Materiel tracking system of ERW welded pipe product line

A technology of tracking system and production line, applied in the field of material tracking system, to achieve the effect of eliminating the mixing of steel pipes and facilitating production management and assessment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be further described below in conjunction with the accompanying drawings and specific implementation.

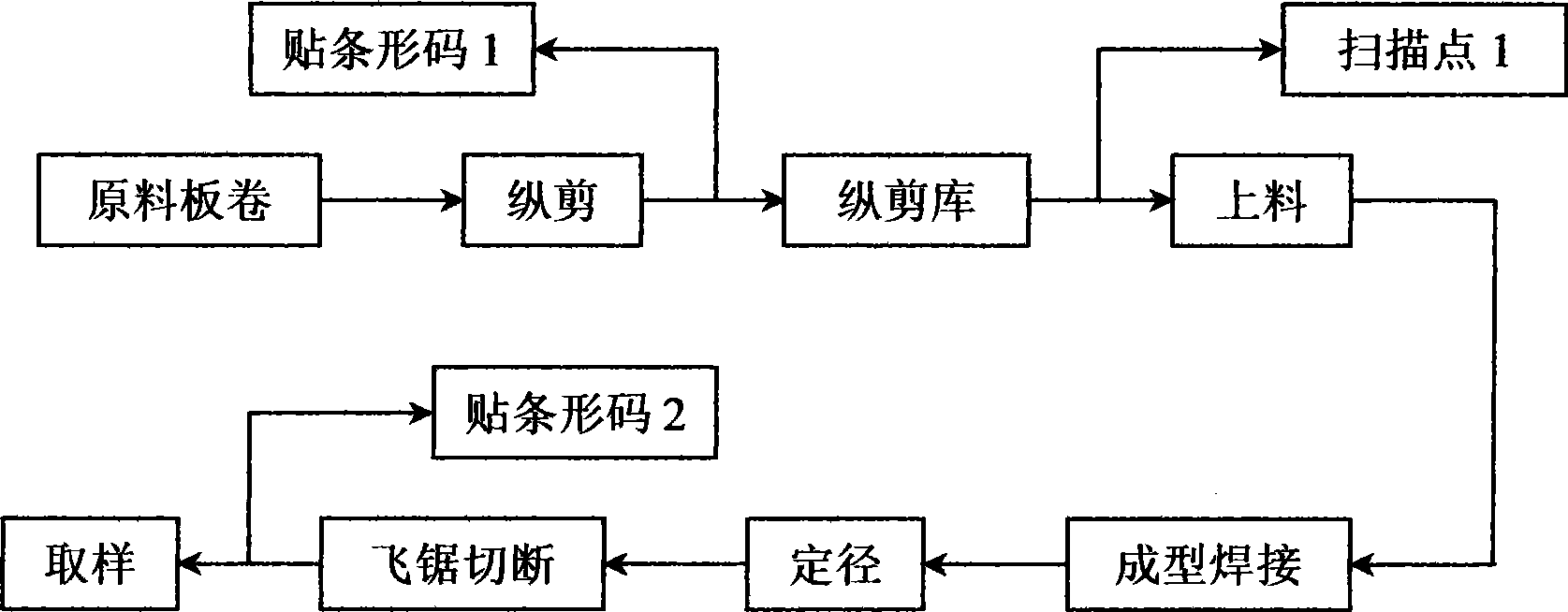

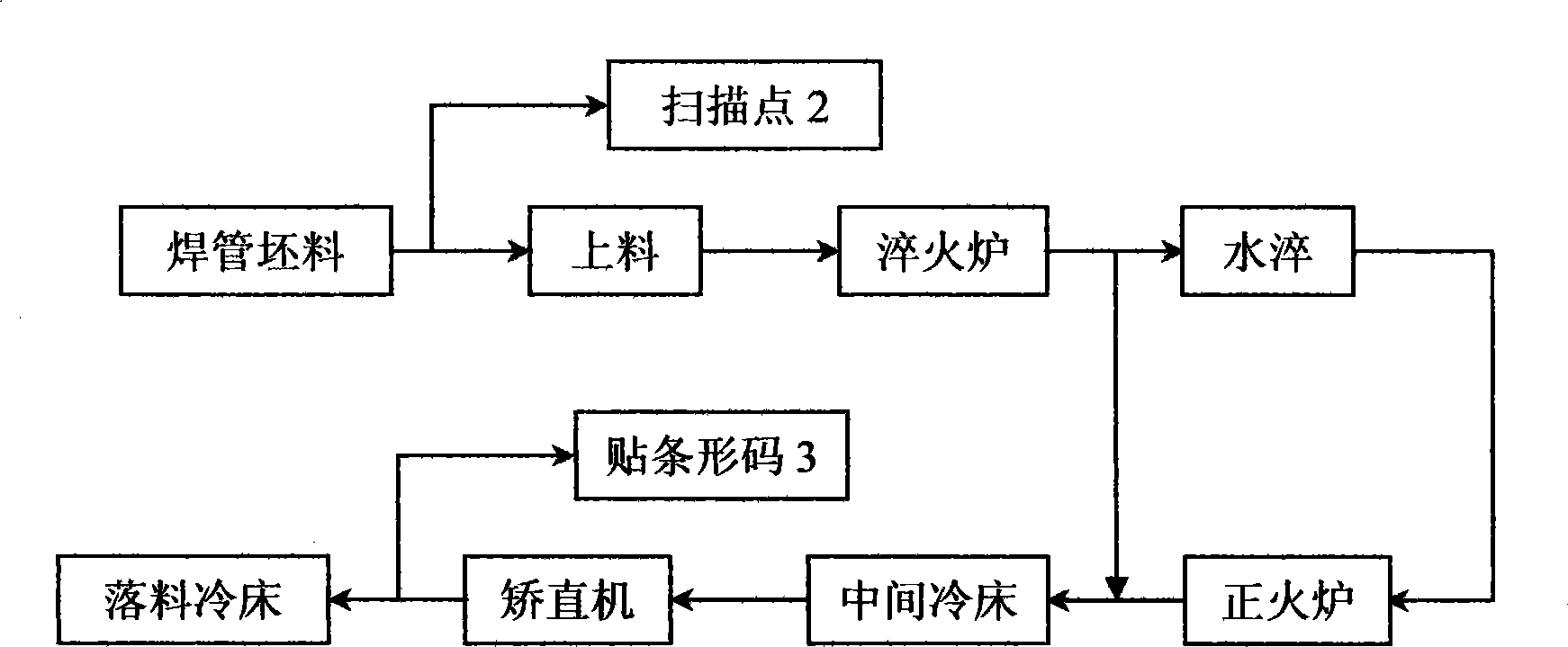

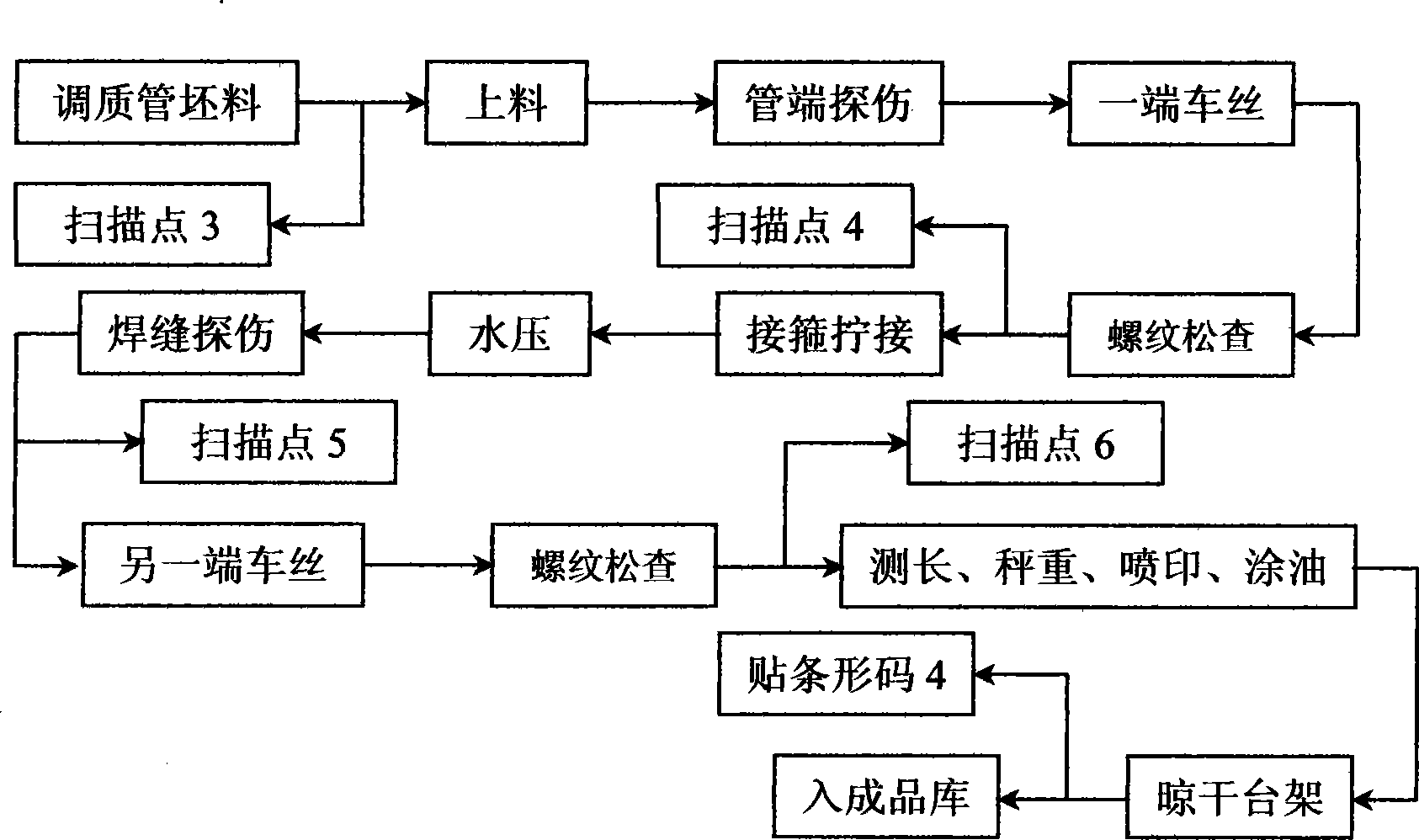

[0018] like figure 1 As shown, the material tracking system method of the ERW welded pipe production line configures a server on the production line dedicated to the material tracking of the steel pipe factory, remotely manages and monitors the production process of each production line in the entire production process of the ERW welded pipe, generates, collects, and maintains Database and output reports. When the hot-rolled steel coil enters the factory, a unique steel coil number is assigned to each steel coil, and the information of the steel coil: manufacturer, production date, furnace number, batch number, steel type, steel grade, chemical composition, specification, The weight, arrival date, storage location, etc. are entered into the database and correspond to the steel coil number, and a barcode is pasted on the inner and outer surfaces of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com