A kind of method for preparing anilinoacetonitrile

A technology of anilinoacetonitrile and hydroxyacetonitrile, which is applied in the preparation of carboxylic acid nitrile, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of limiting the use of microchannel reactors and large equipment corrosion, and avoid decomposition or polymerization. phenomenon, fast response, and the effect of improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

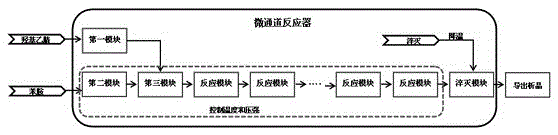

Image

Examples

Embodiment 1

[0043] 1) Use a 30% sodium hydroxide solution to adjust the pH of the hydroxyacetonitrile solution with a mass percentage of 10.0% to 2.5, and then pass it into the G1R*F module through a metering pump;

[0044] 2) Pass aniline with a mass percentage of 99.0% into the G1SHH module for preheating, and the preheating temperature is 130°C;

[0045] 3) Synchronously pump the hydroxyacetonitrile treated in step 1) at a volume flow rate of 35mL / min and the aniline preheated in step 2) at a volume flow rate of 5mL / min into the G1SHH module for mixing, and the temperature of the module is 130°C ;

[0046] 4) The mixed material liquid obtained in step 3) continues to pass through 8 G1SHH modules connected in series, the module temperature is 130°C, and the pressure is 0.3MPa;

[0047] 5) Introduce the feed liquid after step 4) into the G1SHF module to quench the reaction at 70°C;

[0048]6) The material liquid obtained in step 5) was exported, and the material receiving time was 35 m...

Embodiment 2

[0050] 1) Take a hydroxyacetonitrile solution with a mass percentage of 10.0%, and its pH is 1.5, and pass it into the G1SHH module through a metering pump;

[0051] 2) Pass aniline with a mass percentage of 99.14% into the G1R*F module for preheating, and the preheating temperature is 130°C;

[0052] 3) Synchronously pump the hydroxyacetonitrile treated in step 1) at a volume flow rate of 35mL / min and the aniline preheated in step 2) at a volume flow rate of 5mL / min into the G1SHH module for mixing, and the temperature of the module is 130°C ;

[0053] 4) The mixed material liquid obtained in step 3) continues to pass through 12 G1R*H modules connected in series, the module temperature is 130°C, and the pressure is 0.35MPa;

[0054] 5) Introduce the feed liquid after step 4) into the G1SHF module to quench the reaction at 60°C;

[0055] 6) The material liquid obtained in step 5) was exported, and the receiving time was 45 minutes. The temperature in the reaction bottle was ...

Embodiment 3

[0057] 1) Use a 10% sodium hydroxide solution to adjust the pH of the hydroxyacetonitrile solution with a mass percentage of 20.0% to 3.0, and then pass it into the G1R*F module through a metering pump;

[0058] 2) Pass aniline with a mass percentage of 99.25% into the G1R*F module for preheating, and the preheating temperature is 135°C;

[0059] 3) Synchronously pump the hydroxyacetonitrile treated in step 1) at a volume flow rate of 30mL / min and the aniline preheated in step 2) at a volume flow rate of 10mL / min into the G1SHH module for mixing, and the temperature of the module is 135°C ;

[0060] 4) The mixed material liquid obtained in step 3) continues to pass through 5 series-connected G1SHH modules and 5 series-connected G1R*H modules. The temperature of the modules is 135°C and the pressure is 0.44MPa;

[0061] 5) Introduce the feed liquid after step 4) into the G1SHF module to quench the reaction at 65°C;

[0062] 6) The feed liquid obtained in step 5) was exported,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volumetric flow rate | aaaaa | aaaaa |

| volumetric flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com