Fluorocarbon gemini surfactant as well as preparation method and application thereof

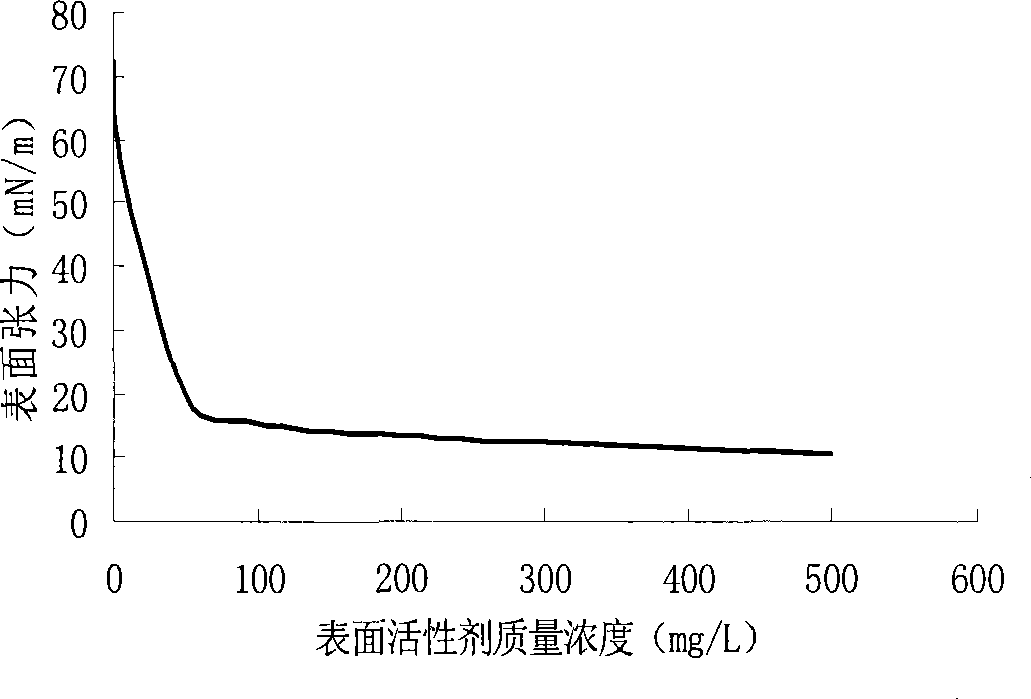

A Gemini surfactant and active agent technology, which is applied in the field of fluorocarbon Gemini surfactant and its preparation, can solve the problems of high concentration of surfactants, poor compatibility of polymers, poor temperature and salt resistance of surfactants, etc., and achieve Ease of handling, small change in performance, effect of reducing surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1, preparation fluorocarbon gemini surfactant

[0034] 1) Dissolve 100.4g (0.2mol) perfluorooctanesulfonyl fluoride in ethyl acetate, mix with 5.92g (0.08mol) 1,3-propanediamine, heat to 70°C, then add 1.12g ( 0.02mol) Potassium hydroxide was reacted under stirring conditions for 8 hours; after drying, the dried product was mixed with an aqueous solution of sodium hydroxide with a concentration of 1.0% by mass, the organic matter was extracted, and the brown solid obtained after removing water was bis-perfluorooctyl Sulfonamide.

[0035] 2) Mix 103.8g (0.1mol) bis-perfluorooctane sulfonamide and 16.1g (0.2mol) 2-chloroethanol in ethanol solution, then add 0.56g (0.01mol) potassium hydroxide, and stir at 80°C Carrying out the reaction for 8 hours to obtain N-N-ethanol bis perfluorooctane sulfonamide;

[0036] 3) Mix 112.6g (0.1mol) of N-N-ethanol bisperfluorooctane sulfonamide with 6.8g (0.2mol) of hydrogen peroxide, then add 0.56g (0.01mol) of potassium hyd...

Embodiment 2

[0041] Embodiment 2, preparation fluorocarbon gemini surfactant

[0042] 1) Dissolve 125.5g (0.25mol) perfluorooctanesulfonyl fluoride in ethyl acetate, mix with 0.08mol ethylenediamine, heat to 80°C, then add 1.40g (0.025mol) potassium hydroxide and stir The reaction was carried out under the conditions for 8 hours; after drying, the dried product was mixed with an aqueous sodium hydroxide solution with a concentration of 1.0% by mass to extract organic matter, and after removing water, a tan solid was obtained as bis-perfluorooctane sulfonamide.

[0043] 2) Mix 103.8g (0.1mol) bis-perfluorooctane sulfonamide and 20.125g (0.25mol) 2-chloroethanol in ethanol solution, then add 1.40g (0.025mol) potassium hydroxide, and stir at 70°C The reaction was carried out for 6 hours to obtain N-N-ethanol bis-perfluorooctanesulfonamide;

[0044] 3) Mix 112.6g (0.1mol) of N-N-ethanol bisperfluorooctane sulfonamide with 8.5g (0.25mol) of hydrogen peroxide, then add 1.40g (0.025mol) of potassi...

Embodiment 3

[0046] Embodiment 3, preparation fluorocarbon gemini surfactant

[0047] 1) Dissolve 100.4g (0.2mol) of perfluorooctanesulfonyl fluoride in ethyl acetate, mix with 0.1mol of 1,4-butylene diamine, heat to 70°C, then add 0.56g (0.01mol) of hydroxide Potassium was reacted under stirring conditions for 6 hours; after drying, the dried product was mixed with an aqueous solution of sodium hydroxide with a concentration of 0.8% by mass to extract organic matter, and after removing water, a tan solid was obtained as bis-perfluorooctane sulfonamide.

[0048] 2) Mix 103.8g (0.1mol) bis-perfluorooctane sulfonamide and 16.1g (0.20mol) 2-chloroethanol in ethanol solution, then add 0.56g (0.01mol) potassium hydroxide, and stir at 80°C Carrying out the reaction for 8 hours to obtain N-N-ethanol bis perfluorooctane sulfonamide;

[0049] 3) Mix 112.6g (0.1mol) of N-N-ethanol bisperfluorooctane sulfonamide with 8.5g (0.25mol) of hydrogen peroxide, then add 1.40g (0.025mol) of potassium hydroxi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com