Method for implementing image transfer on semiconductor material by anodised aluminum template

An anodized aluminum, pattern transfer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of low order and uniformity, inability to obtain high-performance devices, high process and equipment requirements, etc. Achieve the effects of simple production process and process, low preparation cost and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

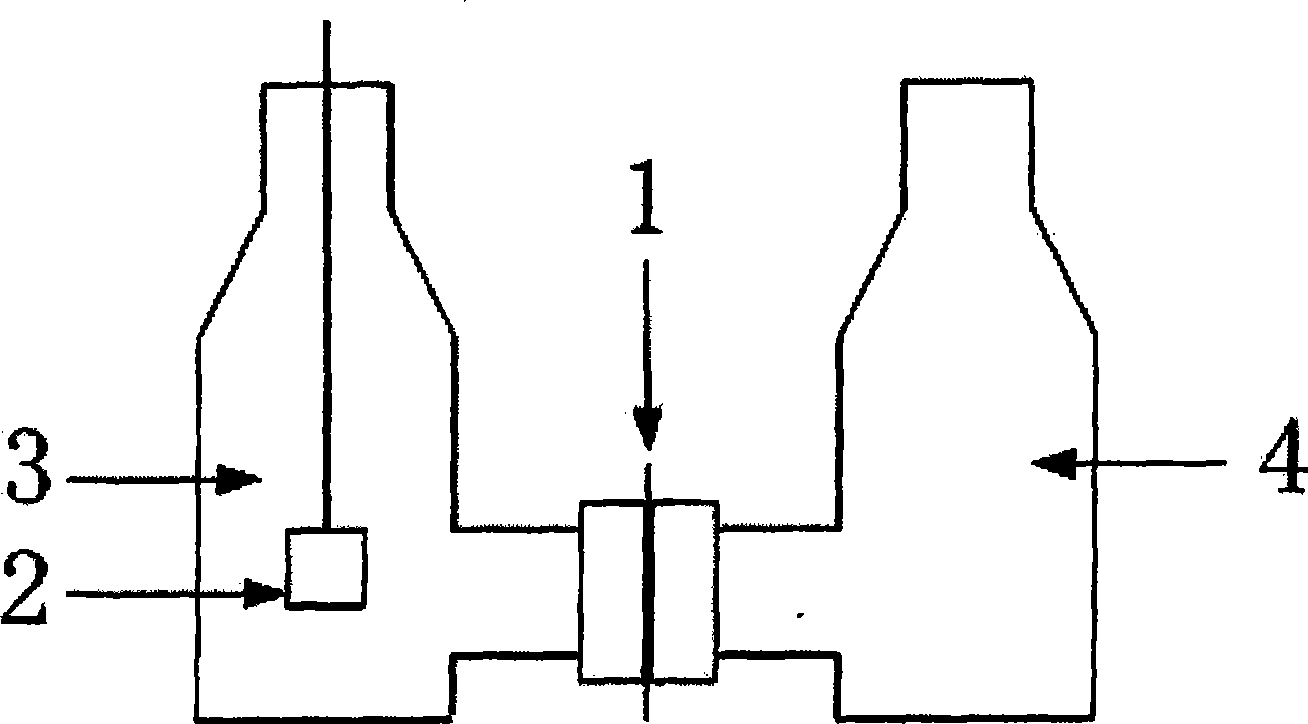

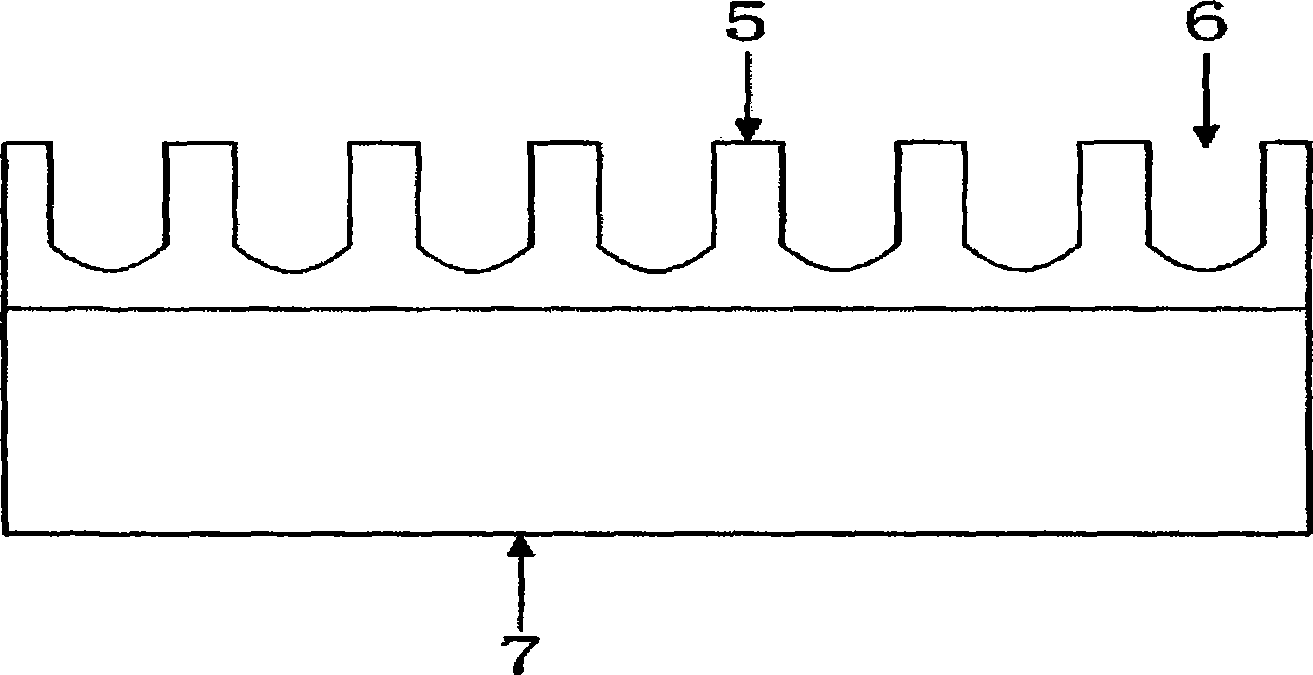

[0041] see figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 In combination with specific examples, the process of utilizing the prepared anodized aluminum template to realize pattern transfer of small hole arrays on semiconductor materials will be further described in detail. Specifically include the following steps:

[0042] Step 1: Take an aluminum sheet 1, clean and polish;

[0043] Take an aluminum sheet 1 with a thickness of 100-500 microns and a purity of 99.99%. First soak in acetone for 1-5 hours to remove the oil on the surface of the aluminum sheet 1, then soak in a sodium hydroxide solution with a mass fraction of 4-6% at 60 degrees Celsius for 60-90 seconds to remove the natural oxidation on the surface of the aluminum sheet 1 After rinsing the membrane with deionized water, soak the aluminum sheet 1 in 300-400 g / L nitric acid solution for 3-5 minutes to remove the alkali film formed on the surface, and then rinse it with deionized water.

[0044]T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com