Method and apparatus for adding tobacco material

A technology of tobacco materials and feeding equipment, which is applied in the fields of tobacco, tobacco preparation, food science, etc., can solve the problems of low feeding temperature, blockage of ventilation holes, loss of material liquid, etc., to improve the uniformity and accuracy of feeding, and slow down the whereabouts of materials Speed, increase the effect of material-liquid contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

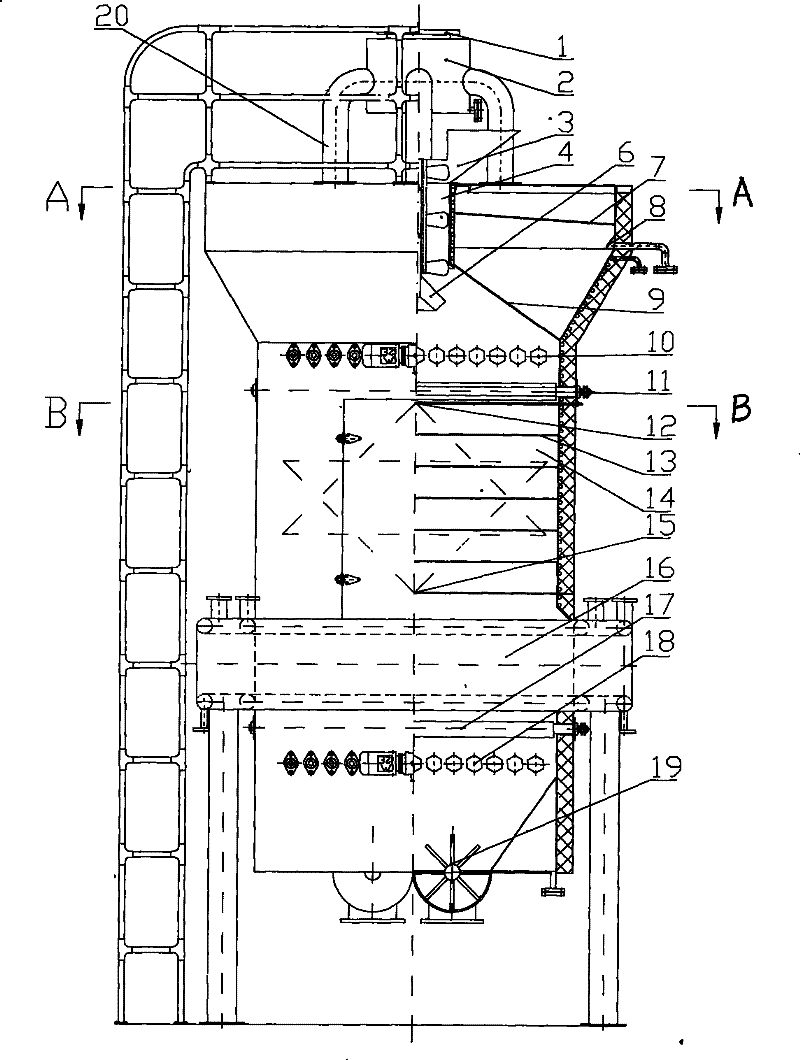

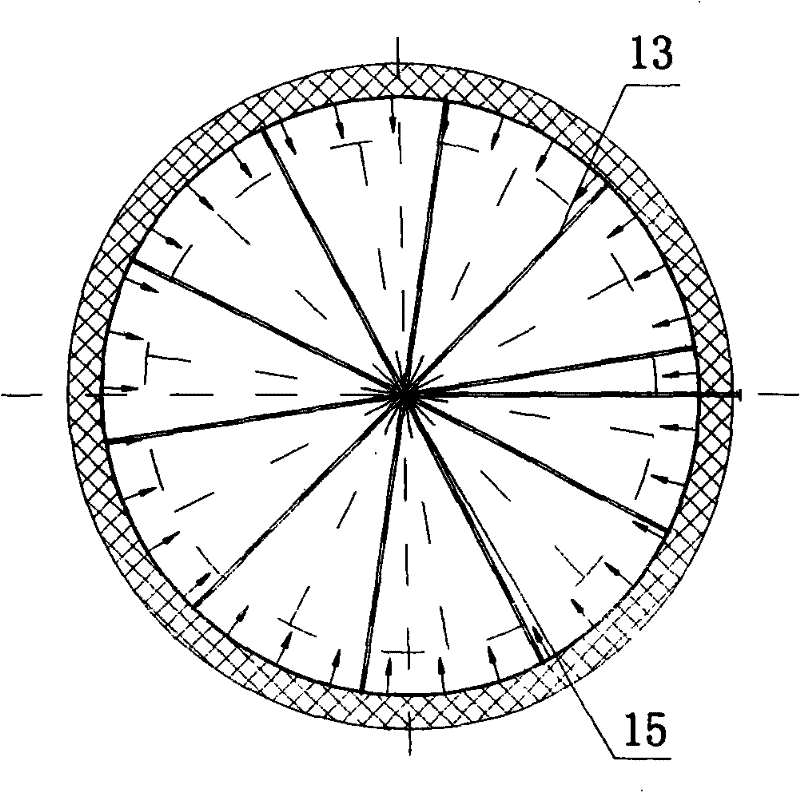

[0032] Such as figure 1 As shown, the tobacco material feeding equipment of the present invention includes a vertical barrel-shaped cavity, and a fan suction port 1, a settling dust removal box 2, and a hot air collection pipe 20 are arranged on