Decoloring agent for reducing anisidine value of soya-bean oil for injection and preparation method thereof

A technology of soybean oil and anisidine value for injection, which is applied in the direction of fat oil/fat refining, chemical instruments and methods, and other chemical processes. The effect of hydrophobicity and strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

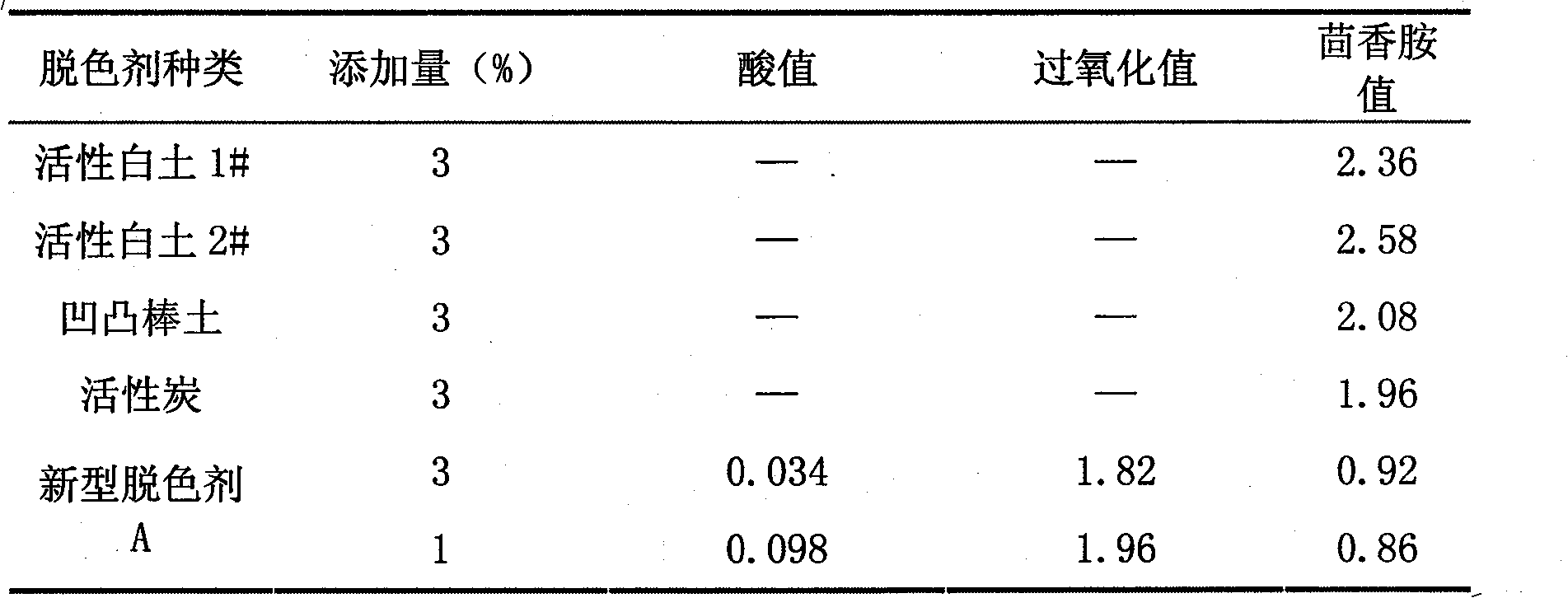

Image

Examples

example 1

[0016] Example 1: The preparation method of decolorizing agent comprises the following steps: (1) attapulgite purification: at first attapulgite clay is added according to mass ratio 5: 3, stirs in distilled water, mass concentration 5% sulfuric acid and wet attapulgite are by mass The volume ratio is 1:3 and soaked for 1 hour; secondly, the mass concentration of 30% sodium hexametaphosphate aqueous solution is added into the attapulgite solution according to the volume ratio of 3:1, the mass concentration of 1% NaOH solution is adjusted to pH 7, and ultrasonic vibration is performed for 1.5 hours; Then static sedimentation, separation of deposition impurity layer to obtain a suspension, the suspension is press-filtered in a filter press to obtain attapulgite with a water content of 40%; finally dry at a temperature of 200° C. for 3 hours in a drying oven to obtain a purified attapulgite; (2) attapulgite Attapulgite activation: Purified attapulgite is roasted at 350°C for 3 hou...

example 2

[0023] Example 2: the preparation method of decolorizing agent comprises the following steps: (1) attapulgite purification: first attapulgite clay is added according to mass ratio 5: 3, stirs in distilled water, mass concentration 5% sulfuric acid and wet attapulgite are by mass The volume ratio is 1:3 and soaked for 1 hour; secondly, the mass concentration of 30% sodium hexametaphosphate aqueous solution is added into the attapulgite solution according to the volume ratio of 3:1, the mass concentration of 1% NaOH solution is adjusted to pH 7, and ultrasonic vibration is performed for 1.5 hours; Then static sedimentation, separation of deposition impurity layer to obtain a suspension, the suspension is press-filtered in a filter press to obtain attapulgite with a water content of 40%; finally dry at a temperature of 200° C. for 3 hours in a drying oven to obtain a purified attapulgite; (2) attapulgite Attapulgite activation: Purified attapulgite is roasted at 425°C for 2 hours ...

example 3

[0024] Example 3: the preparation method of decolorizing agent comprises the following steps: (1) attapulgite purification: first attapulgite clay is added according to mass ratio 5: 3, stirs in distilled water, mass concentration 5% sulfuric acid and wet attapulgite are by mass The volume ratio is 1:3 and soaked for 1 hour; secondly, the mass concentration of 30% sodium hexametaphosphate aqueous solution is added into the attapulgite solution according to the volume ratio of 3:1, the mass concentration of 1% NaOH solution is adjusted to pH 7, and ultrasonic vibration is performed for 1.5 hours; Then static sedimentation, separation of deposition impurity layer to obtain a suspension, the suspension is press-filtered in a filter press to obtain attapulgite with a water content of 40%; finally dry at a temperature of 200° C. for 3 hours in a drying oven to obtain a purified attapulgite; (2) attapulgite Attapulgite activation: Purified attapulgite is roasted at 500°C for 1 hour t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com