UV curing photosensitive resin for rapid moulding injection mold

A photosensitive resin and injection mold technology, which is applied in the field of UV-cured photosensitive resin for rapid prototyping injection molds, can solve problems such as resin research reports that have not yet been seen, and achieve the effects of reducing material costs, wide range of material selection, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation method of E-44 epoxy acrylate monoester is as follows: the tetrabutyl ammonium bromide of the E-44 epoxy resin (Shanghai Tianyuan Resin Factory), 0.5g of 114g, 0.5g is put into In the four-necked flask with a thermometer, after heating to 90°C, 11.1 g of acrylic acid was added dropwise, then the temperature was raised to 110°C, and the reaction ended when the acid value was <3.

[0047] Photosensitive resin raw material quality composition: self-made synthetic E-44 epoxy acrylate monoester: E-44 epoxy resin (Shanghai Tianyuan Resin Factory): epoxy acrylate diester (Changxing Chemical Industry Co., Ltd.) = 1:1:1 (Total 7kg); Reactive diluent SR-379 (ie glycidyl methacrylate) (Sartomer, USA): 3kg; Adhesion promoter HMX-23 (Zhejiang Huangma Chemical Group): 0.2kg; Photoinitiator Irgacure184 (Vaporization): 0.25kg; Photoinitiator 250 (Jiangsu Huati): 0.25kg; Leveling agent BYK361 (Germany BYK): 0.01kg; Defoamer BYK066N (Germany BYK): 0.01kg .

[0048] Mix ...

Embodiment 2

[0052] Quality composition of photosensitive resin raw materials: self-made synthetic E-44 epoxy acrylate monoester: E-44 epoxy resin: epoxy acrylate diester = 1:1:1 (total 7kg); reactive diluent SR-379: 3kg; attached Focus accelerator HMX-23: 0.2kg; photoinitiator Irgacure 184: 0.25kg; photoinitiator 201 (Jiangsu Huati): 0.25kg; leveling agent BYK361: 0.01kg; defoamer BYK066N: 0.01kg;

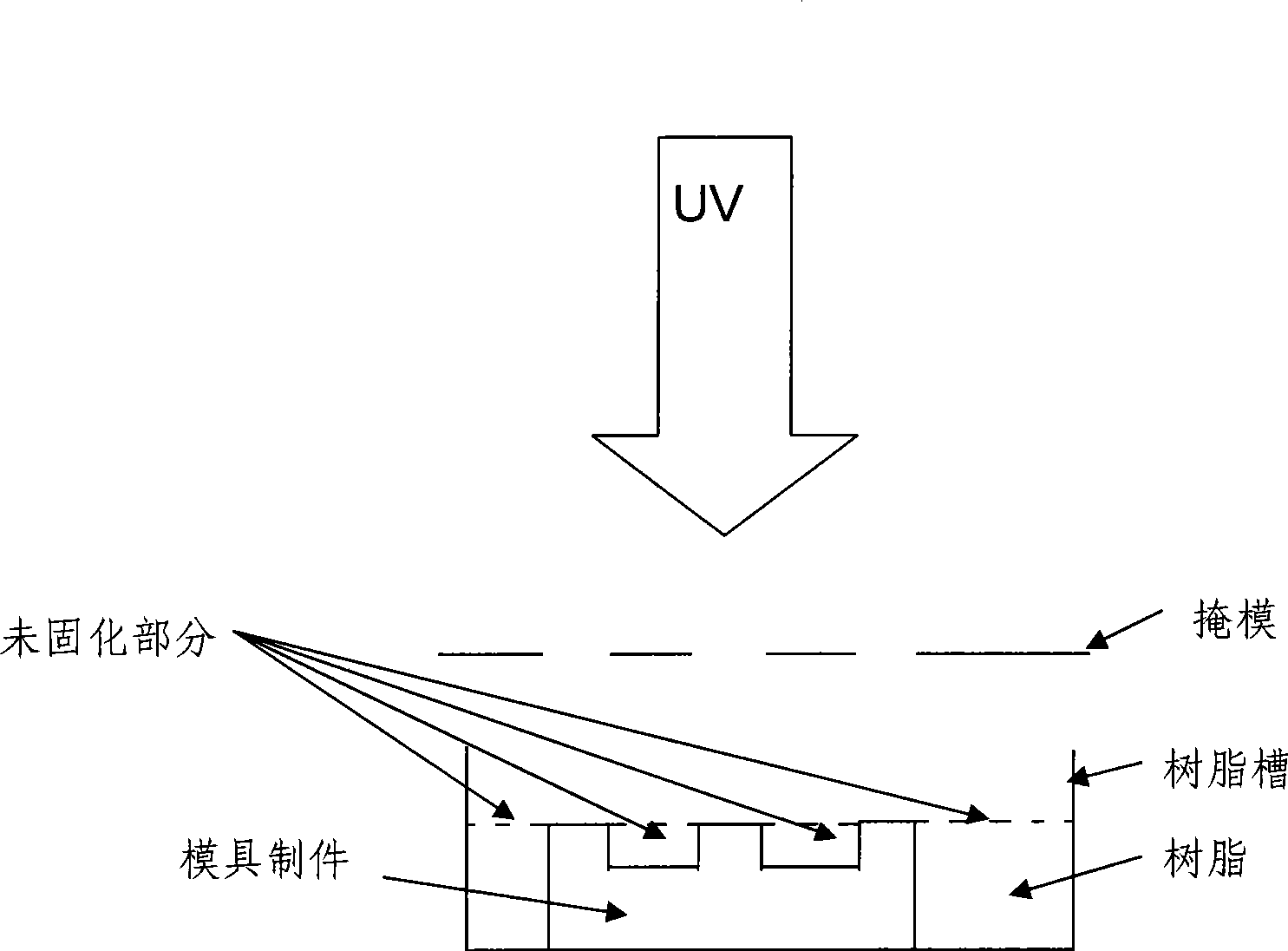

[0053] Mix the resin raw materials, then put the resin into the liquid storage tank under the high-pressure mercury lamp of 1000W, and solidify layer by layer under the action of the mask until it is formed. 2.4KW) post-curing for 2 hours is the required mold.

[0054] ABS (HI-121H Ningbo Lejin Yongxing Chemical Co., Ltd.) was injected using the obtained mold. The processing temperatures were as follows: machine head temperature: 135°C, first zone: 190°C; second zone: 190°C; third zone: 180°C. Holding time: 10s, injection pressure 15Mpa. The mold can be re-injected more than 200 times withou...

Embodiment 3

[0056] Quality composition of photosensitive resin raw materials: self-made synthetic E-44 epoxy acrylate monoester: E-44 epoxy resin: epoxy acrylate diester = 1:1:1 (total 8kg); reactive diluent SR-379: 2kg; attached Focus accelerator HMX-23: 0.2kg; photoinitiator Irgacure 184: 0.25kg; photoinitiator 202 (Jiangsu Huati): 0.5kg; leveling agent BYK361: 0.01kg; defoamer BYK066N: 0.01kg;

[0057] Mix the resin raw materials, then put the resin into the liquid storage tank under the high-pressure mercury lamp of 1000W, and solidify layer by layer under the action of the mask until it is formed. 2.4KW) post-curing for 2 hours is the required mold.

[0058] Nylon-6 (101-3B) was injection-molded using the obtained mold, and the processing temperatures were as follows: machine head temperature: 135°C, first zone: 220°C; second zone: 200°C; third zone: 190°C. The holding time is 50s, and the injection pressure is 45Mpa. The mold can be re-injected more than 200 times without breaking...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com