Simulated acceleration test method for coating

An accelerated test and coating technology, which is applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of incomplete simulation accelerated test results and long test period, and achieve the effect of being conducive to application and popularization and reasonable test methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: a kind of simulated accelerated test method of coating, comprising damp heat test, solar radiation test, salt spray test, it is characterized in that: described damp heat test, described solar radiation test, described salt spray test are combined sequentially , and loop.

[0028] The number of cycles of the damp heat test, the solar radiation test and the salt spray test is 12.

[0029] The test time of one cycle of the damp heat test, the solar radiation test and the salt spray test is 72 hours, wherein:

[0030] The damp heat test time is 24 hours, and the test conditions are: 2 hours heating: 30°C to 60°C, 16 hours high temperature and high humidity: 60°C, relative humidity 95%, 2 hours cooling: 60°C to 30°C, 4 hours Hourly low temperature and high humidity: 30°C, relative humidity 85%;

[0031] The solar radiation test time is 24 hours, the test conditions are: 20 hours of solar radiation, light source: 1120±47W / m 2 Water-cooled tubular xenon lamp,...

Embodiment 2

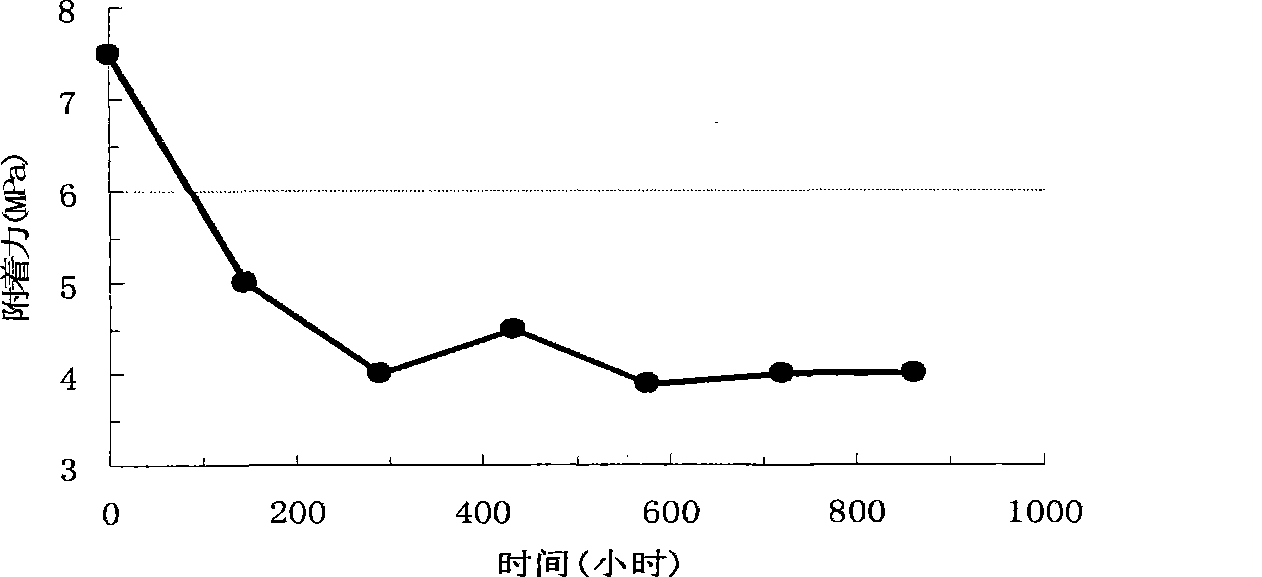

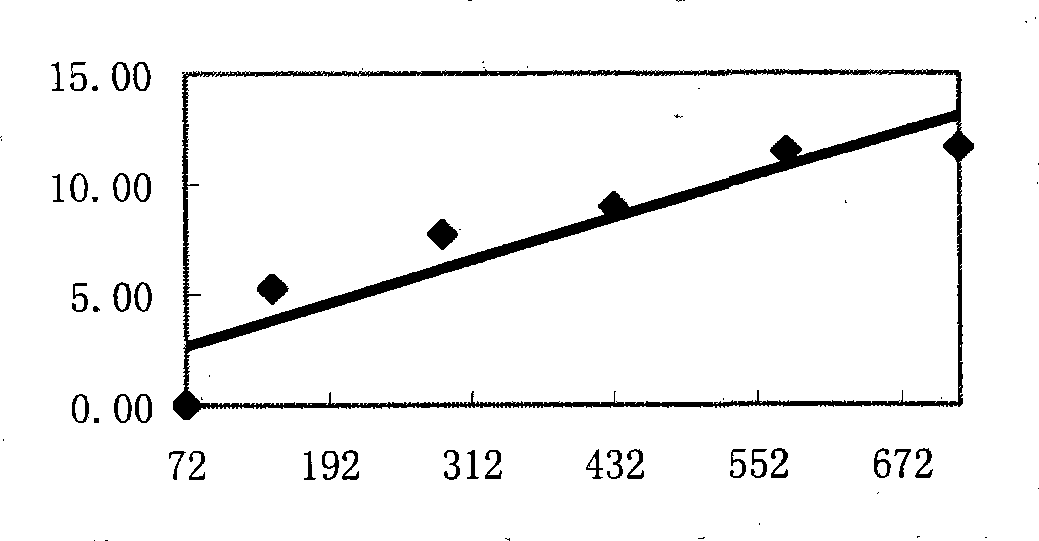

[0057] Embodiment 2: a kind of simulated accelerated test method of coating, present embodiment is except that the sample coating that adopts is the same kind of coating with the sample different batches of embodiment 1, implemented simulated accelerated test method, Test equipment, sample detection etc. are all the same as in Example 1. The appearance evaluation results of the samples in the test are shown in Table 3; Figure 5 .

[0058] Table 3 Appearance evaluation results of samples in damp heat-solar radiation-salt spray cycle test

[0059] Test time (h) discoloration chalking bubbling rust Comprehensive grade 0 0 0 0 0 0 72 0 0 0 0 0 144 1 1 0 0 1 288 1 1 0 0 1 432 2 1 0 0 1 576 3 2 0 0 2 720 3 3 0 1(S3) 3 864 4 3 1 2(S3) 4

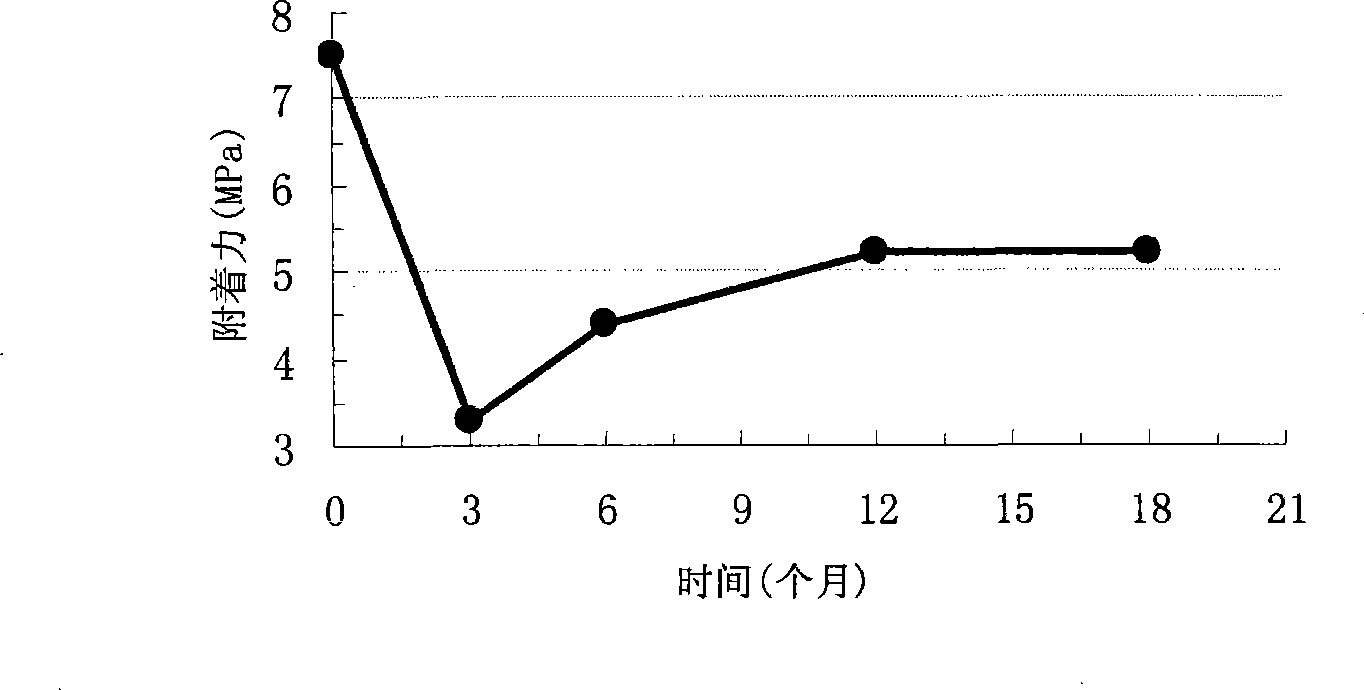

[0060] Same as embodiment 1, also adopted the same batch of coating samples identical with the present embodiment to carry out the natural environment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com