Aqueous solution containing coenzyme Q10 nano granule and preparation method thereof

A nanoparticle and aqueous solution technology, which is applied in the direction of medical preparations containing active ingredients, medical preparations with non-active ingredients, and pharmaceutical formulas, etc. It can solve the problems of unstable preparations, redox duality, and unstable physical and chemical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

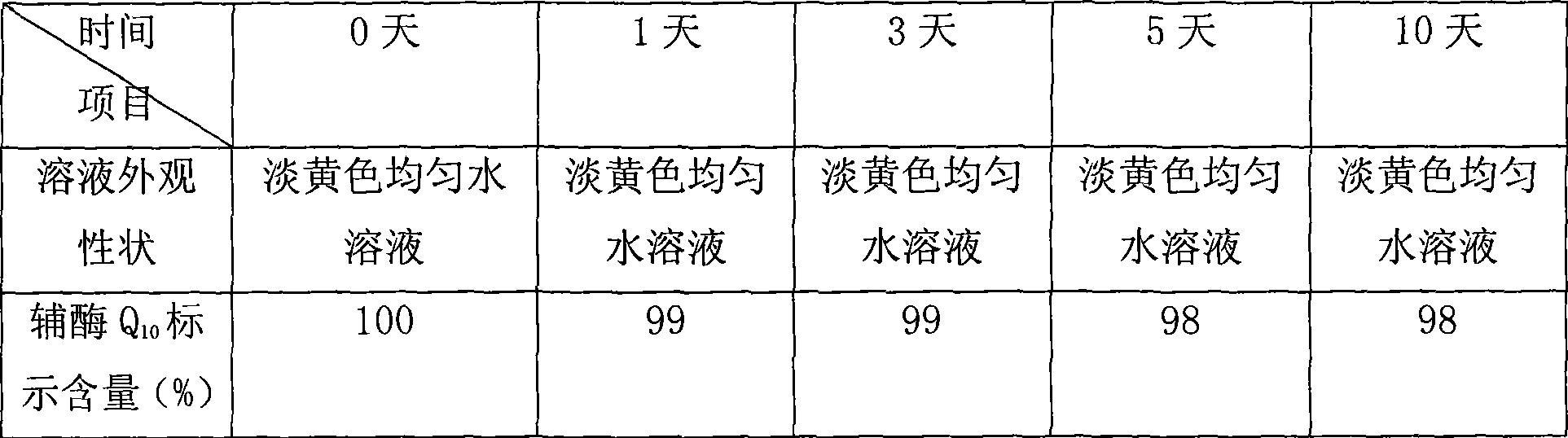

Examples

Embodiment 1

[0039] coenzyme Q 10 4g, HP-β-cyclodextrin 30g, γ-cyclodextrin 6g, hydroxypropyl methylcellulose 3g, purified water 100ml.

[0040] Put cyclodextrin, Tween 80 and hydroxypropyl methylcellulose in 100ml of purified water in the prescription, stir until dissolved, and place in a water bath at 50°C. Prescription Amount Coenzyme Q 10 Heat to dissolve, slowly add to the 60°C water phase solution under high-speed stirring, stir at 5000rpm for 5 minutes, put the material into a high-pressure homogenizer, and homogenize 3 times at 100Mpa. Add 2000ml of purified water, and then discharge the material such as a high-pressure homogenizer 100Mpa to homogenize twice to obtain a light yellow uniform emulsion as the final product.

Embodiment 2

[0042] coenzyme Q 10 3g, HP-β-cyclodextrin 10g, γ-cyclodextrin 20g, Tween 800.5g, sodium carboxymethylcellulose 3g, purified water 100ml.

[0043]Put cyclodextrin, Tween 80 and sodium carboxymethylcellulose in 100ml of purified water in the prescription, stir until dissolved, and place in a 70°C water bath. Prescription Amount Coenzyme Q 10 Heat to dissolve, slowly add to the 70°C water phase solution under high-speed stirring, stir at 9000rpm for 10 minutes, put the material into a high-pressure homogenizer, and homogenize 3 times at 100Mpa. Put the material into the spray dryer, the air inlet temperature is 1220°C, the outlet air temperature is controlled at 115°C, and the light yellow powder is obtained as the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com