Preparation of fireproofing foamed material

A foam material and mixture technology, applied in the direction of fire prevention, dust prevention, mining equipment, etc., can solve the problem of high construction requirements, and achieve the effects of low temperature requirements, low smoke density, and high oxygen index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

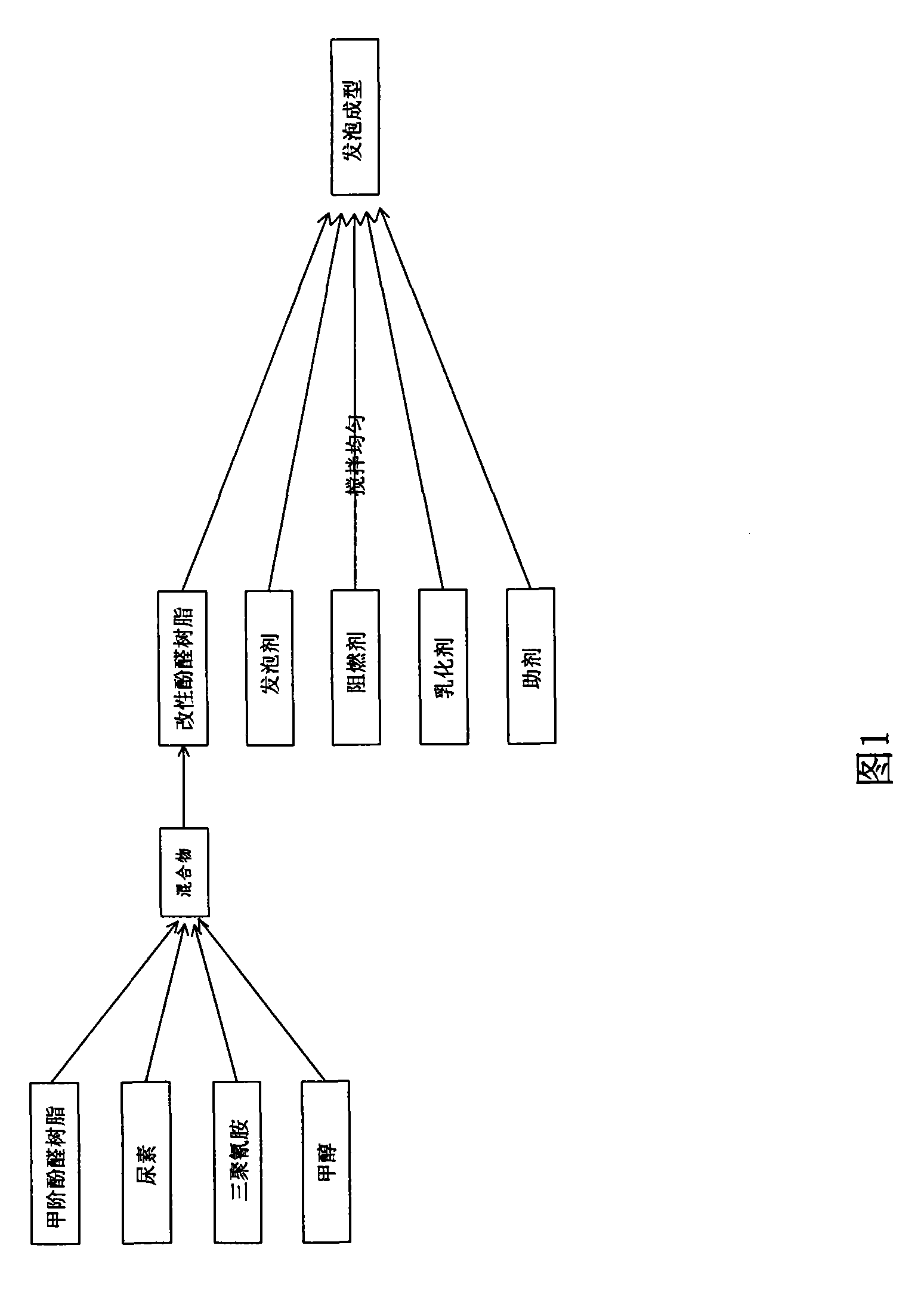

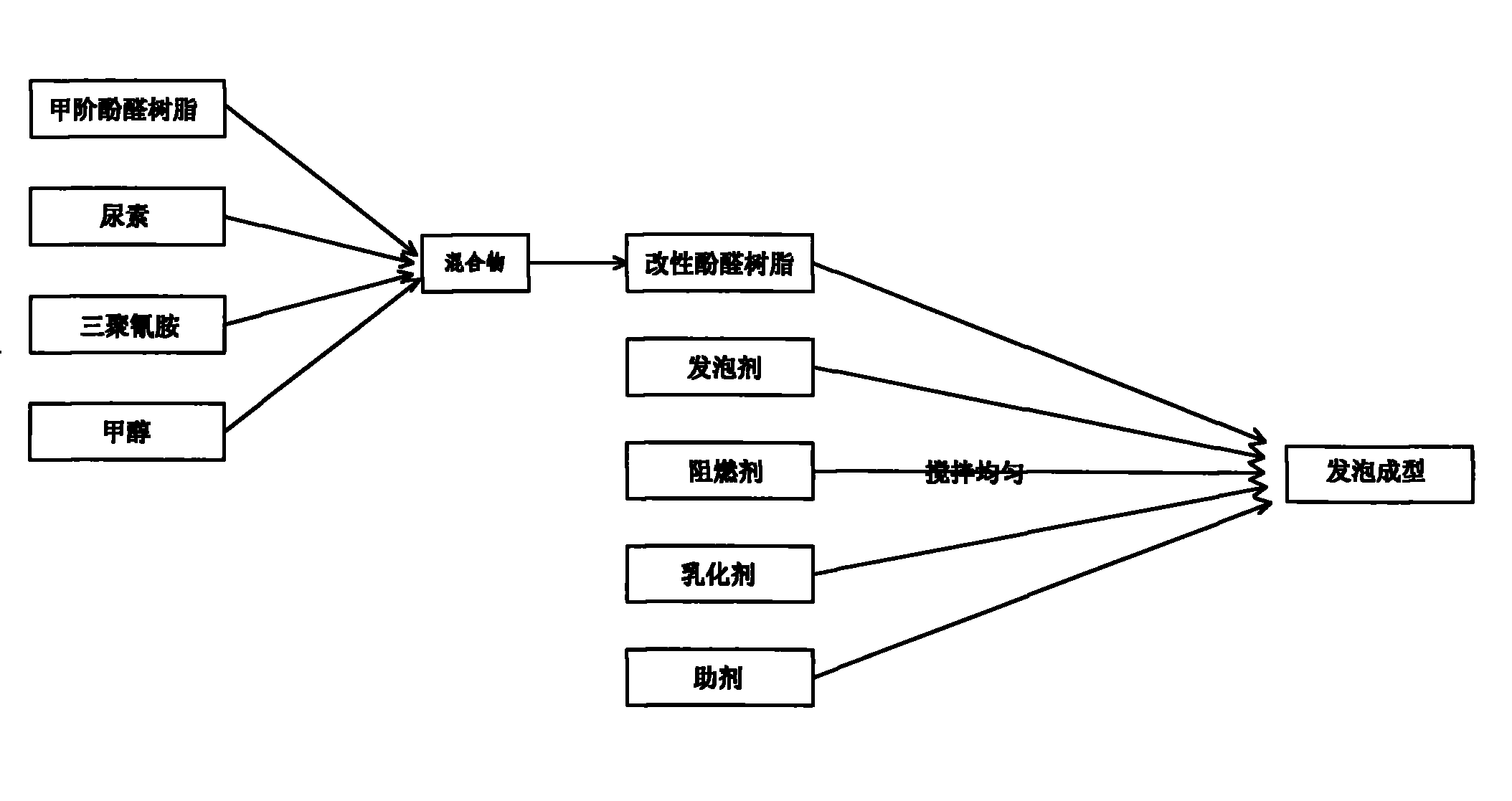

[0020] As shown in Figure 1, a kind of preparation method of fireproof foam material, its technological process is as follows:

[0021] 1. Mix resole phenolic resin, urea, melamine, fireproof polyether, and methanol to form the first mixture; the proportion of the first mixture is as follows in parts by weight: 100 parts of resole phenolic resin, 10 parts of urea, and 3 parts of melamine , 5 parts of fireproof polyether, 50 parts of methanol;

[0022] 2. Add alkali to the first mixture to form the second mixture; adjust the pH value of the second mixture to 8-9; then heat to make the reaction temperature between 60-90°C and react for 1-3 hours , stop heating;

[0023] 3. Neutralize the heated second mixture with acid so that its pH value reaches 6 to 7 to form a third mixture; then carry out vacuum demethanolization to the third mixture; then, at a temperature of 25°C Adjust the viscosity of the third mixture after demethanolization, so that the viscosity is 1000-3000mpa.s t...

example 2

[0033] As shown in Figure 1, a kind of preparation method of fireproof foam material, its technological process is as follows:

[0034] 1. Mix resole phenolic resin, urea, melamine, fireproof polyether, and methanol to form the first mixture; the proportion of the first mixture is as follows in parts by weight: 100 parts of resole phenolic resin, 15 parts of urea, and 5 parts of melamine , 7 parts of fireproof polyether, 65 parts of methanol;

