained from the determination is as follows figure 1 Shown in curve b. Adopt the same...

Embodiment 2

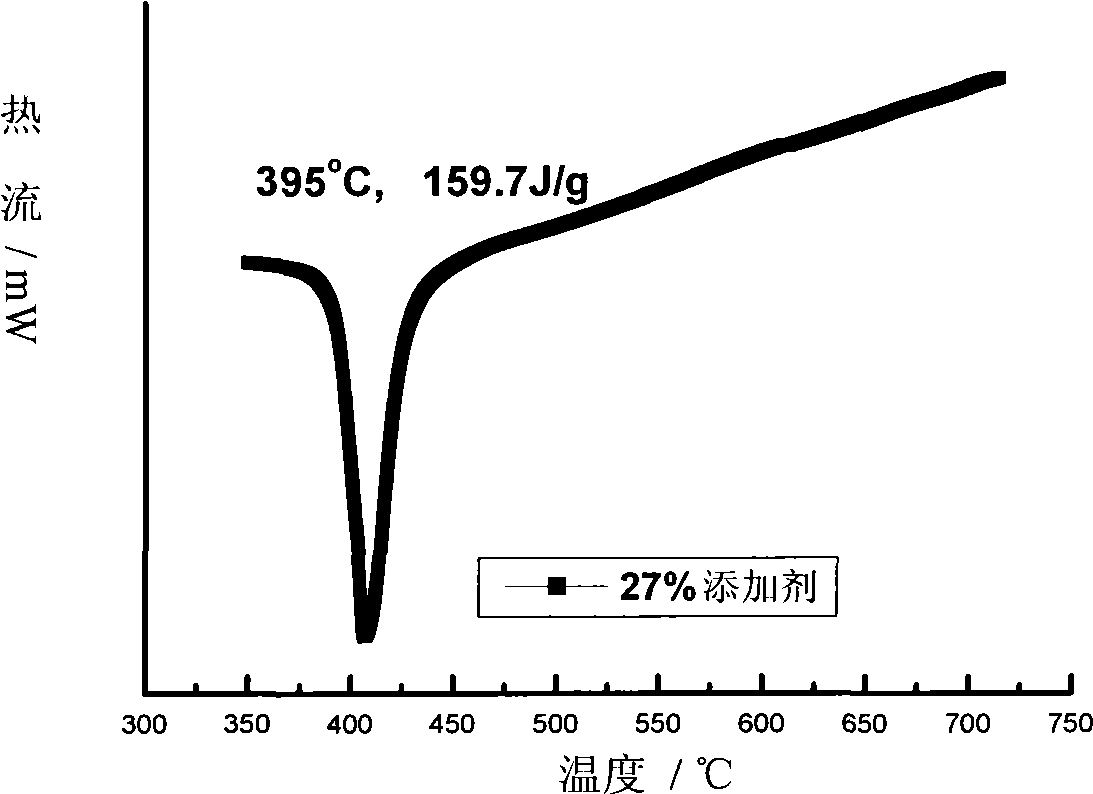

[0042] Mix sodium chloride and lithium carbonate with a mass ratio of 0.12:1 and stir evenly, statically heat until the solids are completely melted, then keep the temperature for 20 minutes, then naturally cool to room temperature and pulverize to obtain the additive.

[0043] Mix 46% potassium carbonate, 36% sodium carbonate, and 18% additives by mass and stir evenly, heat statically until the solids are completely melted, then keep warm for 15 minutes, then naturally cool to room temperature and pulverize to obtain the lithium-containing Carbonated molten salt heat transfer heat storage medium.

[0044] Using the same method as in Example 1, the melting point, latent heat of phase change and thermal stability of the molten salt were measured. The measurement results show that the melting point of the prepared lithium-containing carbonate molten salt is 396°C, the latent heat of phase change is 71J / g, and the temperature corresponding to the 99% residual rate of lithium-cont...

Embodiment 3

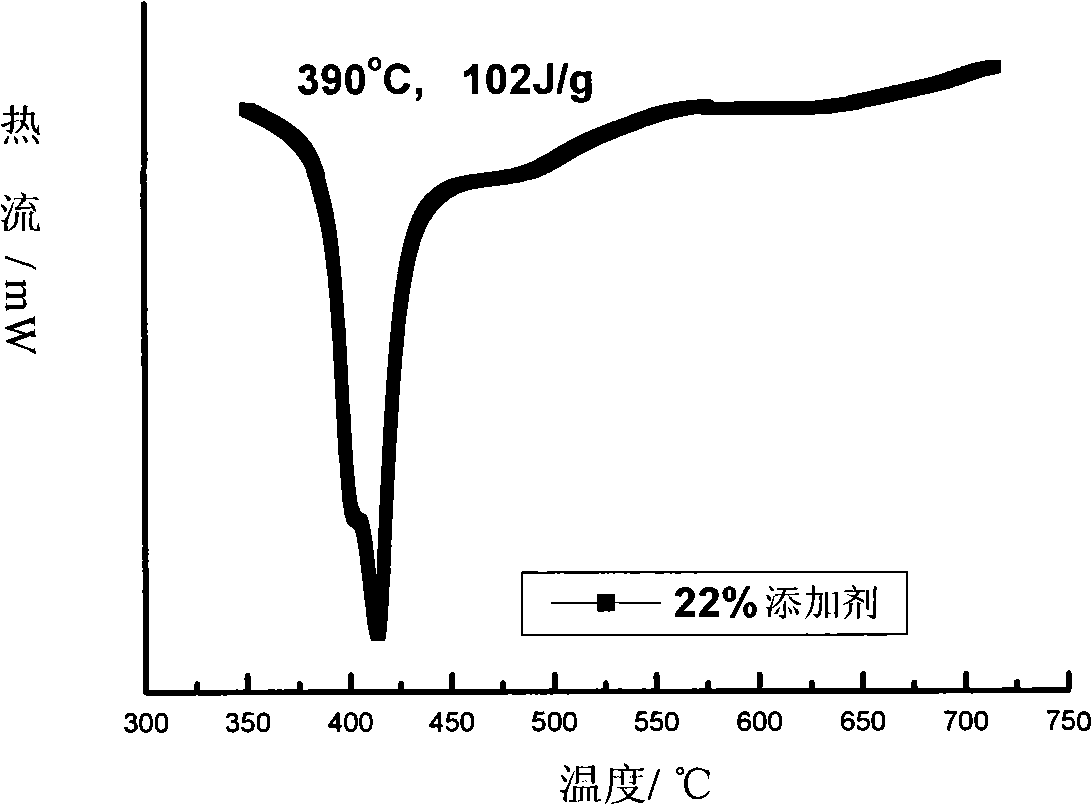

[0046] Sodium chloride and lithium carbonate with a mass ratio of 0.03:1 were mixed and stirred evenly, statically heated until the solids were completely melted, and then kept for 10 minutes, then naturally cooled to room temperature and pulverized to obtain the additive.

[0047] Mix 36% of potassium carbonate, 42% of sodium carbonate, and 22% of the additive by mass and stir evenly, statically heat until the solids are completely melted, then keep the temperature for 25 minutes, then naturally cool to room temperature and pulverize to obtain the Lithium carbonate molten salt heat transfer heat storage medium.

[0048] Using the same method as in Example 1, the melting point, latent heat of phase change and thermal stability of the molten salt were measured. figure 2 It is shown that the melting point of the prepared lithium-containing carbonate molten salt is 390° C., and the latent heat of phase change is 102 J / g. Figure 7 The temperature corresponding to the 99% remain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Latent heat of phase change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com