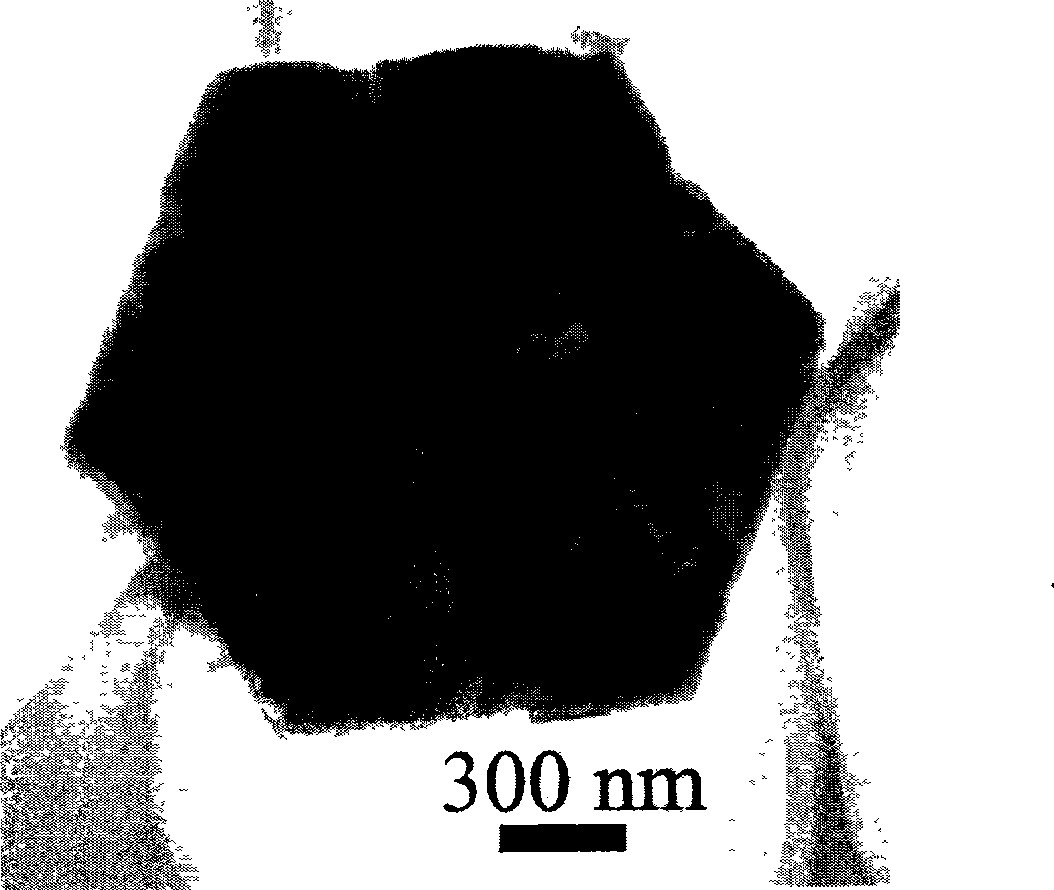

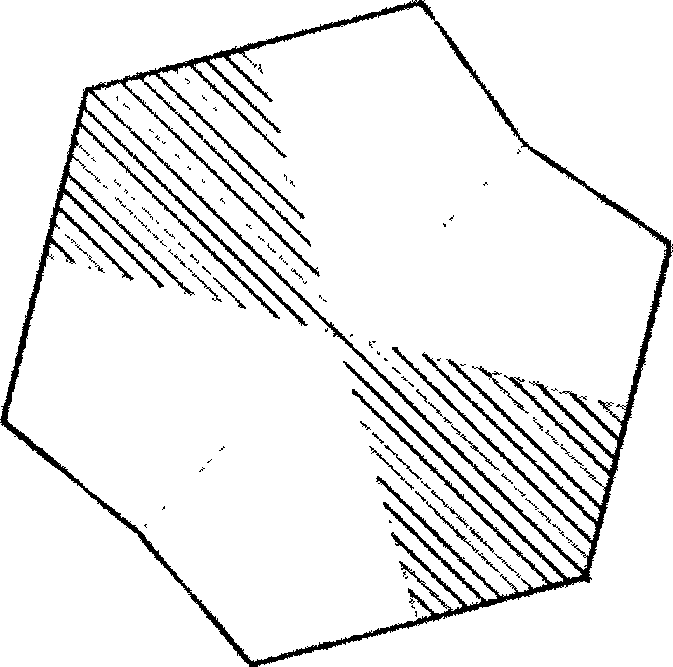

Quasi-hexagonal sheet calcium carbonate metastable-state crystal particle and method of preparing the same

A hexagonal flaky, calcium carbonate technology, applied in the direction of calcium carbonate/strontium/barium, inorganic compound addition, etc., can solve the problem of no pseudo-hexagonal flaky calcium carbonate particles, etc., to achieve saving pulp consumption, good coating ability and covering ability, good optical properties and the effect of printing properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of calcium lauryl sulfate: Dissolve 34g of calcium chloride in 200ml of deionized water, dissolve 100g of sodium lauryl sulfate in 800ml of deionized water, heat to above 60°C respectively, mix, gradually cool, wash, and filter , the product was recrystallized (dissolved above 60°C, cooled at room temperature, filtered), and vacuum-dried at 40°C.

[0026] Preparation of calcium carbonate particles: 50g containing 2.0wt% calcium lauryl sulfate, 1.5wt% n-amyl alcohol and an aqueous solution of a certain amount of ammonia, so that [NH 3 ]:[Ca 2+ ]=4:1. Pass CO into the solution at a rate of 2.5ml / min 2 Gas for 1 hour, stirring constantly during aeration, aging for 24 hours. The product was filtered, washed, and dried at room temperature for 24 hours. That is, pseudo-hexagonal flaky calcium carbonate metastable crystal (aragonite) particles are obtained.

Embodiment 2

[0028] Preparation of calcium dodecylsulfonate: Dissolve 34g of calcium chloride in 200ml of deionized water, dissolve 100g of sodium dodecylsulfonate in 800ml of deionized water, heat to above 60°C, mix, gradually cool, and wash , filtered, and the product was recrystallized (dissolved above 60°C, cooled at room temperature, filtered), and vacuum-dried at 40°C.

[0029] Preparation of calcium carbonate particles: 50g containing 2.0wt% calcium dodecylsulfonate, 1.5wt% n-butanol and an aqueous solution of a certain amount of ammonia, so that [NH 3 ]: [Ca 2+ ]=4:1. Pass CO into the solution at a rate of 2.5ml / min 2 Gas for 1 hour, stirring constantly during aeration, aging for 24 hours. The product was filtered, washed, and dried at room temperature for 24 hours. That is, pseudo-hexagonal flaky calcium carbonate metastable crystal (aragonite) particles are obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com