[0035] 2. Add alkali to the first mixture to form the second mixture; adjust the pH value of the second mixture to 8-9; then heat to make the reaction temperature between 60-90°C and react for 1-3 hours , stop heating;

[0036] 3. Neutralize the heated second mixture with acid so that its pH value reaches 6 to 7 to form a third mixture; then carry out vacuum demethanolization to the third mixture; then, at a temperature of 25°C Adjust the viscosity of the third mixture after demethanolization, so that the viscosity is 1000-3000mpa.s t...

example 3

[0046] As shown in Figure 1, a kind of preparation method of fireproof foam material, its technological process is as follows:

[0047] 1. Mix resole phenolic resin, urea, melamine, fireproof polyether, and methanol to form the first mixture; the proportion of the first mixture is as follows in parts by weight: 100 parts of resole phenolic resin, 20 parts of urea, and 8 parts of melamine , 10 parts of fireproof polyether, 80 parts of methanol;

[0048] 2. Add alkali to the first mixture to form the second mixture; adjust the pH value of the second mixture to 8-9; then heat to make the reaction temperature between 60-90°C and react for 1-3 hours , stop heating;

[0049]3. Neutralize the heated second mixture with acid so that its pH value reaches 6 to 7 to form a third mixture; then carry out vacuum demethanolization to the third mixture; then, at a temperature of 25°C Adjust the viscosity of the third mixture after demethanolization, so that the viscosity is 1000-3000mpa.s t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com