Resin composition for retardation thin film, color filter substrate for liquid crystal display device, liquid crystal display device, and method for production of color filter substrate for liquid cry

A technology of liquid crystal display devices and retardation films, which can be applied to instruments, optical filters, polarizing elements, etc., and can solve problems such as sufficient transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

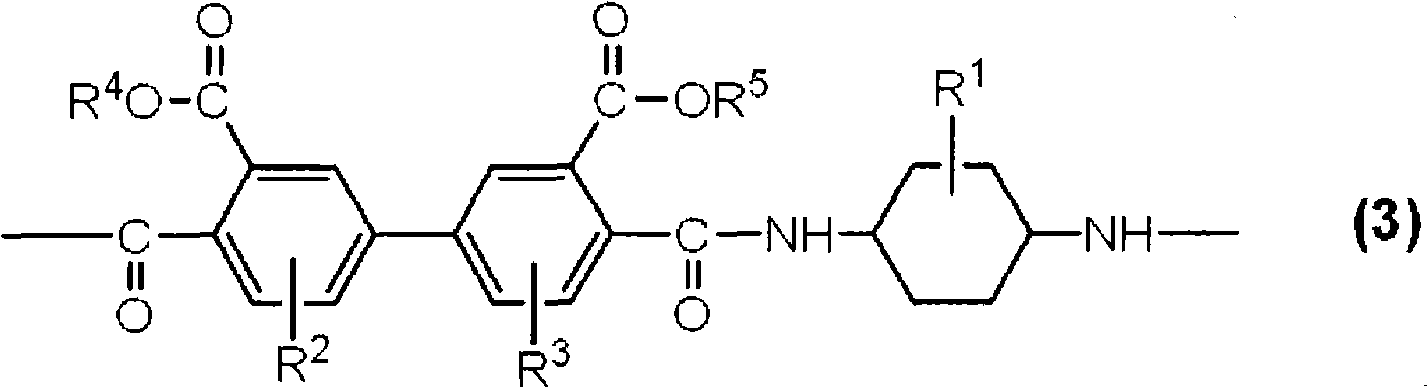

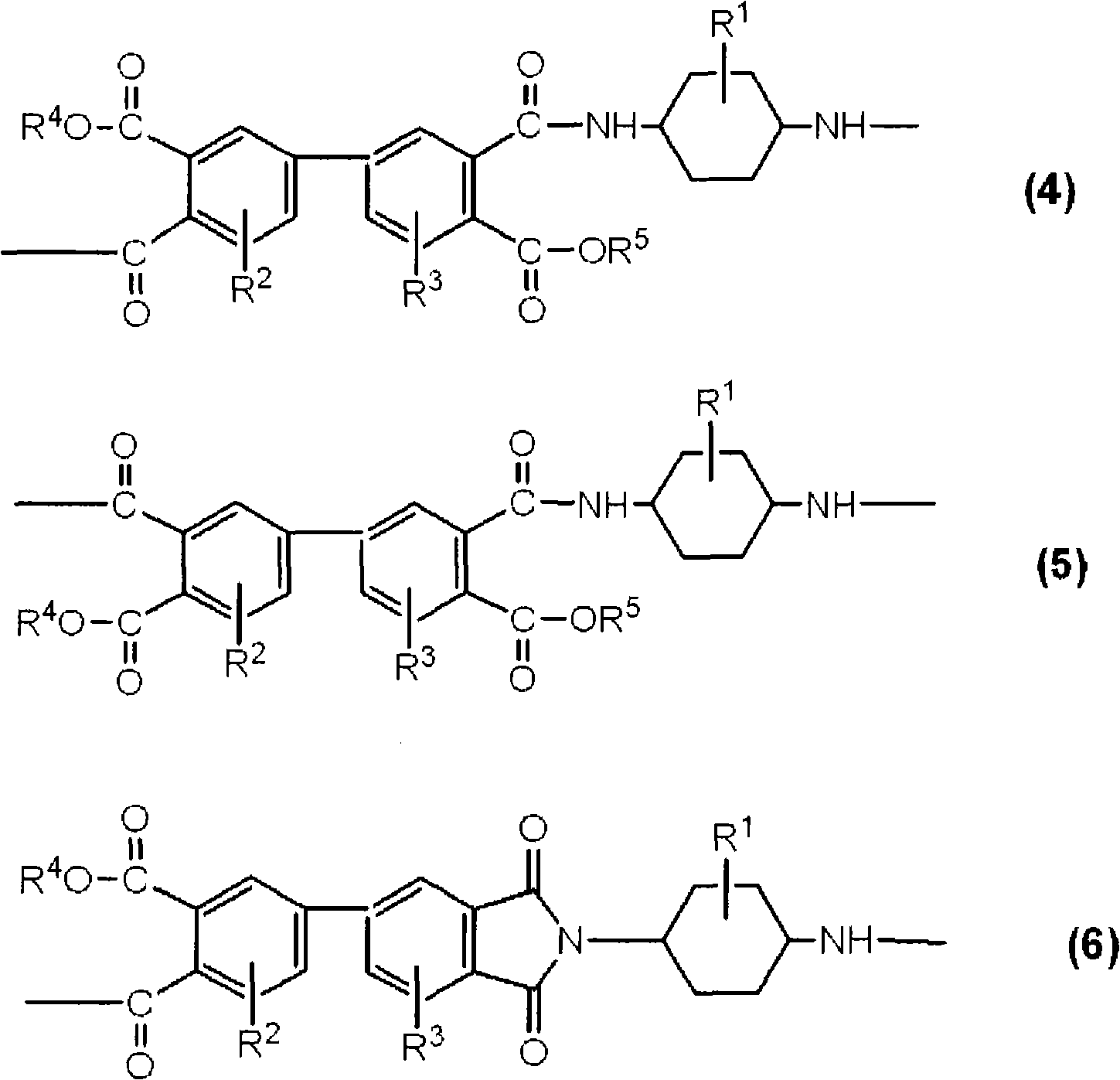

Method used

Image

Examples

Embodiment

[0119]

[0120] The polyimide precursor was dissolved in N-methylpyrrolidone so that the concentration would be 0.5 g / dl, and the diluted solution was measured at 30° C. using an Ubbelohde type viscometer.

[0121]

[0122] Measurement was performed using "OPTIPRO" manufactured by Syntec Corporation.

[0123] Coat the polyimide precursor solution with a spinner on a glass substrate so that the finished thickness is 2.0 μm, then dry at 120°C for 20 minutes, and heat treat at 240°C for 30 minutes or at 270°C for 40 minutes, thereby A polyimide resin film was obtained. The refractive index anisotropy of the polyimide resin film in the direction parallel to the film surface and the refractive index anisotropy in the direction perpendicular to the film surface were measured.

[0124]

[0125] Measurement was performed using "Prizum Capra-2010" manufactured by Metrocon Corporation.

[0126] Coat the polyimide precursor solution with a spinner on a glass substrate so that the...

Synthetic example (1

[0131] Synthesis example (synthesis of 1,2,3,4-cyclobutanetetracarboxylic dianhydride)

