Full-optical-fiber laser resonance cavity and production process thereof

A technology of lasers and resonators, applied in the structure/shape of optical resonators, the structure/shape of active media, etc., can solve the problems of difficult packaging of pump light-coupled fiber lasers, unfavorable practicality and commercialization of fiber lasers, etc. The preparation method is simple and easy, and the transmission loss is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

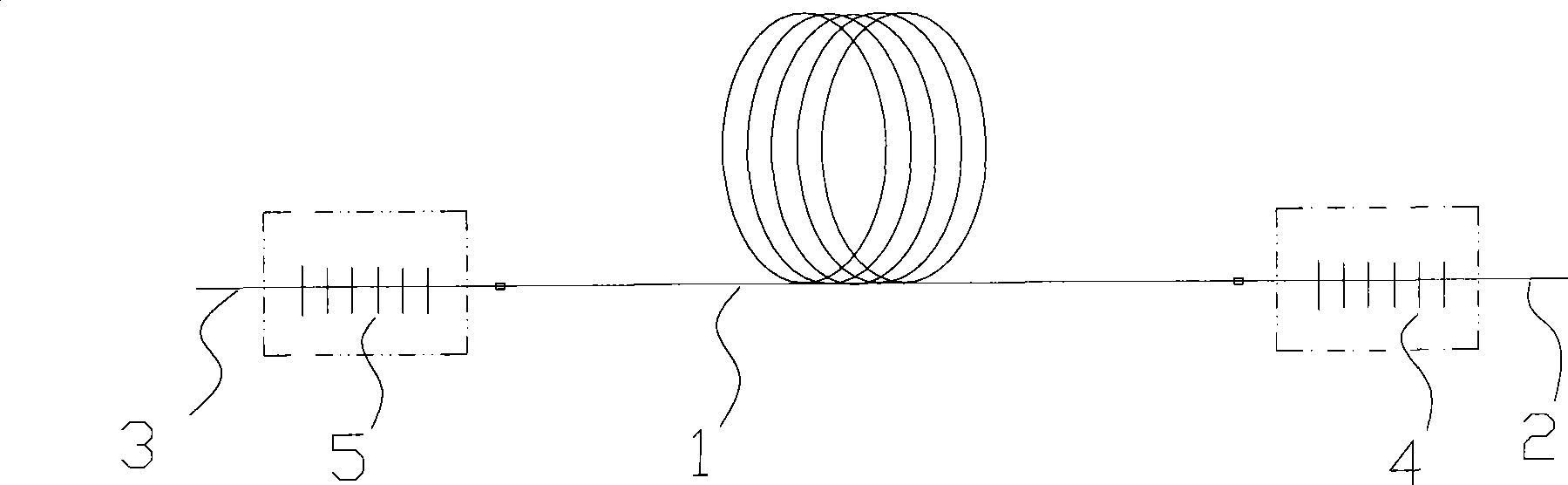

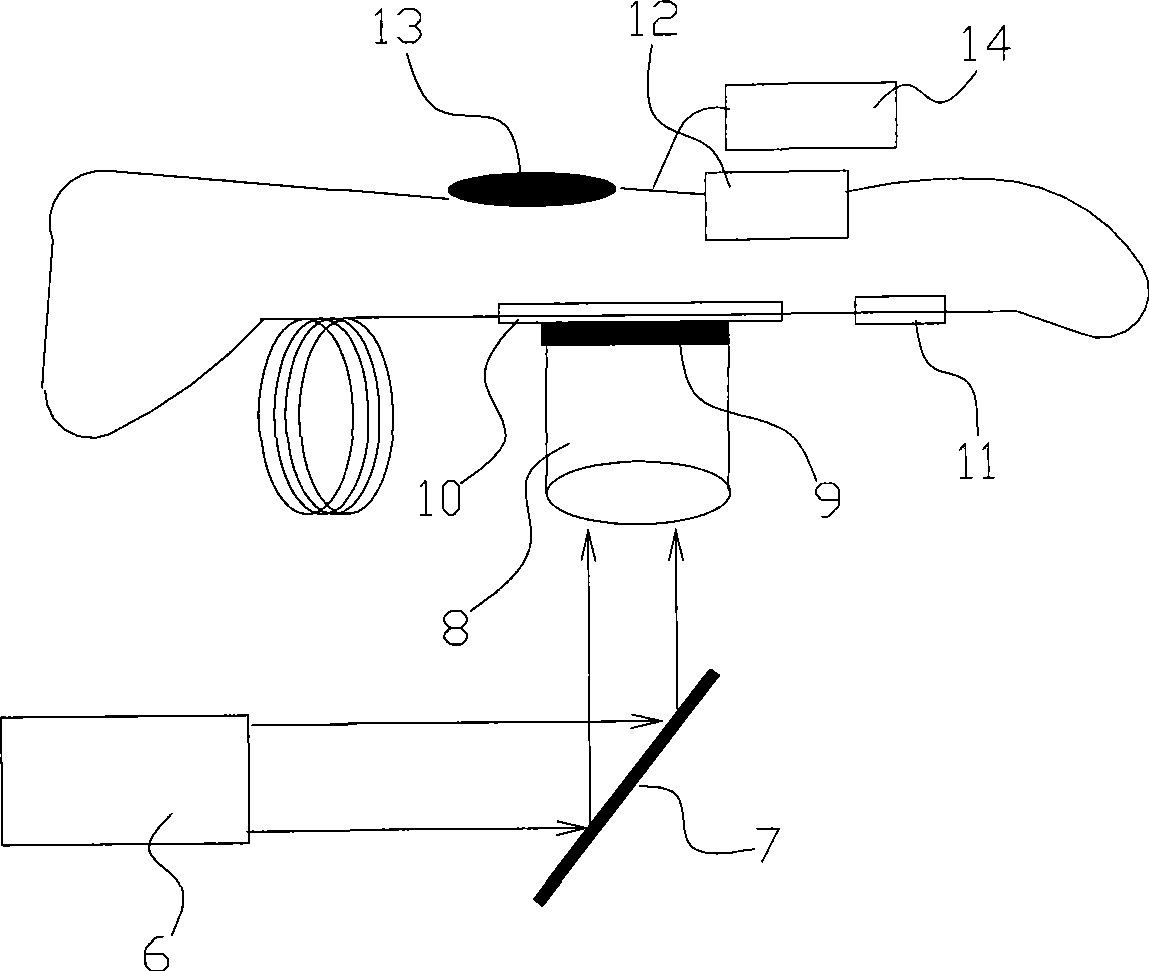

[0021] Such as figure 1 , figure 2 Shown, a kind of all-fiber laser resonator, it comprises doped double-clad fiber 1, the end of this doped double-clad fiber 1 away from the pump source is the front end, and the end close to the pump source is the back end, The resonant cavity also includes a front-end single-mode double-clad fiber 2, a rear-end single-mode double-clad fiber 3, a front-end single-mode double-clad fiber 2, a rear-end single-mode double-clad fiber 3 and a doped double-clad fiber 1 The mode field of the doped double-clad fiber 1 is matched, the front-end single-mode double-clad fiber 2 and the rear-end single-mode double-clad fiber 3 are respectively fused to the front end and the rear end of the doped double-clad fiber 1, and the front-end single-mode double-clad fiber 2, The rear single-mode double-clad optical fiber 3 is engraved with a front-end fiber Bragg grating 4 and a rear-end fiber Bragg grating 5 respectively. The wavelength bandwidths of the front-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com