Zinc oxide based transparent electric conductor, sputtering target for forming of the conductor and process for producing the target

A transparent conductor, zinc oxide technology, applied in the direction of oxide conductors, sputtering plating, non-metallic conductors, etc., can solve the problems of reducing the resistivity, the effect of reducing the resistivity, insufficient and other problems, and achieve good wettability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

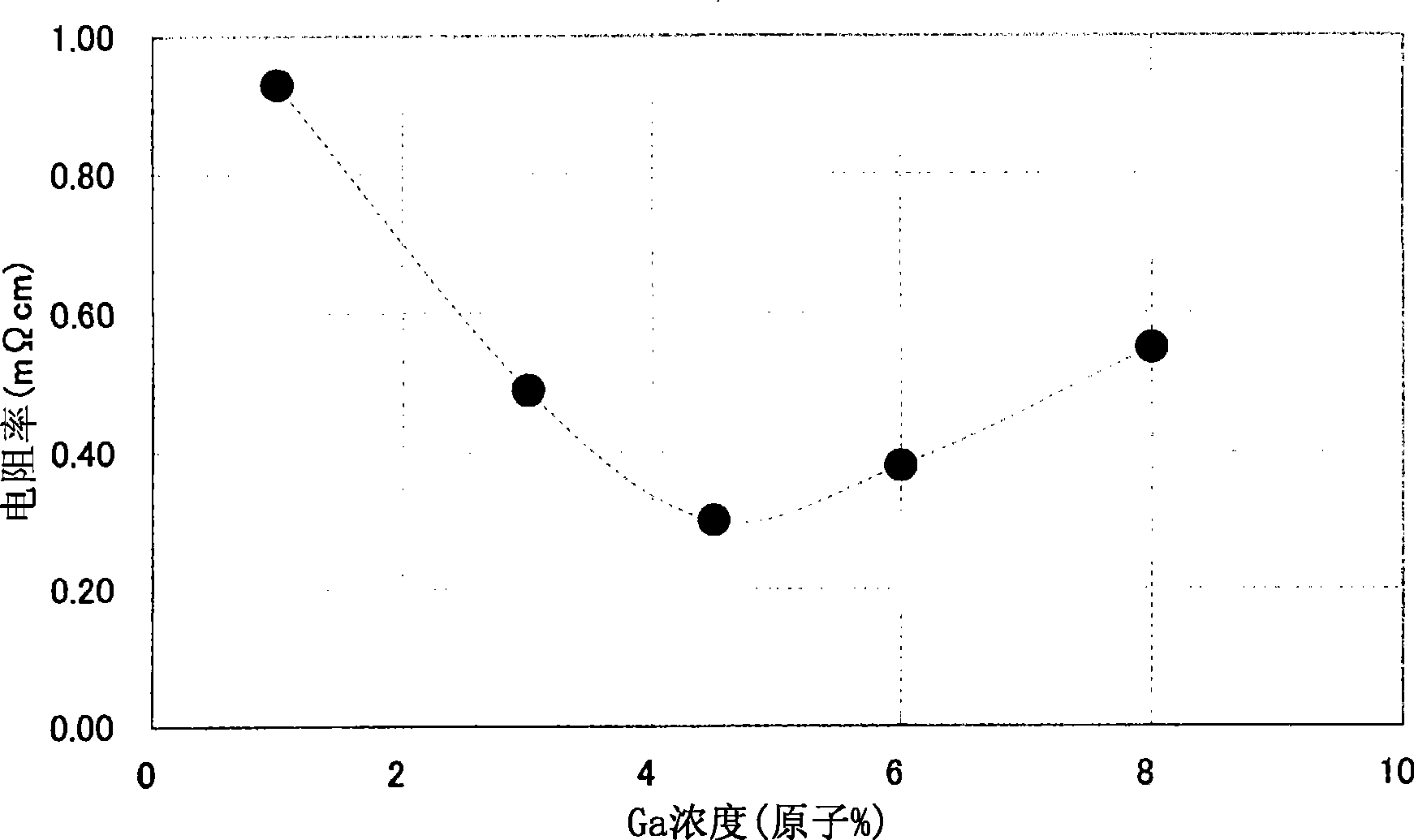

[0058] (Characteristic Confirmation Test 1)

[0059] Weigh zinc oxide and gallium oxide (Ga 2 o 3 ) each raw material powder, as shown in sample numbers 1-5 in Table 1, the atomic ratio of ZnO and Ga as its constituent elements is in the range of ZnO:Ga=99.00-92.00:1.000-8.000. That is, the atomic concentration ratio of Ga to the total amount of Ga and ZnO was varied between 1.000 and 8.000 atomic %. Specifically, the weight of each raw material to be weighed can be easily obtained by calculation from the above-mentioned atomic number ratio and molecular weight of each weighed raw material.

[0060] After mixing the weighed raw materials, use a zirconia ball with a diameter of 3 mm to finely pulverize the raw material powder with a grinder for about 1 hour, sieve it through a 60-mesh sieve, and keep it in a drying oven set at 120°C For 24 hours, the moisture in the raw material was evaporated. The dried raw materials were sieved again with a 60-mesh sieve, and thoroughly m...

