Preparation of nano hydroxylapatite powder

A nano-hydroxyapatite and powder technology, applied in the chemical field, can solve the problems of unfavorable hydroxyapatite powder, complex production process, easy to leave residues, etc., and achieve convenient and easy purchase of raw materials, high purity, and particle size Narrow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

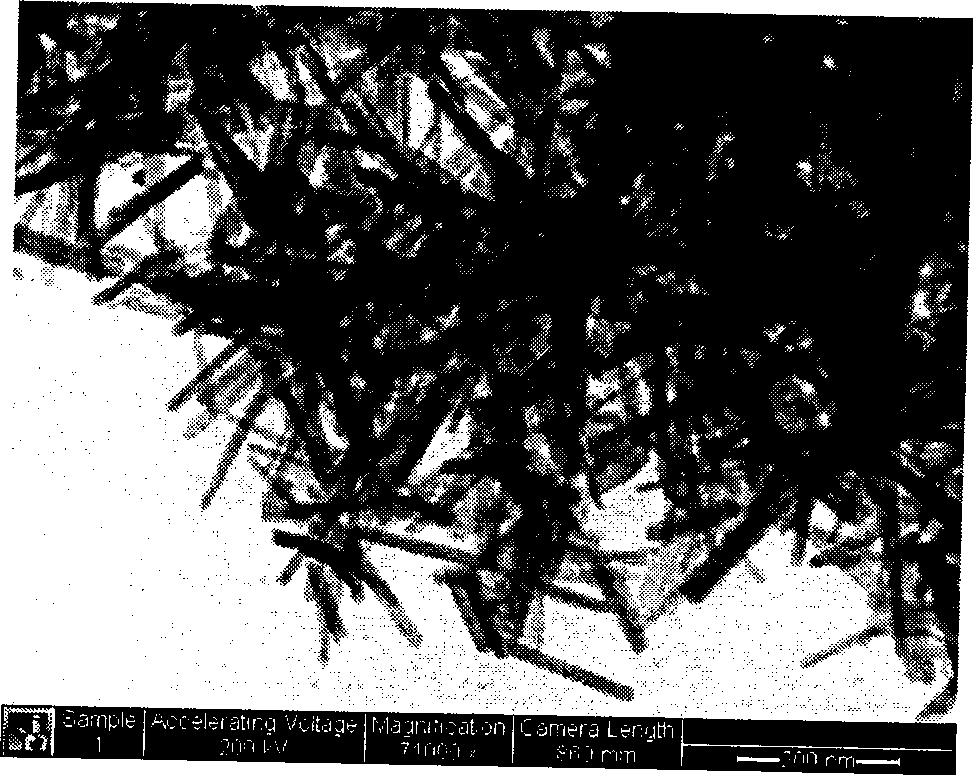

[0032] Weigh 11.8055g of analytically pure calcium nitrate and 11.4146g of analytically pure dipotassium hydrogen phosphate, dissolve them in 50ml of distilled water respectively, and after stirring evenly, dilute the two solutions to 500ml with distilled water respectively. Calcium nitrate solution measures 183.7ml, and dipotassium hydrogen phosphate solution measures 110ml. After the two solutions are directly mixed, the pH value of the mixed solution is measured to be 5.20, and then the mixed solution is put into a reactor and heated at a stirring speed of 300 rpm. The reaction temperature is 200°C, the holding time is 0.5 hours, and it is cooled with the kettle. The reaction product was filtered using a water circulation vacuum pump, washed alternately with distilled water and ethanol six times, and dried in vacuum at a drying temperature of 85° C. for 5 hours. Characterized by XRD and TEM, the obtained hydroxyapatite particles are rod-shaped, about 200nm long, and the asp...

Embodiment 2

[0034] Weigh 4.3352g of analytically pure calcium nitrate and 2.5198g of analytically pure dipotassium hydrogen phosphate, and dissolve them in 183.7ml and 110.0ml of distilled water respectively. The dipotassium hydrogen phosphate solution was dropped into the calcium nitrate solution drop by drop with a dropper, and the glass rod was continuously stirred during the dropping process. Measure the pH value of the mixed solution to be 5.13, then pour it into the reaction kettle, the stirring speed is 180 rpm in the heating and heat preservation phase, and 100 rpm in the cooling phase, the reaction temperature is 200 ° C, the holding time is 3 hours, and it is cooled with the kettle . After the reaction, the precipitate was filtered with a water circulating vacuum pump, washed alternately with distilled water and ethanol for 5 times, and dried under an air atmosphere at a drying temperature of 78° C. and a drying time of 4.5 hours. Characterized by XRD and SEM, the obtained hydr...

Embodiment 3

[0036] Weigh 4.3426g of analytically pure calcium nitrate and 2.5263g of analytically pure dipotassium hydrogen phosphate, and dissolve them in 183.7ml and 110.0ml of distilled water respectively. The dipotassium hydrogen phosphate solution was dropped into the calcium nitrate solution drop by drop with a dropper, and the glass rod was continuously stirred during the dropping process. After measuring the pH value of the mixed solution, pour it into the reaction kettle, the stirring speed is 180 rpm, the reaction temperature is 200°C, the holding time is 9 hours, and it is cooled with the kettle. After the reaction, the precipitate was filtered with a water circulating vacuum pump, washed alternately with distilled water and ethanol three times, and dried under an air atmosphere at a drying temperature of 78° C. and a drying time of 4.5 hours. The obtained hydroxyapatite particles are rod-shaped with an aspect ratio of about 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com