Method for processing waste gas generated in isophthalonitrile production process

A technology for isophthalonitrile and waste gas, which is applied in the direction of separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of difficult preparation of thiamine, high processing costs, and complicated processes, so as to prevent secondary pollution, The effect of thorough treatment and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] like figure 1 Shown, a kind of method for processing isophthalonitrile production waste gas, the waste gas flow rate that comes from the isophthalonitrile production line is 1.5m 3 / h, firstly enter the preprocessor to remove impurities, and then enter the heat exchanger. In the heat exchanger, the exhaust gas and the exhaust gas after combustion conduct heat exchange without contact, so as to make full use of thermal energy and reduce energy consumption. Then enter the catalytic combustion furnace for low-temperature catalytic combustion (200 ~ 250 ℃), place 200g catalyst in the catalytic combustion furnace, hydrogen cyanide (HCN) is selectively oxidized by the catalyst into non-toxic nitrogen, carbon dioxide, water, and ammonia gas in At this temperature, it does not substantially participate in the reaction, but is retained. The exhaust gas after decyanation enters the heat exchanger, preheats the exhaust gas to be treated, is cooled, and then enters the water cool...

Embodiment 2

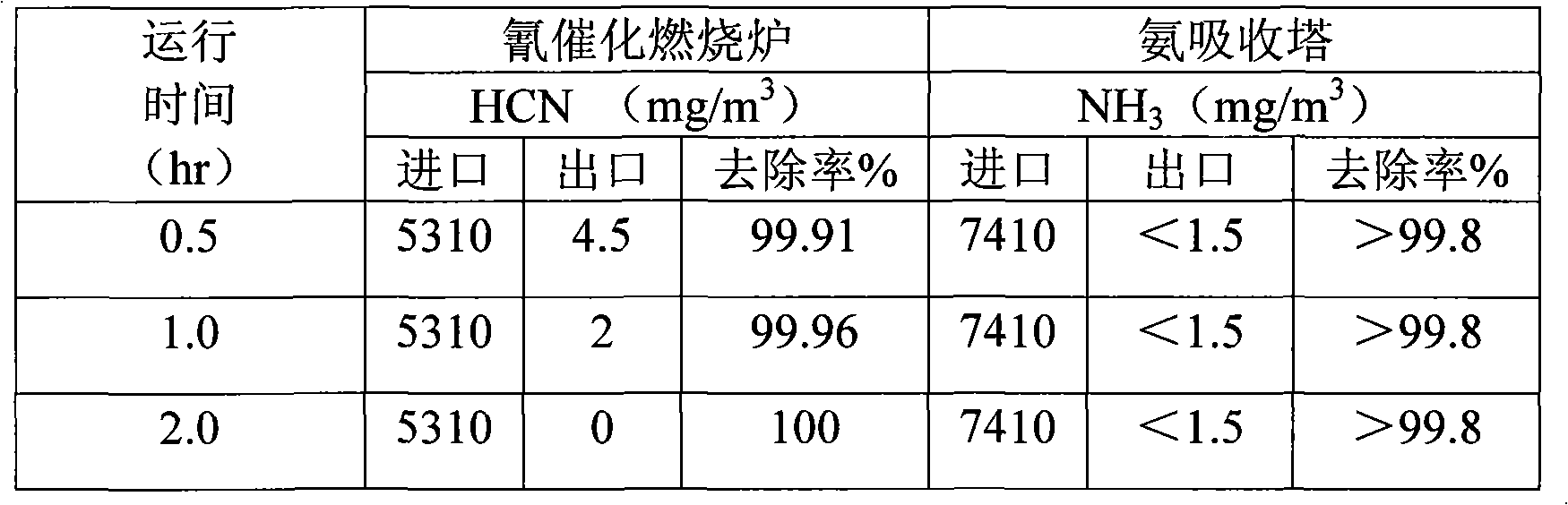

[0024] see figure 1 As shown, the second batch of isophthalonitrile production waste gas is treated, and the specific process is the same as that in Example 1, and the specific data are shown in Table 2 below:

[0025] The data table of table 2 embodiment 2 processing isophthalonitrile production waste gas

[0026]

Embodiment 3

[0028] see figure 1 As shown, the third batch of isophthalonitrile production waste gas is treated, and the specific process is the same as that in Example 1, and the specific data are shown in Table 2 below:

[0029] The data table of table 3 embodiment 3 processing isophthalonitrile production waste gas

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com