Glass fiber reinforced polyamide resin composition

A polyamide resin, glass fiber technology, applied in the direction of electrical equipment shell/cabinet/drawer, electrical components, etc., can solve problems such as deterioration and hinder the surface appearance of metal molds, to ensure fluidity, excellent surface appearance, and suppress burrs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

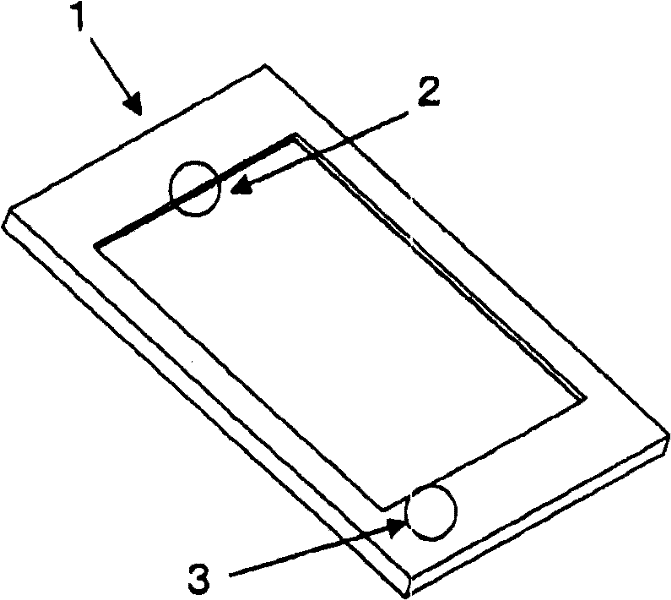

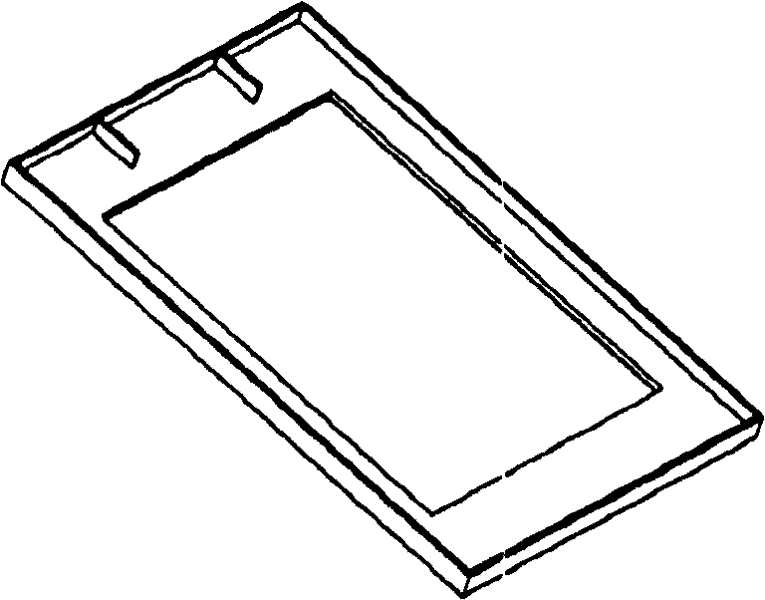

Image

Examples

reference example 1

[0060] (Reference example 1): Amorphous polyamide (A-5) isophthalic acid 45 mol%, terephthalic acid 5 mol%, hexamethylenediamine 45 mol%, bis-(4-amino- 10 kg of raw materials with a ratio of 5 mol % of 3-methylcyclohexyl)methane were charged into the reaction tank together with 8 kg of pure water, and the air in the reaction tank was degassed several times with nitrogen. After raising the temperature to 90°C and reacting for 5 hours, the reaction temperature was gradually raised to 280°C over 10 hours while stirring the tank under pressure (18 watts). Then, after the pressure was released to lower the pressure to atmospheric pressure, polymerization was further performed at the same temperature for 6 hours. After the reaction, it was taken out from the reaction tank and cut to obtain pellets. The relative viscosity of the obtained pellets (by the same method as above) was 1.90. The glass transition temperature is 150°C, and the crystal fusion heat is 0 cal / g. This amorphous...

reference example 2

[0061] (Reference example 2): Amorphous polyamide (A-6) 10 kg and 8 kg of raw materials in the ratio of 70 mol % of isophthalic acid, 30 mol % of terephthalic acid, and 100 mol % of hexamethylenediamine Pure water is put into the reaction tank together, and the air in the reaction tank is degassed several times with nitrogen. After raising the temperature to 90°C and reacting for 5 hours, the reaction temperature was gradually raised to 280°C over 10 hours while stirring the tank under pressure (18 watts). Then, after the pressure was released to lower the pressure to atmospheric pressure, polymerization was further performed at the same temperature for 6 hours. After the reaction was completed, it was taken out from the reaction tank and cut to obtain pellets. The relative viscosity of the obtained pellets (by the same method as above) was 2.1. The glass transition temperature is 125°C, and the crystal fusion heat is 0 cal / g.

[0062] (1) Raw material (A) polyamide resin, ...

manufacture example

[0069] (Manufacturing example) (A-7) Preparation of polyamide resin Using TEM37BS manufactured by Toshiba Machine Co., Ltd., 40% by mass of polyamide 66 resin, 40% by mass of polyamide 66 resin, The polyamide 12 resin is 25% by mass, and the amorphous polyamide resin is 35% by mass. The obtained polyamide resin (A-7) was dried and used for later tests.

[0070] (A-8) to (A-17) Polyamide resins were prepared in the same manner as (A-7) according to the compounding ratio described in Table 1.

[0071] (A-18) to (A-27) Polyamide resins were prepared in the same manner as (A-7) according to the compounding ratio described in Table 2.

[0072] 【Table 2】

[0073] (A-28)-(A-35) Polyamide resins were prepared in the same manner as (A-7) according to the compounding ratio described in Table 3.

[0074] 【table 3】

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com