Production method of plywood for container bottom board

The technology of a container bottom plate and a manufacturing method is applied in the joining of wooden veneers, chemical instruments and methods, machine tools suitable for grinding workpiece planes, etc. and other problems, to achieve the effect of no foaming on the surface, wide application range and long life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

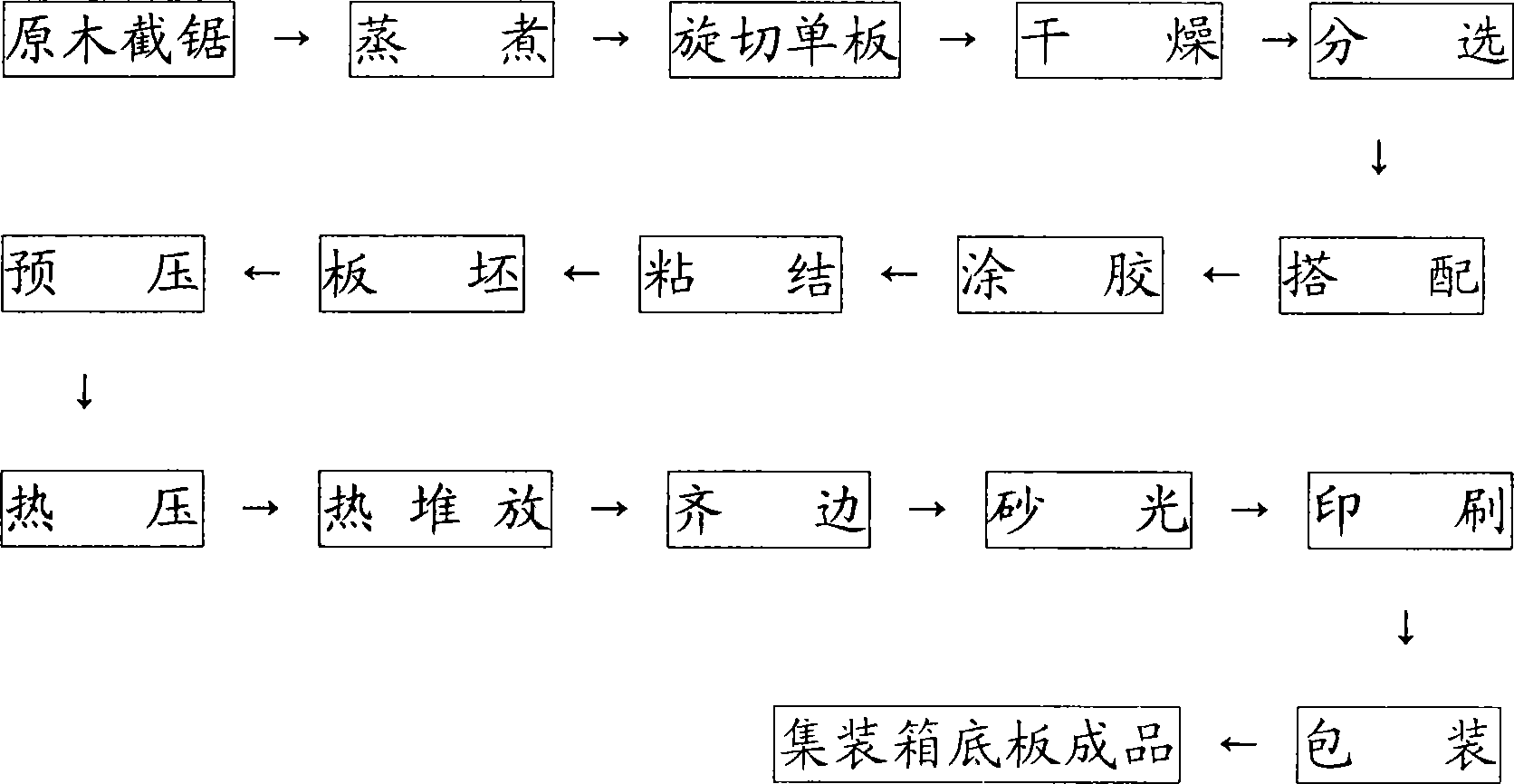

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings. As attached to the manual figure 1 , 2 , as shown in 3:

[0025] A method for making plywood for container bottom plates, the operation steps are sawing logs, cooking, rotary cutting veneers, drying, sorting, matching, gluing, bonding, slabs, pre-pressing, hot pressing, hot stacking, Edge trimming, sanding, printing, and packaging to make finished container bottom plates;

[0026] The log is selected from Abidon wood, imported hard miscellaneous wood, white eucalyptus, and domestic hard miscellaneous wood in a permutation and combination manner, or Abidon wood, imported hard miscellaneous wood, white eucalyptus A kind of wood, domestic hard miscellaneous wood;

[0027] The rotary-cut veneer is a long medium plate and a short medium plate of a rotary cut plate structure, the long medium plate is a plate structure with a forward direction of the grain, and the short ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com