[0132] 225 g (2.60 moles) of maleic anhydride and 1445 g of ethyl acetate were added to a reaction flask made of internally illuminated glass with an internal volume of 2 liters and equipped with a water-cooled lampshade made of Pyrex (registered trademark) glass, and the inside of the flask was replaced with nitrogen, and then Stir at room temperature to dissolve. While continuing to stir, the reaction solution was cooled to 5°C, and then began to irradiate with a 400W high-pressure mercury lamp, and continued to irradiate for 96 hours. During the irradiation, the temperature of the reaction solution was kept at 3 to 5°C. After the reaction was complete, the crystals and the filtrate were separated by filtration. The crude crystals were washed with ethyl acetate, and then dried at 40° C. for 10 hours with a vacuum dryer to obtain 194 g of crystals of 1,2,3,4-cyclobutanetetracarboxylic d...

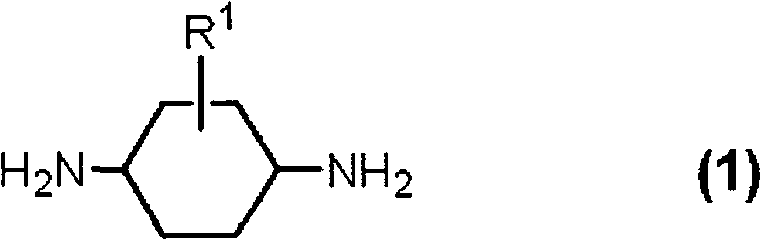

Embodiment 1

[0134] Under a stream of dry nitrogen, 10.96 g (0.096 mol) of trans-1,4-diaminocyclohexane and 0.99 g (0.004 mol) of bis(3-aminopropyl)tetramethyldisiloxane were dissolved to 177.28 g In N-methyl-2-pyrrolidone. Then, 28.25 g (0.096 mol) of 3,3',4,4'-biphenyl tetracarboxylic dianhydride and 40.00 g of N-methyl-2-pyrrolidone were added, and it stirred at 60 degreeC for 3 hours. Further, 1.18 g (0.008 mol) of phthalic anhydride was added, followed by stirring at 60° C. for 3 hours to obtain a transparent and viscous polyamic acid solution A (polymer concentration: 16% by weight). The viscosity of solution A measured at 25° C. was 830 mPa·s. The reduced viscosity is 0.70dl / g.

[0135] Polyamic acid solution A was coated on a glass substrate with a spinner so that the finished thickness was 2.0 μm, dried at 120° C. for 20 minutes, and further heat-treated to obtain a polyimide resin film. When heat-treated at 240° C. for 30 minutes, the polyimide resin film has no refractive ind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com