Mineral separation process capable of recovering micro scheelite from scheelite flotation tailings

A technology of flotation tailings and ore dressing method, which is applied in the application field of secondary utilization of mineral resources, can solve the problems that the comprehensive utilization rate of tungsten resources is less than 60%, easy to be crushed, and easy to muddy, etc., so as to improve the total recovery of ore dressing High efficiency, small dosage of chemicals, and environment-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

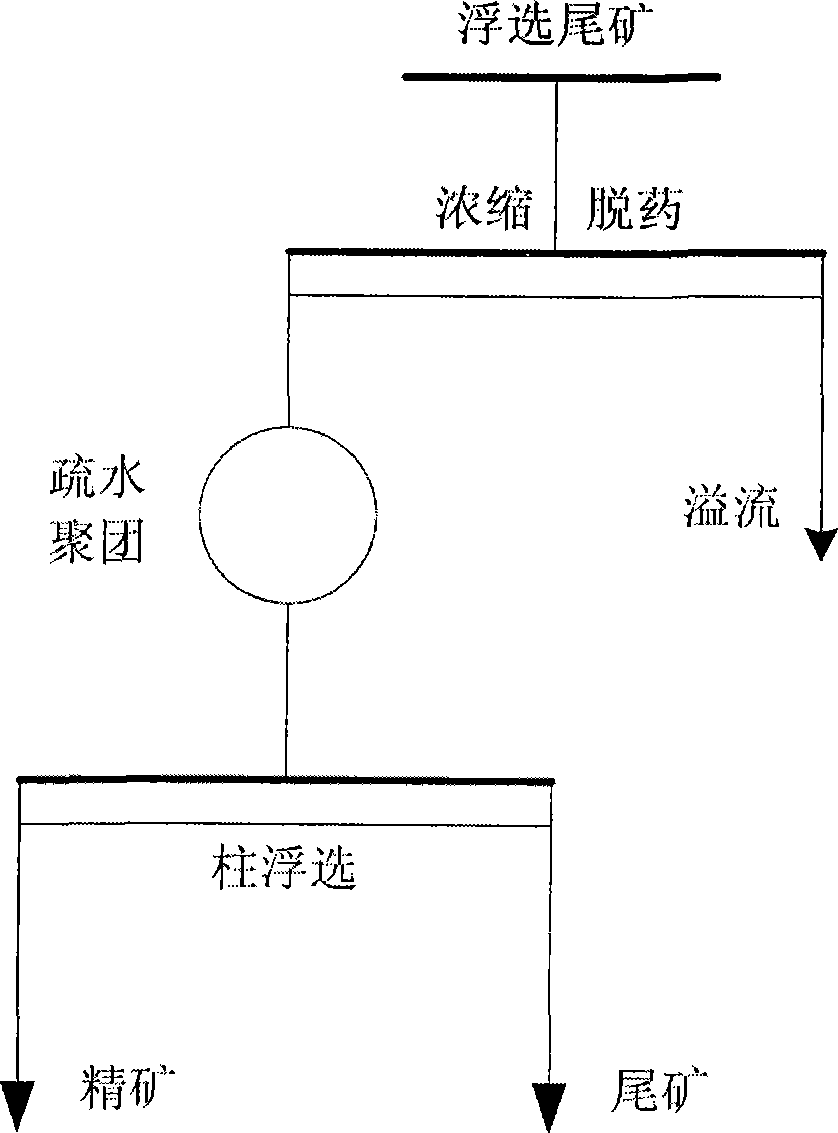

Method used

Image

Examples

Embodiment 1

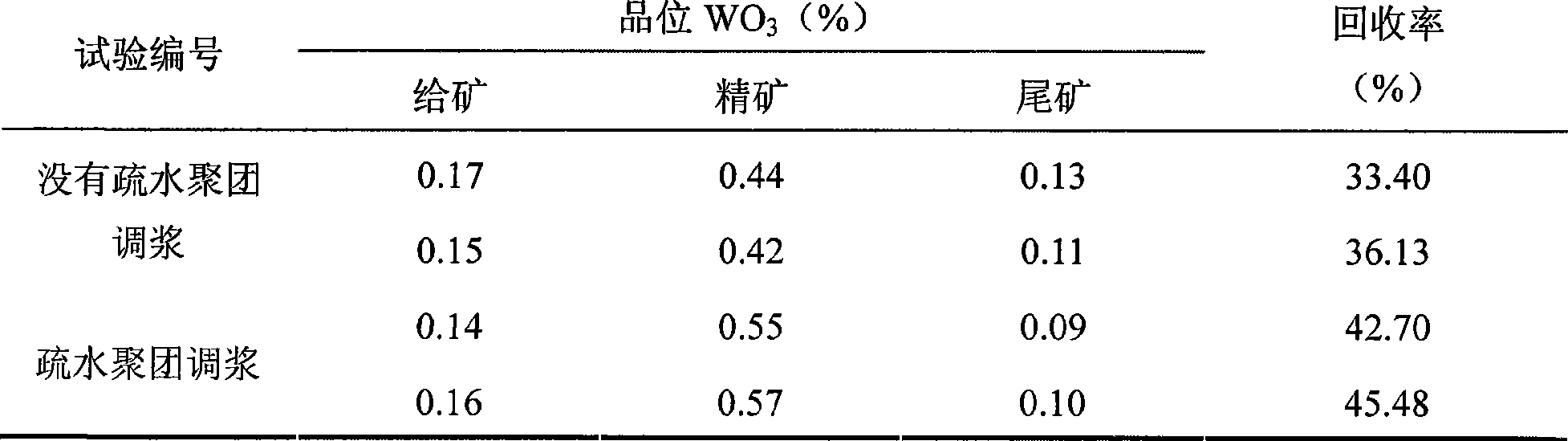

[0025] Example 1: After the tailings are settled, deslimed, and drug removed, 200 g / ton of sodium carbonate is added to adjust the pH value of the pulp to 9-10, 600 g / ton of water glass is added, and 100 g / ton of saponified oleic acid is added to hydrophobic After column flotation after pulping, the flotation tailing column flotation test of conventional flotation pulping (the type and amount of added reagents are the same as hydrophobic pulping, using conventional pulping) was carried out at the same time. The test results are shown in Table 1 , From the test results, it can be known that the flotation of the hydrophobic agglomeration slurry column is better than the test index of the conventional flotation slurry column flotation.

[0026] Table 1 The test results of flotation treatment of scheelite roughing tailings by adding saponified oleic acid hydrophobic agglomeration slurry and conventional flotation slurry column flotation

[0027]

Embodiment 2