the top of the barrel-shaped cavity; In the vertical direction from top to bottom, the feed inlet 3, the feeding screw cylinder, the first group of thinners 10, the second group of thinners 11, the feeding area 14, the third group of thinners 17, and the fourth group of thinners 18 are set in sequence. And discharge air lock 19; an annular heat exchanger 16 is arranged near the lower end of the barrel-shaped cavity.

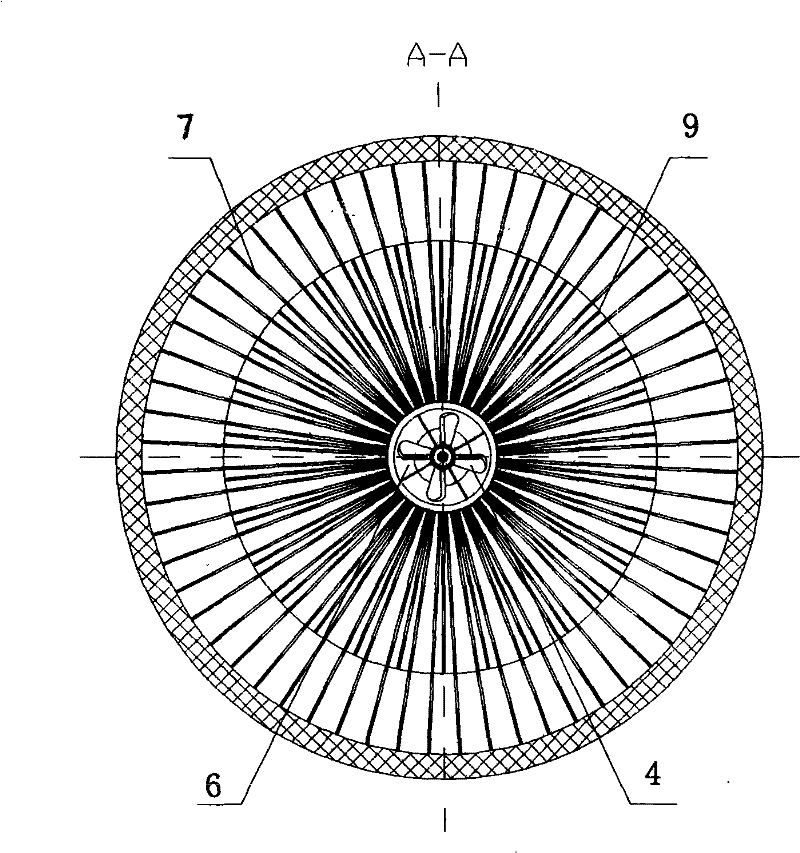

[0033] Such as figure 1 , figure 2 and Figure 4 As shown, the feed screw cylinder 4 vertically arranged at the upper end of the barrel-shaped cavity has its inlet connected to the feed port 3, and its outlet is provided with a material retaining cone plate 6 and a material retaining net 9. The material screen 9 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com