Iron based amorphous nanocrystalline composite coating

An iron-based amorphous and nanocrystalline technology, which can be used in coatings, metal material coating processes, melting spray plating, etc., and can solve the problems of high cost and limited application and promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the iron-based thermal spraying drug core wire can adopt the method of the prior art, for example, the method comprising the following steps:

[0037] 1) rolling the steel strip with X1 composition into U shape, then adding the powder with X2 composition in the U-shaped groove, the total composition X of X1 and X2 is within the composition scope of the present invention;

[0038] 2) Close the U-shaped groove, wrap the powder core in it, form, draw and reduce the diameter, and finally obtain the required wire.

[0039] The iron-based thermal spraying powder can be obtained, for example, in the following ways: directly prepare the metal powder with pure metal powder or alloy powder; prepare the required components in powder or block form with pure metal or alloy, and atomize it into powder. The atomization method can be adopted but not limited to water atomization or gas atomization; the pure metal or alloy is formulated into the required compos...

Embodiment

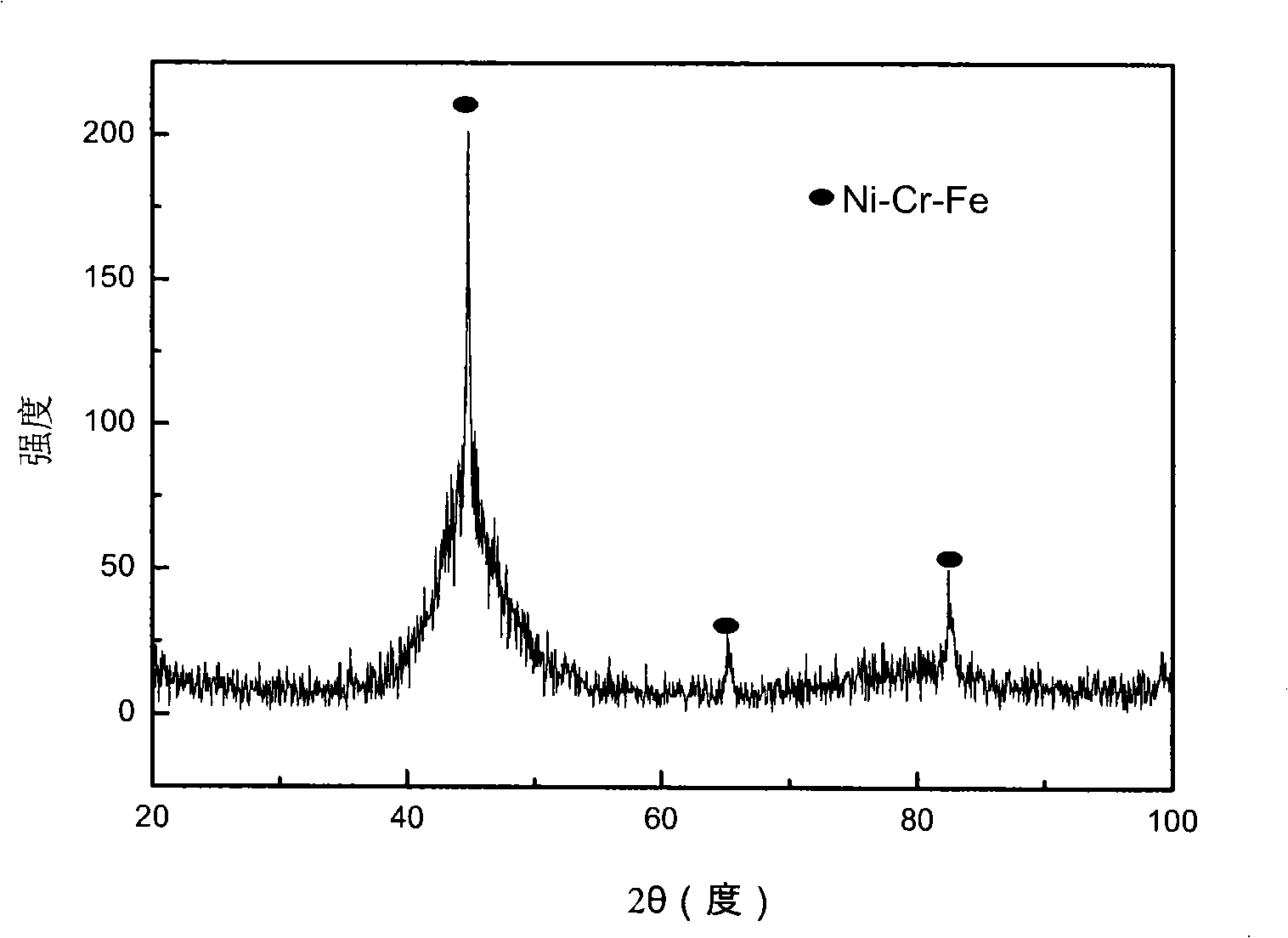

[0048] In this example, the amorphous and nanocrystalline coating of the present invention was prepared by twin-wire arc spraying method and plasma spraying method, and the composition of the coating is shown in Table 1.

[0049] Specifically, when the coating is prepared by twin-wire arc spraying, the above-mentioned components are prepared into a drug core wire. Among them, the coating is FeCr16 steel strip. According to the composition shown in Table 1, the drug core is selected from Fe powder, Cr powder, Ni powder, Si powder, Cu powder, Mo powder, V powder, Zr powder, Y powder, Ga powder, Al powder, Sn powder, WC powder , Fe-B powder, Fe-Mn powder, Fe-P powder and Fe-Nb powder. The particle size of the powder is 60-200 mesh. The overall composition of the obtained powder core wire satisfies the above table 1 composition shown. The coating was prepared on the Q235 steel plate by arc spraying. The spraying process parameters were: arc voltage 34V, working current about 200...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com