[0028] Embodiment two: After the tailings are settled, deslimed, and drug removed, 200 grams / ton of sodium carbonate is added to adjust the pH value of the pulp to 9 to 10, 600 grams / ton of water glass is added, and 75 grams / ton of saponified oleic acid and Oxidized paraffin wax soap 731 (25 g / t) was used for hydrophobizing after column flotation, and the flotation tailings column flotation test was carried out at the same time as conventional flotation slurry (the type of agent is the same as the amount of hydrophobic slurry, and conventional slurry is used) , The test results are shown in Table 2. From the test results, it can be seen that the flotation of the hydrophobic agglomeration slurry column is better than the test index of the conventional flotation slurry column flotation.

[0029] Table 2 The test results of adding saponified oleic acid and 731 hydrophobic agglomeration sizing and conventional flotation sizing column flotation treatment of scheelite roughing tailin...

Embodiment 3

[0031] Embodiment three: After the tailings are settled, deslimed, and drug removed, 200 grams / ton of sodium carbonate is added to adjust the pH value of the slurry to 9 to 10, 600 grams / ton of water glass is added, and 75 grams / ton of saponified oleic acid and Oxidized paraffin wax soap 733 (25 g / t) was used for hydrophobic sizing after column flotation, and conventional flotation sizing (the type and quantity of reagents are the same as for hydrophobic sizing, and conventional sizing was used) for flotation tailings column flotation Test, the test results are shown in Table 3. From the test results, it can be seen that the flotation of the hydrophobic agglomeration slurry column is better than the test index of the conventional flotation slurry column flotation.

[0032] Table 3 The test results of adding saponified oleic acid and 733 hydrophobic agglomeration slurry and conventional flotation slurry column flotation to treat scheelite roughing tailings

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com