Embodiment 2

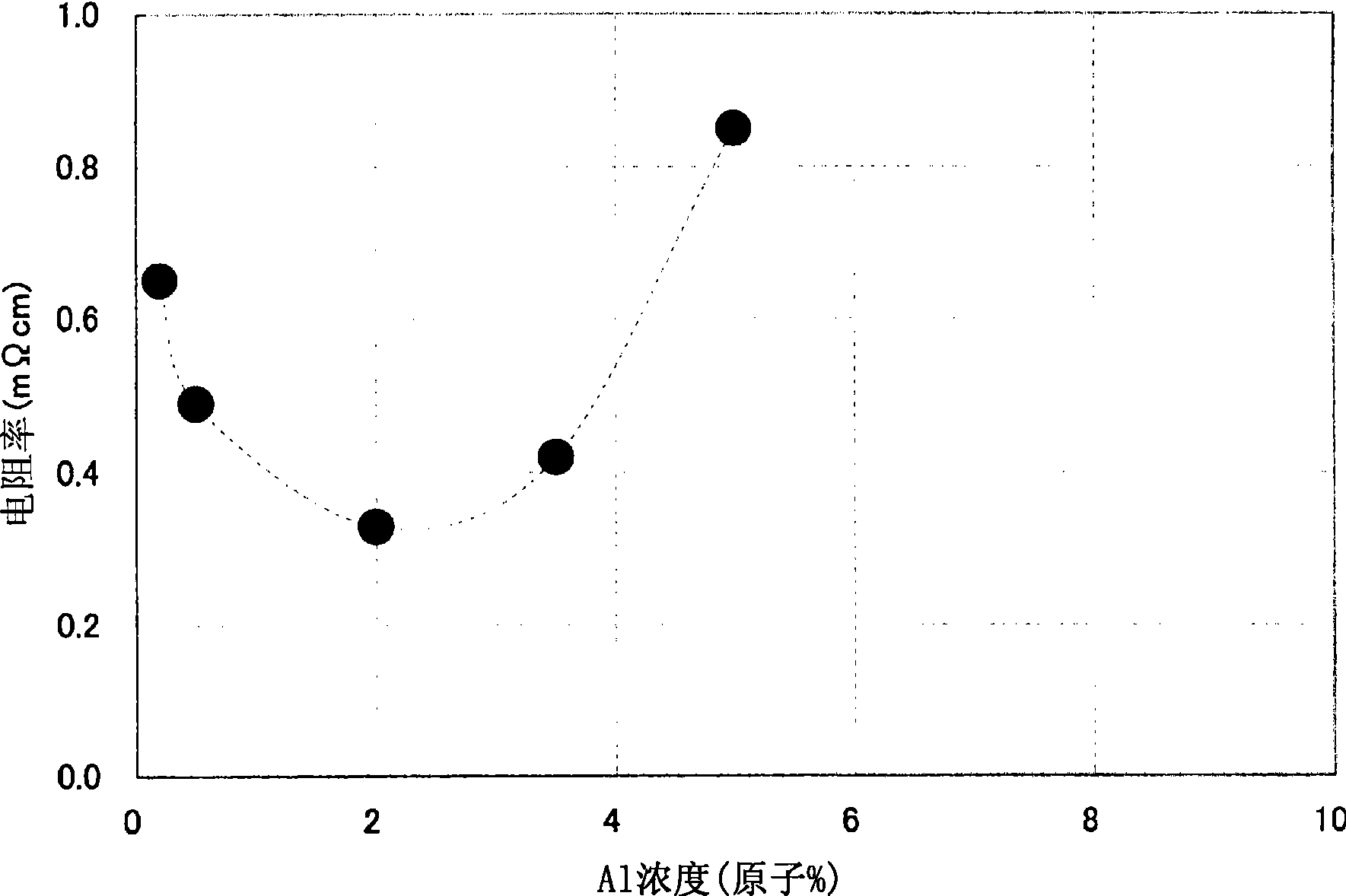

[0112] (Characteristic Confirmation Test 7)

[0113] Weigh zinc oxide and aluminum oxide (Al 2 o 3 ) each raw material powder, as shown in sample numbers 101-105 in Table 2, the atomic ratio of ZnO and Al as its constituent elements is in the range of ZnO:Al=99.80-95.00:0.200-5.000. That is, the atomic concentration ratio of Al with respect to the total amount of Al and ZnO was changed within 0.200 to 5.000 atomic %. Specifically, the weight of each raw material to be weighed can be easily obtained by calculation from the above-mentioned atomic number ratio and molecular weight of each weighed raw material.

[0114] After mixing the weighed raw materials, use a zirconia ball with a diameter of 3 mm to finely pulverize the raw material powder with a grinder for about 1 hour, pass through a 60-mesh sieve, and keep in a drying oven set at 120°C For 24 hours, the moisture in the raw material was evaporated. The dried raw materials were sieved again with a 60-mesh sieve, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com