Soldering flux and soldering paste

A technology of flux and solder paste, used in welding media, welding equipment, welding/cutting media/materials, etc., and can solve problems that have not been specifically researched

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

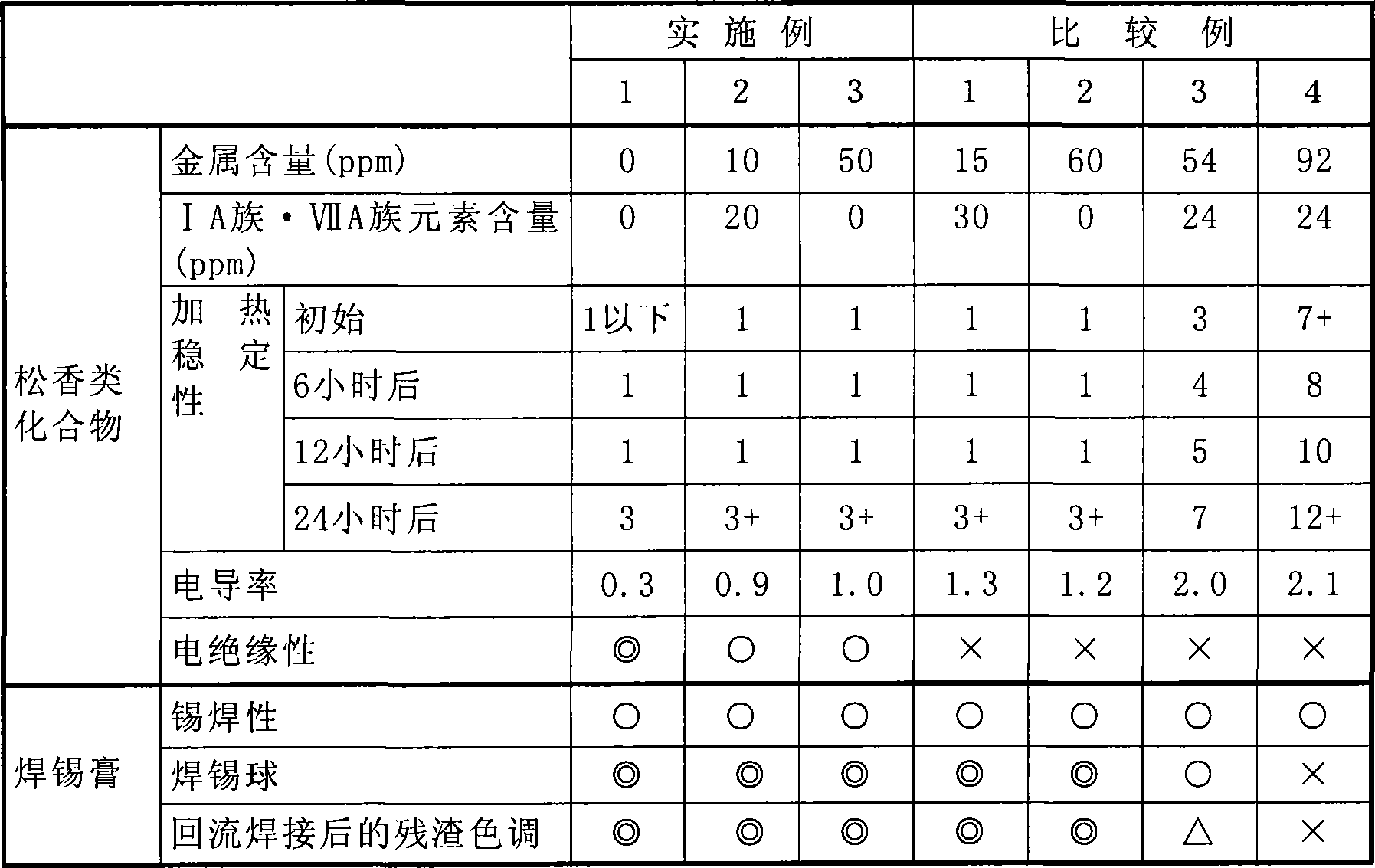

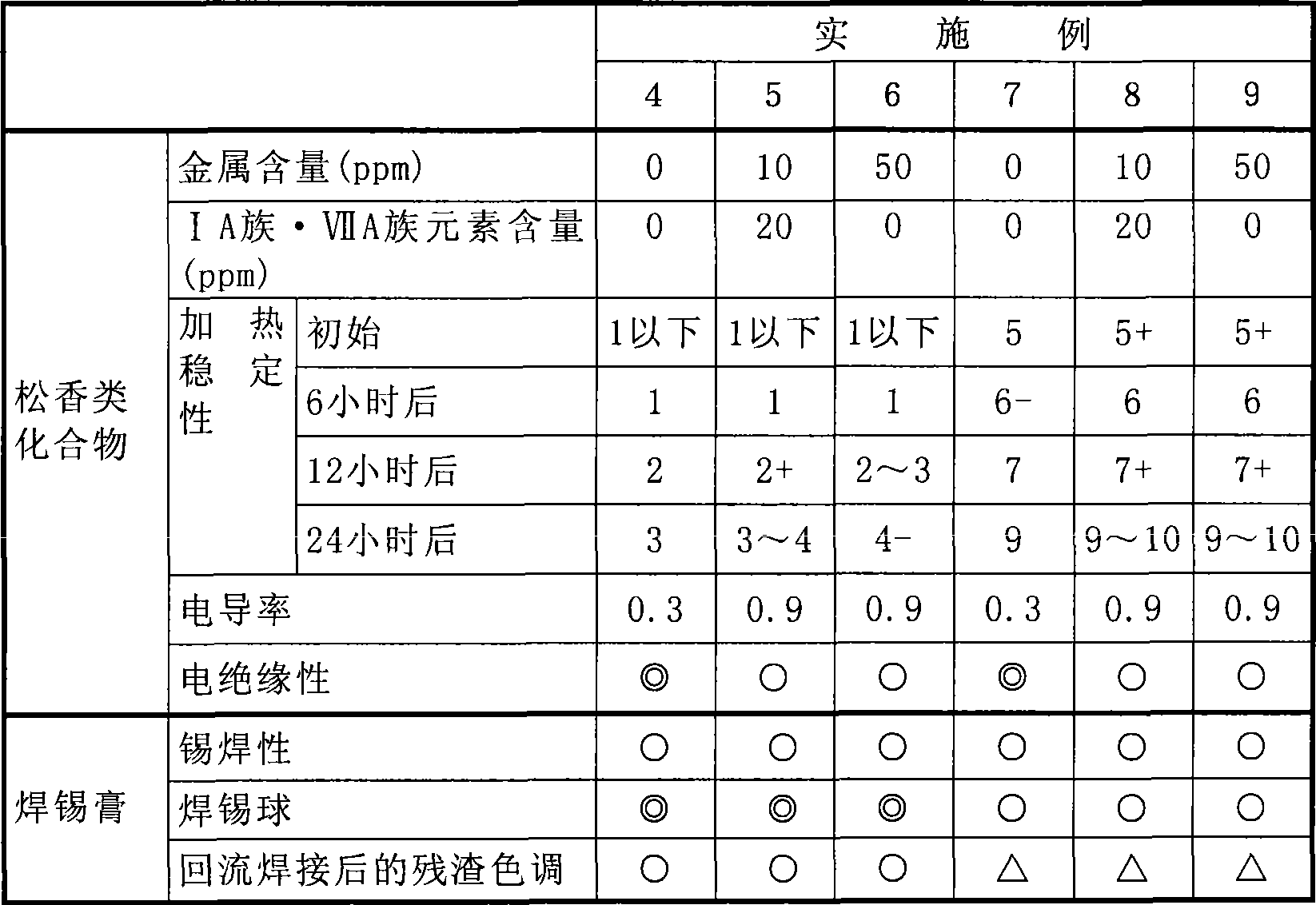

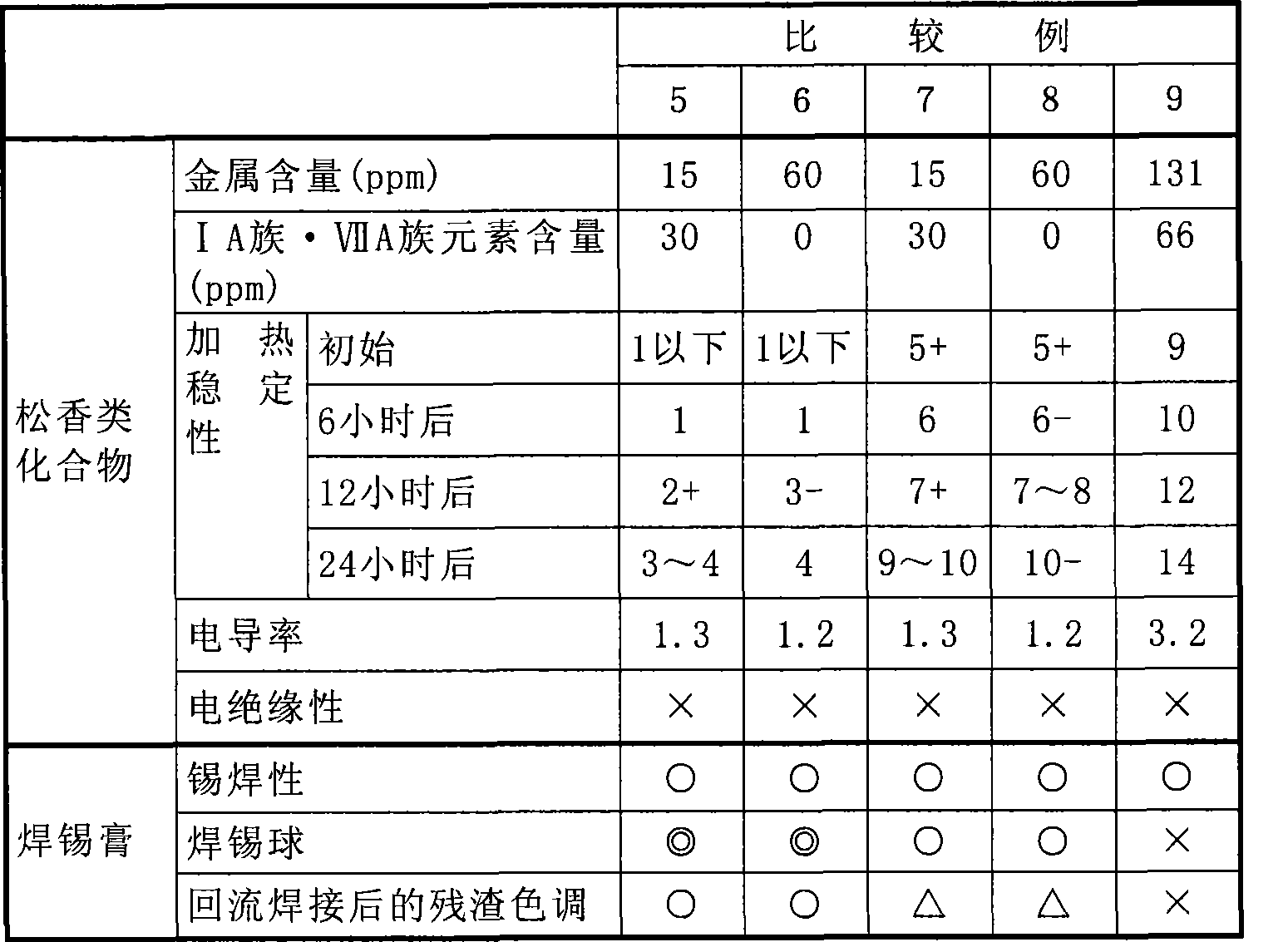

Examples

Embodiment 1

[0074] (1) Refining process of raw material rosin

[0075] Put 1,000g of unrefined Chinese gum rosin with an acid value of 170mgKOH / g, a softening point of 74°C, and a Gardner color of 6, and 500g of xylene into the flask, heat and dissolve it, distill off about 350g of xylene, and then add 350g cyclohexane, cooled to room temperature. After cooling to generate about 100 g of crystals, the supernatant was transferred to another flask, and then recrystallized at room temperature, then the supernatant was removed, washed with 100 g of cyclohexane, and the solvent was distilled off to obtain 700 g of refined rosin .

