Residual powder cleaning equipment

A technology for cleaning equipment and residual powder, which is applied to equipment, electrical recording technology, optics, etc. of the electrical recording process using charge graphics, and can solve the problems of low efficiency and high cost of residual powder cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

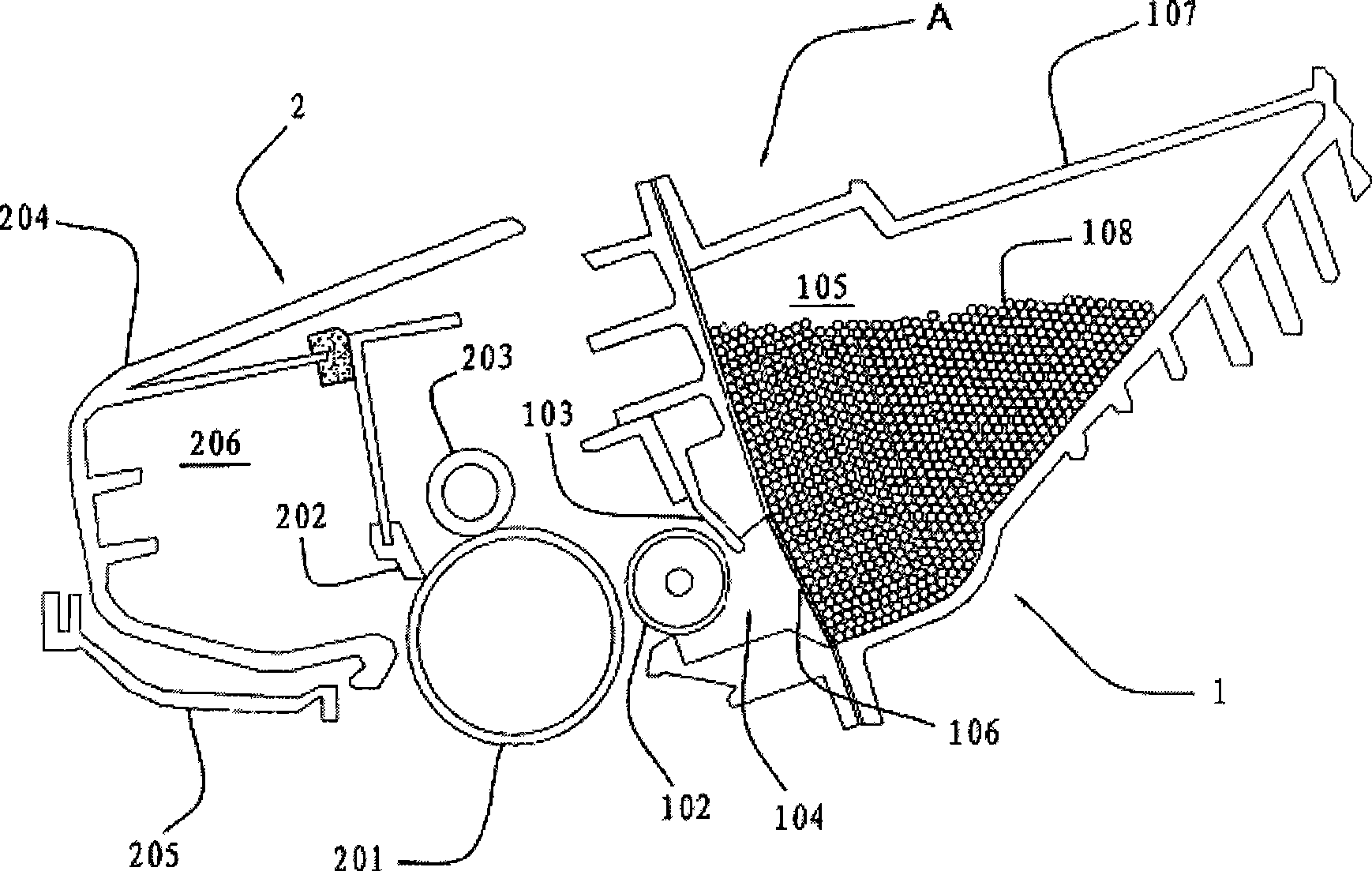

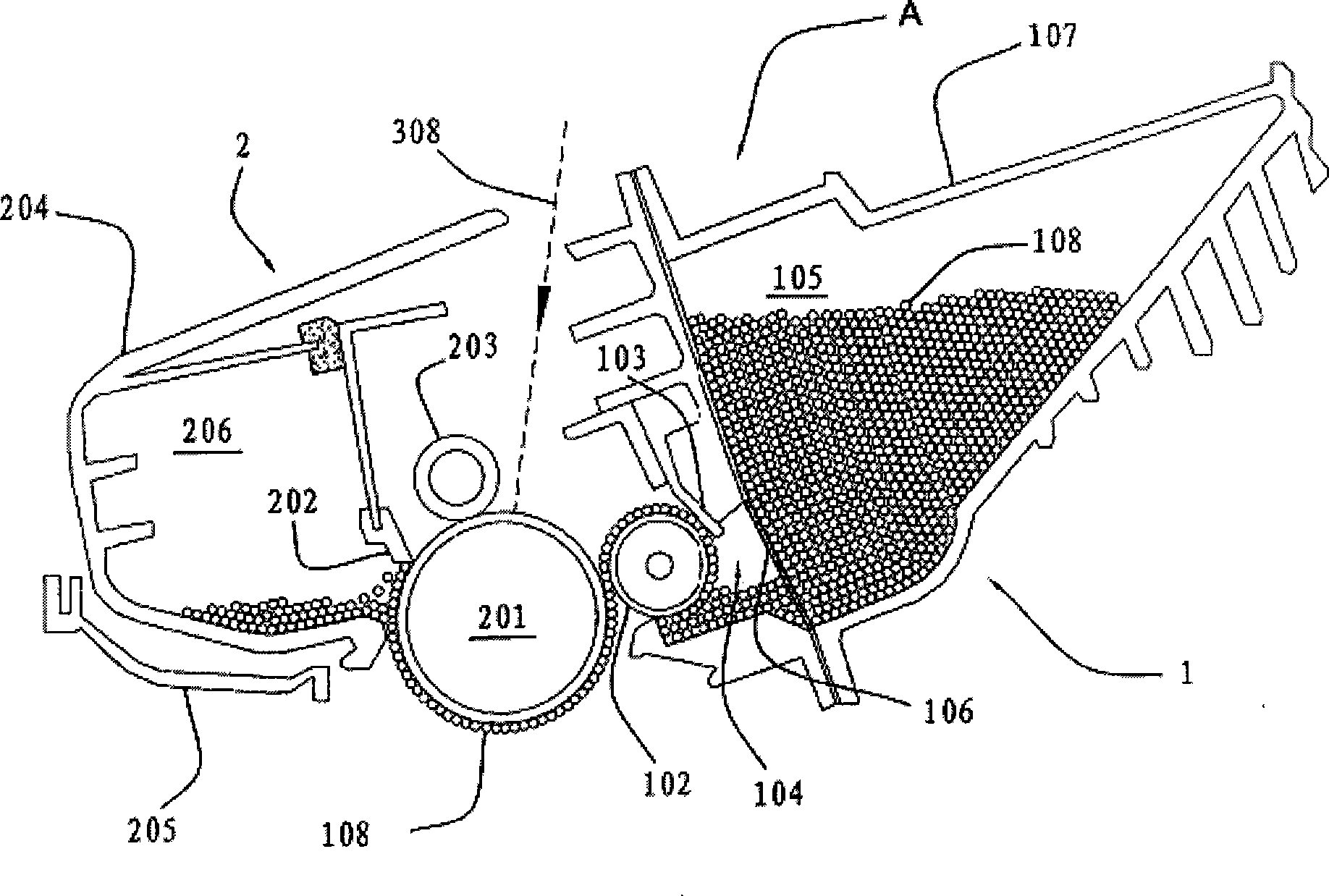

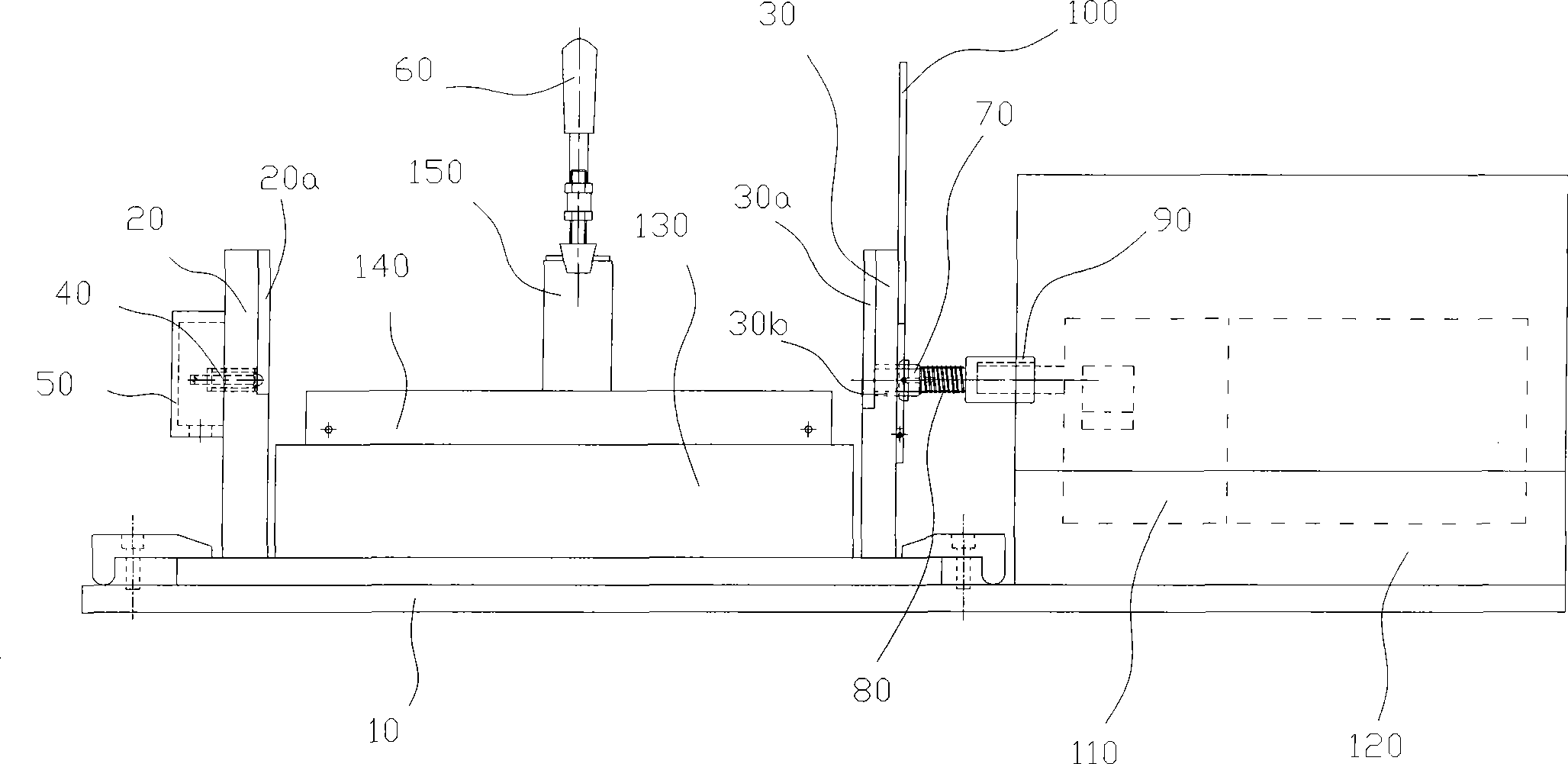

[0037] Such as image 3 As shown, a residual powder cleaning device is used to clean the toner on the toner box. The voltage supply section that supplies the voltage, the exposure section that exposes the photosensitive drum on the toner cartridge, the cleaning section that cleans the toner on the toner cartridge, and the toner cartridge support frame.

[0038] The powder box supporting frame includes a base 10 and a first side plate 20 and a second side plate 30 arranged at two ends of the base 10 matching the length of the powder box. The first side panel 20 and the second side panel 30 are installed on the base 10 and are perpendicular to the base 10 . The first side plate 20 and the second side plate 30 are respectively provided with grooves 20a, 30a, and the two ends of the powder box A are respectively supported by the grooves 20a, 30a on the first side plate 20 and the second side plate 30 , the distance between the grooves 20a, 30a on the first side plate 20 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com