Textile slurry composition mixed with starches of different denaturation degrees and preparation thereof

A technology of textile size and modified starch, which is applied in the field of textile size, can solve problems such as the inability to solve the contradiction between the viscosity of starch size and the strength of the size film, reduce the mechanical strength of starch, reduce the cost of size, increase the breaking strength and breaking work , the effect of reducing the apparent viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

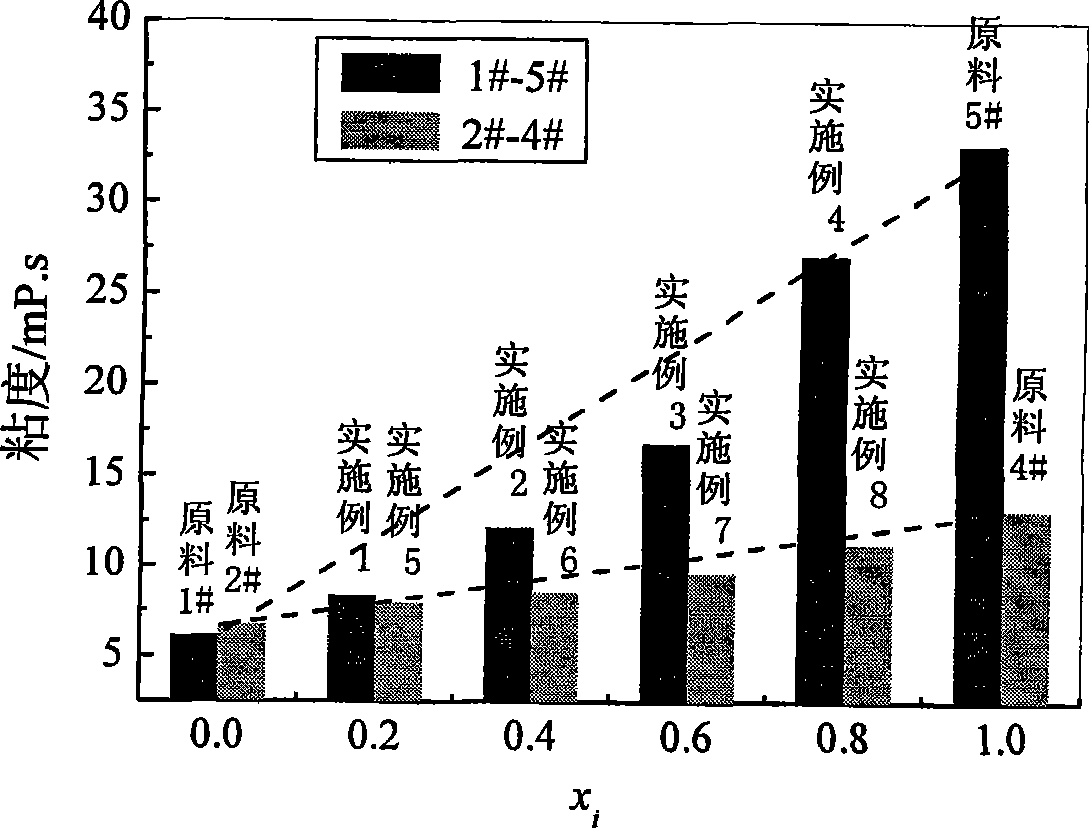

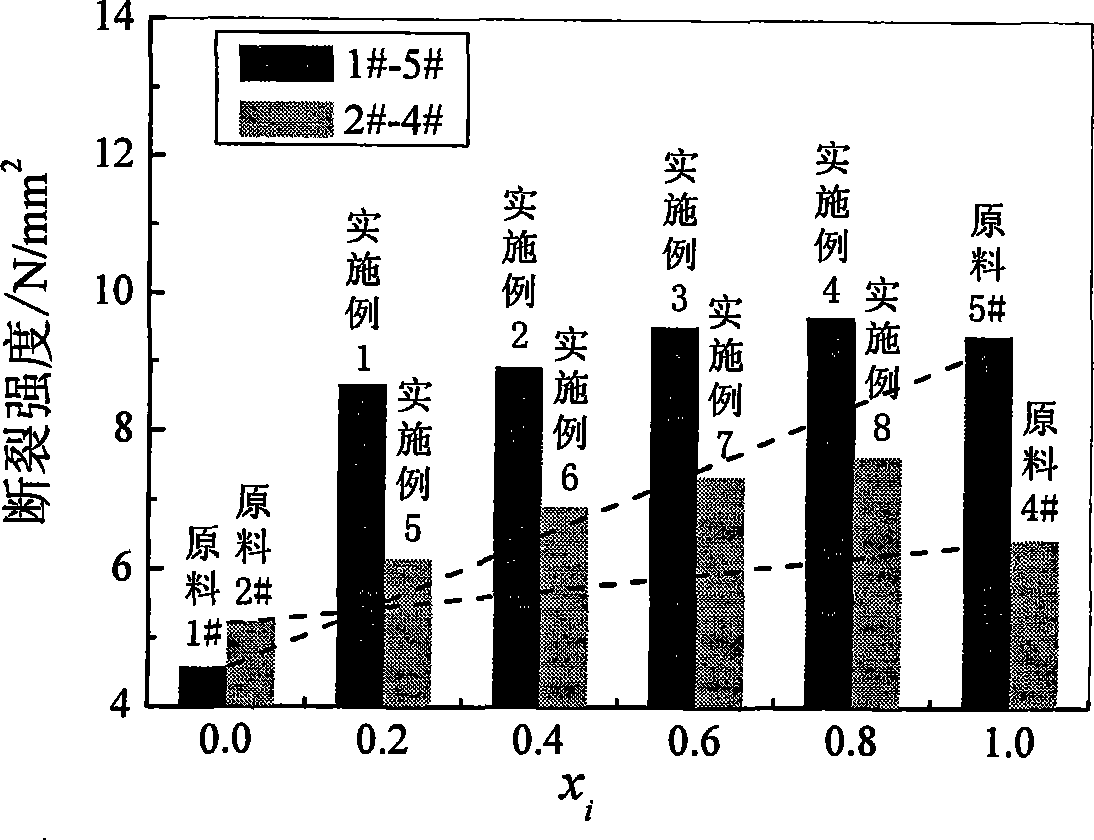

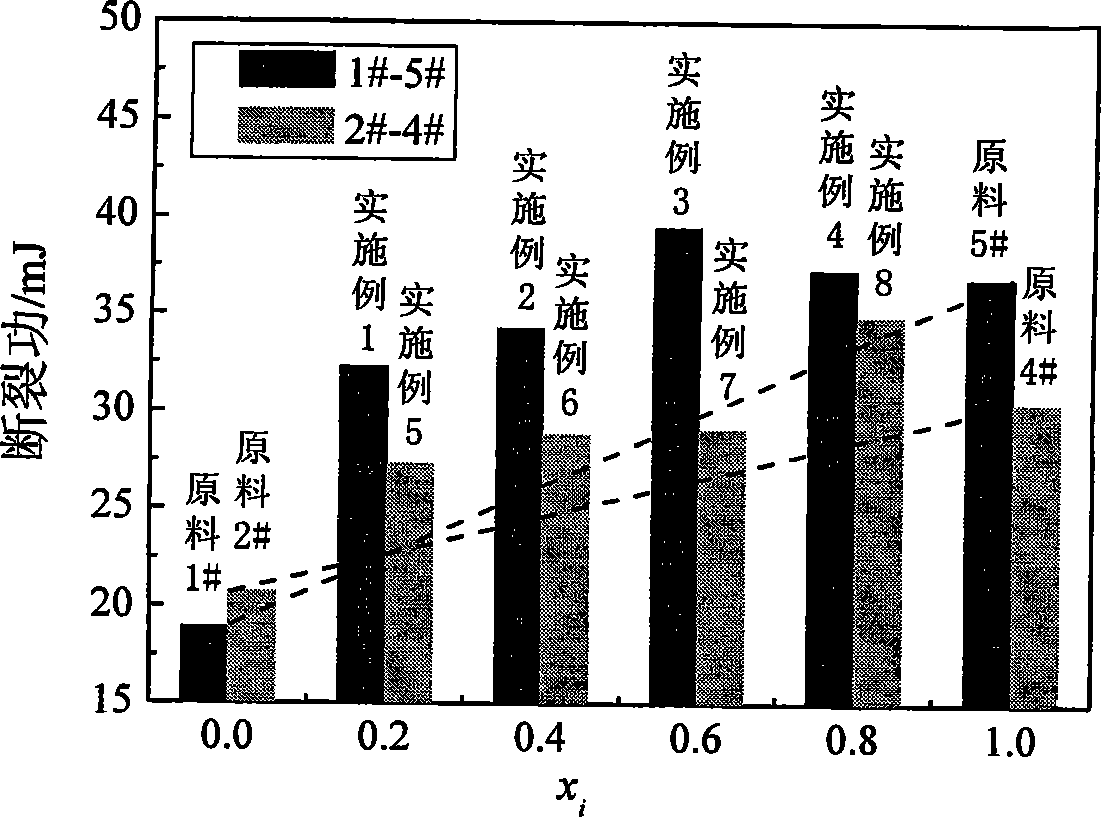

[0041] Take 8 parts of cassava acid-thinned starch 1# with a viscosity of 6.1mPa·s in Table 1, and take another 2 parts of cassava acid-thinned starch 5# with a viscosity of 33.2mPa·s, add them to the mixer, and perform physical Mix to obtain a slurry composition, and its viscosity and mechanical properties of the slurry film are measured according to the same test method as the raw materials, as shown in Table 2 for details.

Embodiment 2

[0043] Take 7 parts of cassava acid-thinned starch 1# with a viscosity of 6.1mPa·s in Table 1, and another 3 parts of local potato acid-thinned starch 5# with a viscosity of 33.2mPa·s, add them to the mixer, and carry out in a dry powder state. The slurry composition was obtained by physical mixing, and its viscosity and mechanical properties of the slurry film were measured according to the same test method as the raw materials, as shown in Table 2 for details.

Embodiment 3

[0045] Take 6 parts of cassava acid-thinned starch 1# with a viscosity of 6.1mPa·s in Table 1, and another 4 parts of cassava acid-thinned starch 5# with a viscosity of 33.2mPa·s, add them to the mixer, and perform physical Mix to obtain a slurry composition, and its viscosity and mechanical properties of the slurry film are measured according to the same test method as the raw materials, as shown in Table 2 for details.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com