[0076] (2) Addition reaction process

[0077]660 g of the purified rosin obtained in (1) above and 100 g of acrylic acid were added to a reaction vessel, and the reaction was carried out at 220° C. for 4 hours while stirring under nitrogen flow, and then the unreacted substances were removed under reduced pressure to obtain 720 g of acrylic acid. into a reaction ...

Embodiment 2

[0087] (1) Add 100g of the refined colorless rosin compound obtained in Example 1(4) and 1g of 1000ppm sodium chloride aqueous solution into the flask, and remelt it to obtain an acid value of 245.8mgKOH / g, a softening point of 132.0°C, and a Gard A refined colorless rosin compound with a Nachroma of 1. The metal content in the refined colorless rosin compound is 10 ppm, and the content of group IA elements and group VIIA elements is 20 ppm.

[0088] (2) Preparation of flux and solder paste

[0089] Except having used 50 parts by weight of the purified colorless rosin-based compound obtained in (1) above, it carried out similarly to Example 1 (5) and (6), and produced the flux and solder paste of this invention.

Embodiment 3

[0091] (1) the refined colorless rosin compound obtained in 100g embodiment 1 (4), 7.2mg iron oxide (Fe 2 o 3 ) into a flask and remelted to obtain a refined colorless rosin compound having an acid value of 245.8 mgKOH / g, a softening point of 132.0° C., and a Gardner color of 1. The metal content in the refined colorless rosin compound is 50 ppm, and the content of group IA elements and group VIIA elements is 0 ppm.

[0092] (2) Preparation of flux and solder paste

[0093] Except having used 50 parts by weight of the purified colorless rosin-based compound obtained in (1) above, it carried out similarly to Example 1 (5) and (6), and produced the flux and solder paste of this invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com