High strength cold state asphalt fissure cementation water-proof glue and preparation thereof

A high-strength, waterproof adhesive technology, applied in chemical instruments and methods, other chemical processes, building components, etc., can solve problems such as unstable performance and quality, large cost differences, corrosion of equipment, etc., to achieve stable emulsification effect and reduce production costs Low, equipment does not corrode the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

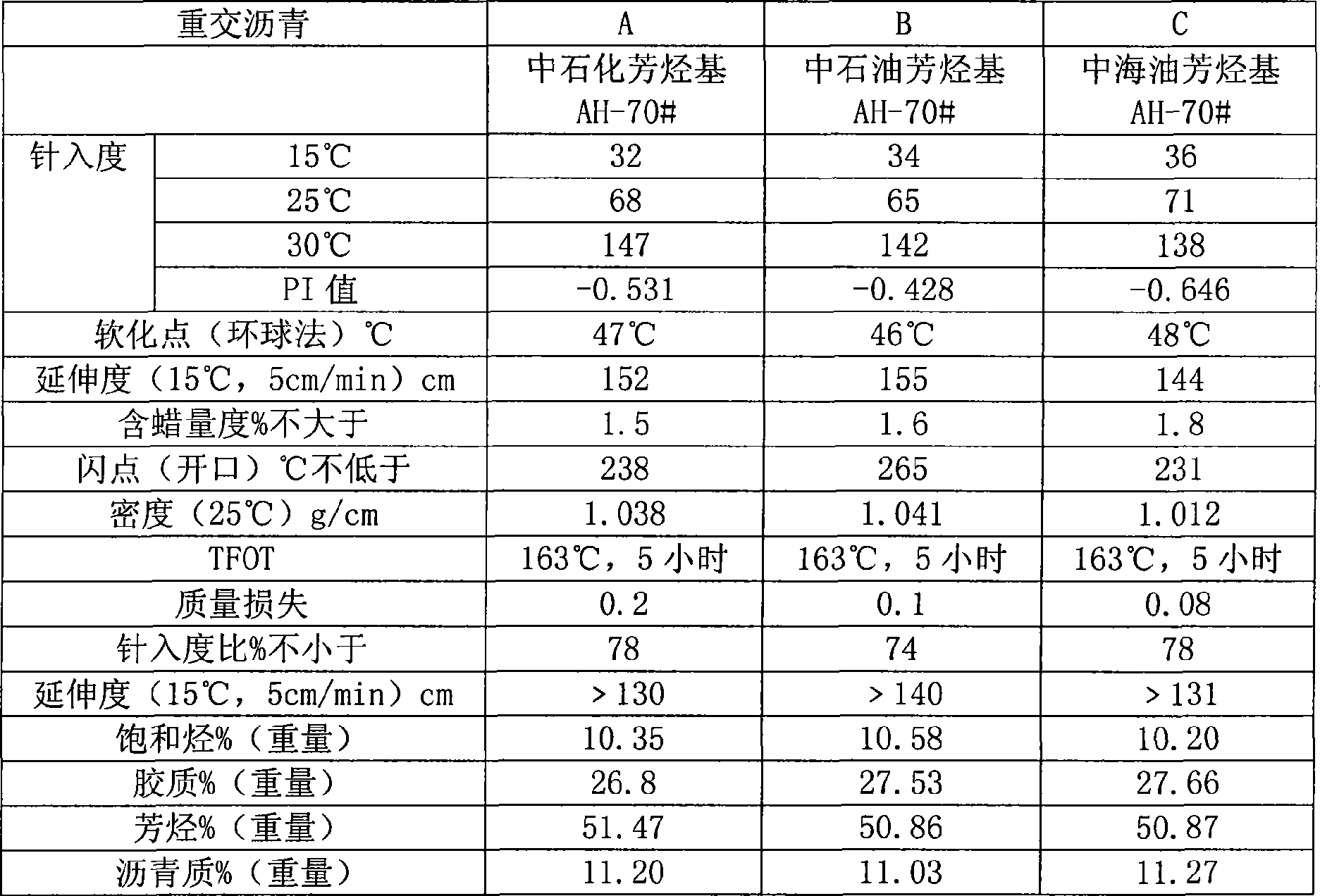

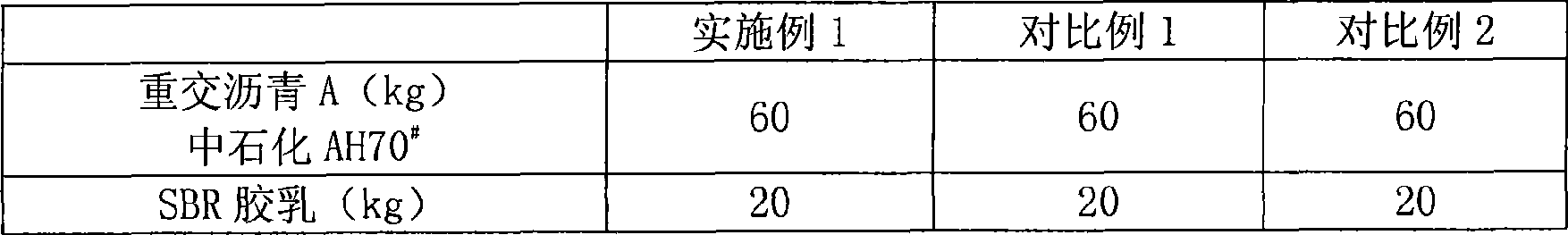

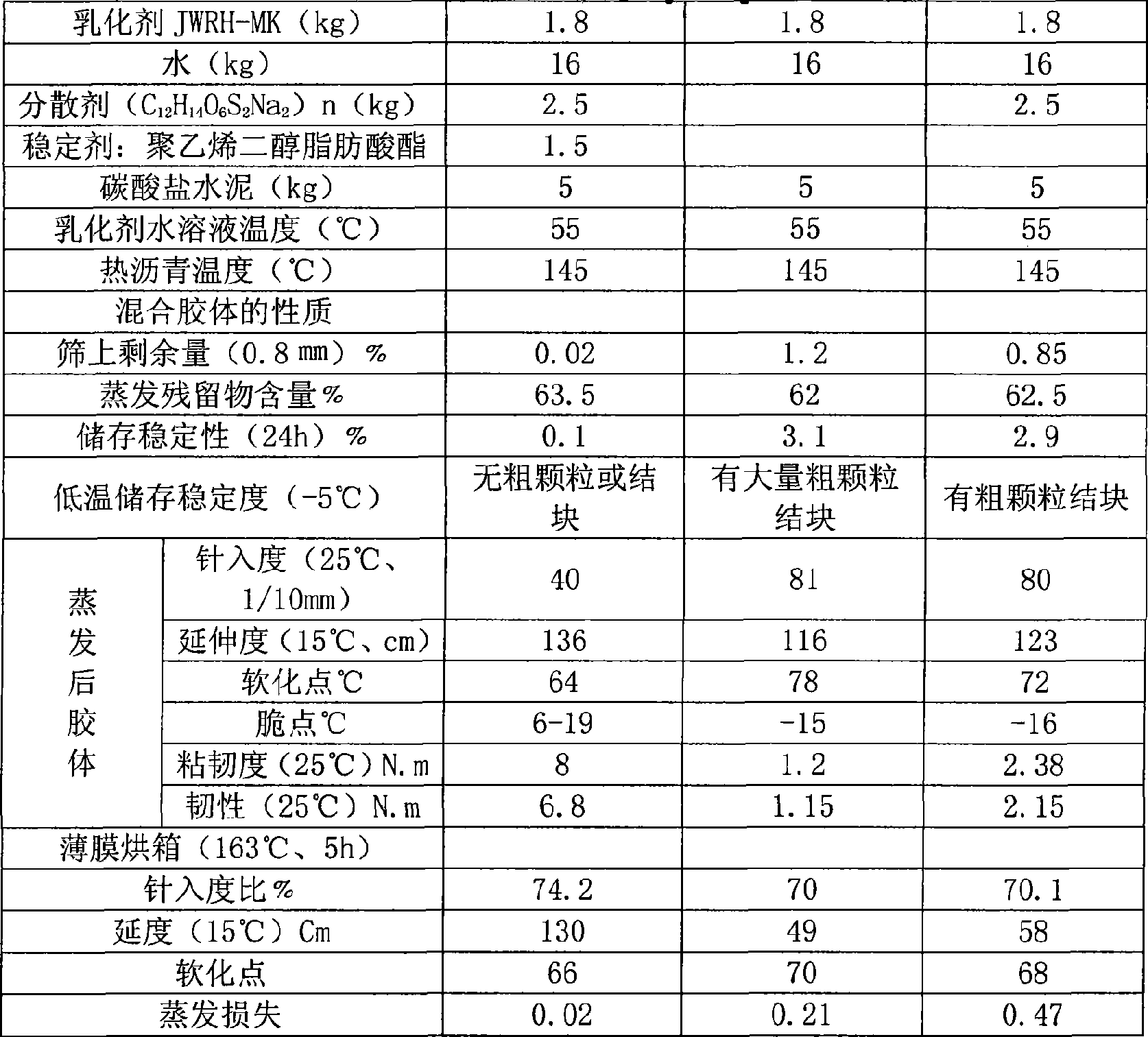

Embodiment 1

[0050] Take 16kg of clean water, add 1.8kg of slow-cracking and fast-setting cationic emulsifier (RC-SMRHJ804 Jiangyin Rongcheng Road and Bridge Company) in the water, add modifier polymer SBR latex 20kg, dispersant naphthalenesulfonic acid formaldehyde mixed sodium salt 2.5kg gram, polyethylene glycol fatty acid 1.5kg after stirring evenly, when the temperature reaches 65°C, continue to stir evenly and keep the temperature. Take 60kg of Sinopec aromatic hydrocarbon base AH-704# heavy traffic asphalt A, 5kg of carbonate cement and heat it to 165°C, stir them