Decoloring agent for reducing anisidine value of soya-bean oil for injection and preparation method thereof

A technology of soybean oil for injection and anisidine value, which is applied in the directions of fat oil/fat refining, chemical instruments and methods, other chemical processes, etc., can solve the problems of reduction, the inability to achieve predetermined values of decolorizing agent activated carbon, etc., and achieves simple process and improved The effect of hydrophobicity and strong pigment ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

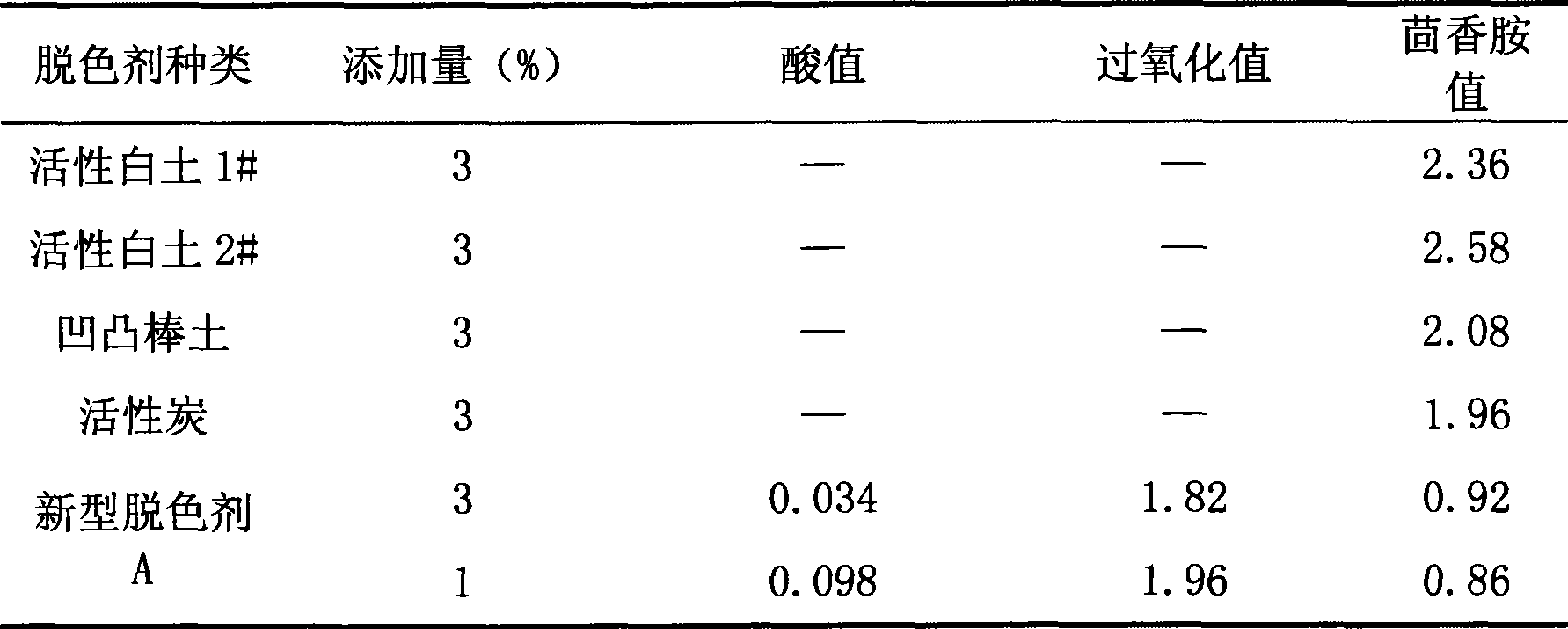

Problems solved by technology

Method used

Image

Examples

example 1

[0015] Example 1: The preparation method of the decolorizing agent comprises the following steps: (1) attapulgite purification: at first attapulgite clay is added according to mass ratio 5:3, stirs in distilled water, mass concentration 5% sulfuric acid and wet attapulgite by mass volume The ratio is 1:3 and soaked for 1 hour; secondly, the mass concentration of 30% sodium hexametaphosphate aqueous solution is added into the attapulgite solution according to the volume ratio of 3:1, and the mass concentration of 1% NaOH solution is adjusted to a pH value of 7, and ultrasonic vibration is performed for 1.5 hours; then Static sedimentation, separation of deposited impurity layer to obtain a suspension, the suspension is press-filtered in a filter press to obtain attapulgite with a water content of 40%; finally, dry attapulgite at a temperature of 200°C for 3 hours in a drying oven to obtain purified attapulgite; (2) attapulgite Soil activation: the purified attapulgite is roasted...

example 2

[0022] Example 2: The preparation method of the decolorizing agent comprises the following steps: (1) attapulgite purification: at first the attapulgite clay is added according to the mass ratio of 5:3, stirred evenly in distilled water, mass concentration 5% sulfuric acid and wet attapulgite according to mass volume The ratio is 1:3 and soaked for 1 hour; secondly, the mass concentration of 30% sodium hexametaphosphate aqueous solution is added into the attapulgite solution according to the volume ratio of 3:1, and the mass concentration of 1% NaOH solution is adjusted to a pH value of 7, and ultrasonic vibration is performed for 1.5 hours; then Static sedimentation, separation of deposited impurity layer to obtain a suspension, the suspension is press-filtered in a filter press to obtain attapulgite with a water content of 40%; finally, dry attapulgite at a temperature of 200°C for 3 hours in a drying oven to obtain purified attapulgite; (2) attapulgite Soil activation: the p...

example 3

[0023] Example 3: The preparation method of the decolorizing agent comprises the following steps: (1) Attapulgite purification: first attapulgite clay is added according to the mass ratio of 5:3, stirred evenly in distilled water, mass concentration 5% sulfuric acid and wet attapulgite according to mass volume The ratio is 1:3, add soaking for 1h; secondly, the mass concentration of 30% sodium hexametaphosphate aqueous solution is added into the attapulgite solution according to the volume ratio of 3:1, the mass concentration is 1% NaOH solution to adjust the pH value to 7, ultrasonic vibration for 1.5h; then Static sedimentation, separation of deposited impurity layer to obtain a suspension, the suspension is press-filtered in a filter press to obtain attapulgite with a water content of 40%; finally, dry attapulgite at a temperature of 200°C for 3 hours in a drying oven to obtain purified attapulgite; (2) attapulgite Soil activation: the purified attapulgite is roasted at 500°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com