Cold mixing high polymer modified asphalt concrete and preparing method thereof

A technology of polymer modification and asphalt concrete, which is applied in the direction of climate change adaptation, etc., can solve problems such as reflective cracks, large temperature difference between day and night, and road performance degradation, and achieve good low-temperature cracking resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

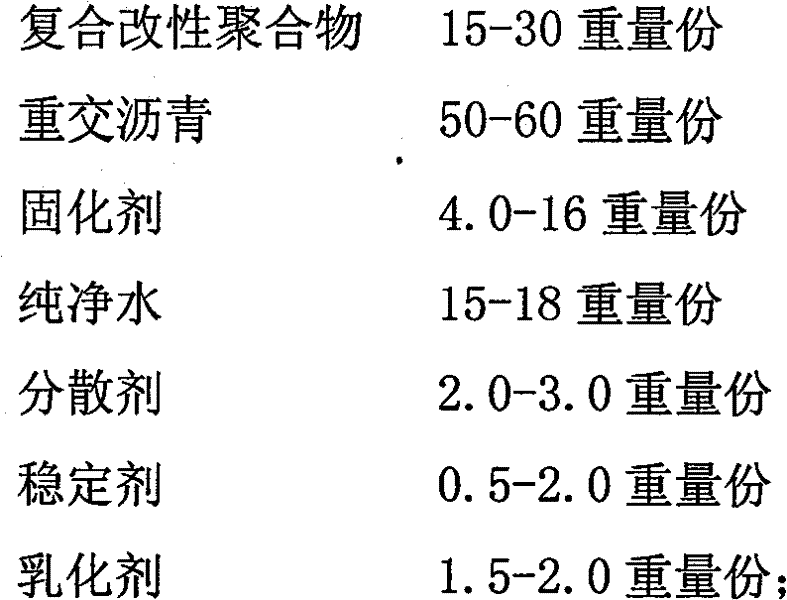

Embodiment 1

[0068] Take 16Kg of clean water, add 1.8Kg of slow-cracking and fast-setting cationic emulsifier (RC-SMRHJ804 Jiangyin Rongcheng Road and Bridge Company) in the water, add 20Kg of composite modified polymer SBR latex and 10Kg of natural latex (based on polymer weight) , 2.5Kg mixed sodium naphthalenesulfonic acid formaldehyde salt as dispersant, 1.5Kg polyethylene glycol fatty acid, after stirring evenly, continue to stir evenly and maintain the temperature when the temperature reaches 65°C. Take 60Kg of Sinopec aromatic hydrocarbon base AH-704# heavy traffic asphalt, 5kg of carbonate cement and heat it to 165°C, stir together evenly and add it to the colloid mill for grinding at a speed of 5000 rpm. After 5 minutes of processing, the cold state to be prepared will be obtained. High strength bitumen. The test results show (see Table 2-4) that the various indicators are ideal, the residual amount on the sieve is small, the storage stability is good, the softness is high, the vi...

Embodiment 2

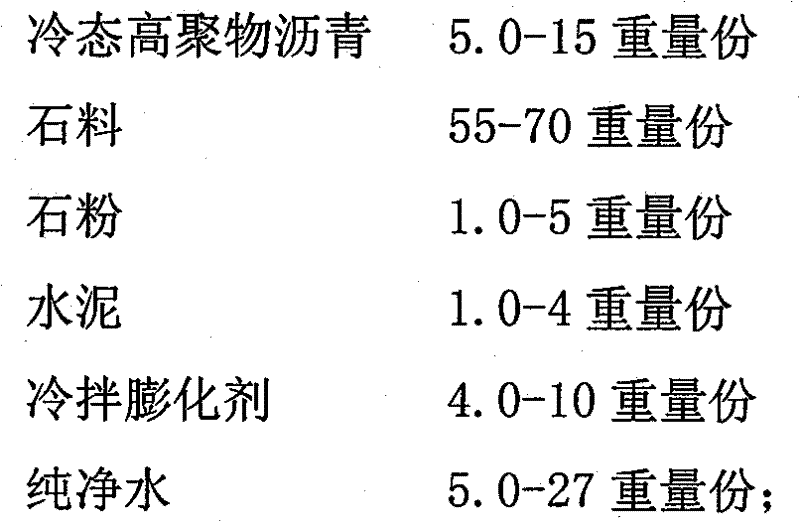

[0070] In this example, the cold high polymer asphalt produced by Jiangyin Rongcheng Road and Bridge Company is used. The stone material is basalt, cold mix expansion agent, No. 500 cement, and pure water are cold mixed to form cold mix high polymer modified asphalt concrete. The formula and performance are listed in Table 5 below:

[0071] table 5

[0072]

[0073]

Embodiment 3

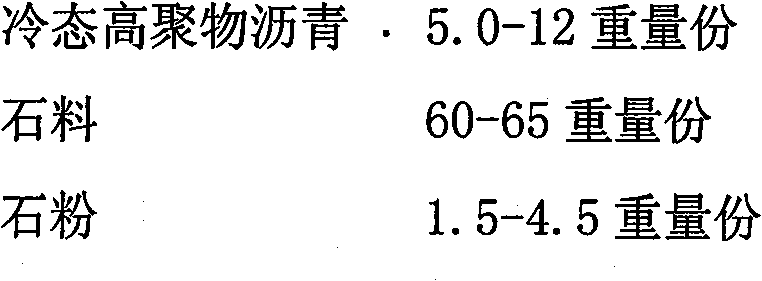

[0075] Embodiment 3 manufactures the same as embodiment 2, different adopting components and component parts by weight are shown in table 6

[0076] Table 6

[0077]

[0078]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com