Seepage deformation test method for hydropower station dam coastal construction soft rock zone

A technology of seepage deformation and test method, which is applied in the field of seepage deformation test of the weak rock belt along the coast of the dam body of a hydropower station, can solve problems such as affecting the benefit of power generation, endangering the safety of the dam body, and unsatisfactory results, so as to increase the pressure value and improve The effect of hydraulic ramping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

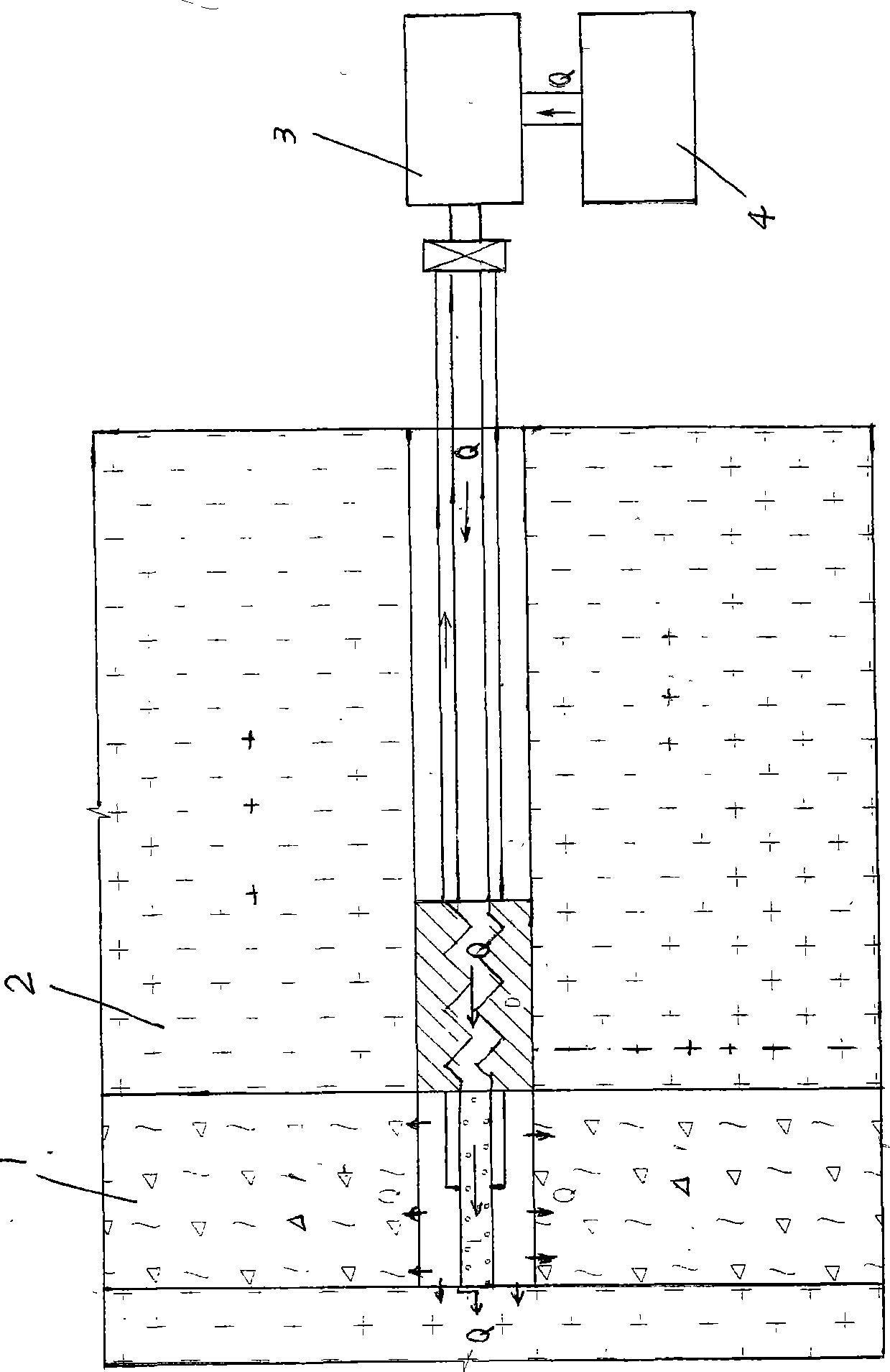

[0010] Example: The seepage deformation test of the structurally weak rock belt on the right bank of the Nuozhadu Hydropower Station on the Lancang River in Yunnan, combined with the exposure of the dam foundation exploration adit on the right bank of the project, selected the dam body fault F 12 , F 13 (dam fault number) Exploration adits with better outlets and highly representative components are tested, and multiple sets of experiments are carried out.

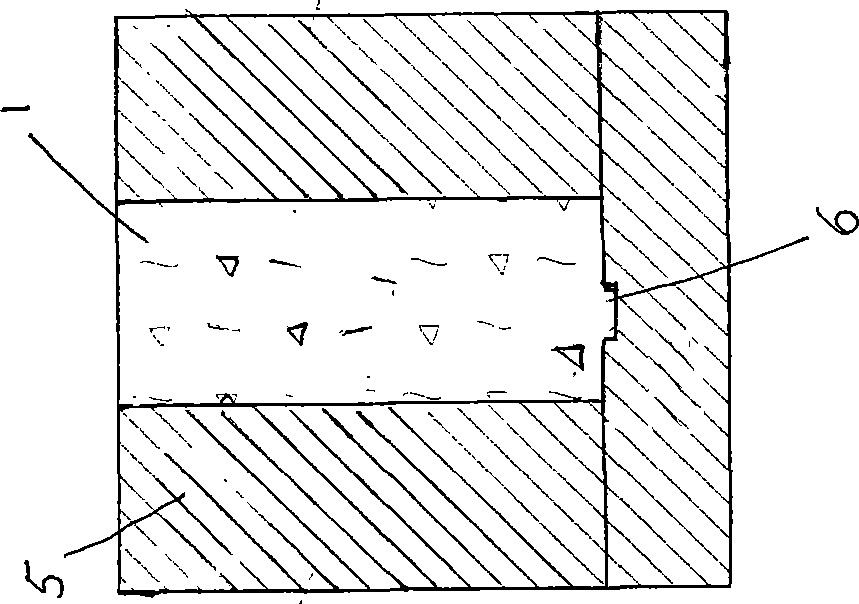

[0011] Firstly, expand the adit about 15m within the position where the fault is exposed in the adit, so as to be able to install boreholes, pressurized water tests and personnel activities. Then drill holes in the direction perpendicular to the fault. The depth of the drill hole exposes the fault and its affected zone, and uses an extended plug to isolate the test hole section in the upper part of the fault affected zone. Finally, the water pressure test is carried out, and the GJY-IV type grouting automatic recorder is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com