together and put them into a colloid mill for grinding at a speed of 6000 rpm. High-strength cold asphalt joint waterproofing glue. The test results show (see Table 2) that the various indicators are ideal, the amount left on the sieve is small, the storage stability is good, the softening point is high, the viscosity is good, and the aging performance is good.

Embodiment 2

[0059] Get 15kg clean water, add 1.5kg polyoxyethylene alkyl quaternary ammonium hydrochloric acid emulsifier, 1.8kg methyl bis-naphthalene sodium sulfonate (NNO), 1.0kg graft copolymerization of polyorganosiloxane and polyhydric alcohol in water stabilizer, stir evenly and heat to 65°C, then add 15kg (acrylonitrile-butadiene-styrene resin ABS) copolymer latex, mix well, keep warm for later use, and take 62kg heavy asphalt B, diatom 6kg of soil is heated to 160°C. After being heated evenly, it enters the colloid mill for grinding together with the prepared solution at the speed of 7000 rpm. After grinding for two minutes, a qualified high-strength cold asphalt joint waterproofing glue can be obtained. The analysis results show (see table 3), the viscosity of colloid, the residual amount on the sieve, and the evaporation residue content reach the specified standard, and the stability of the quasi village is only 0.06 in 24 hours, and the low temperature storage stability has no...

Embodiment 3

[0062] Get 15kg of clean water, add 2kg of RH-C05 amide cationic emulsifier successively, 2.6kg of sodium methylene bis-naphthalene sulfonate MF dispersant, 1.8kg of SaSobit (SaSobit) stabilizer, after stirring evenly, heat up to 65°C, then add 25kg, SBS latex polymer, continue to stir and mix evenly, keep the temperature for later use, and take 55kg of heavy traffic asphalt AH-70#c and heat it to 168°C. After being evenly heated, 10kg of light calcium carbonate is slowly added to the prepared solution and stirred evenly, and then ground in a colloid mill for 2 minutes at a speed of 8000 rpm to obtain a qualified high-strength cold-state asphalt joint waterproofing glue (its properties See Table 3). The colloid has high viscosity, good stability, no coarse particles and agglomerates in low temperature storage, high softening point, strong viscosity and toughness, which is beneficial to the maintenance of the joint glue cover. The original roadbed of Qianrong line in Wuxi urban...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com