A high-strength composite structural layer for anti-rutting and its preparation method

A composite structure, anti-rutting technology, applied in the direction of on-site coagulation pavement, roads, buildings, etc., can solve the problems affecting the quality and service life of asphalt pavement structure, the improvement effect of anti-rutting deformation ability is limited, and the optimization effect is not effective. Significant problems such as high resistance to permanent deformation and waterproofing, good water seepage coefficient, and improved paving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

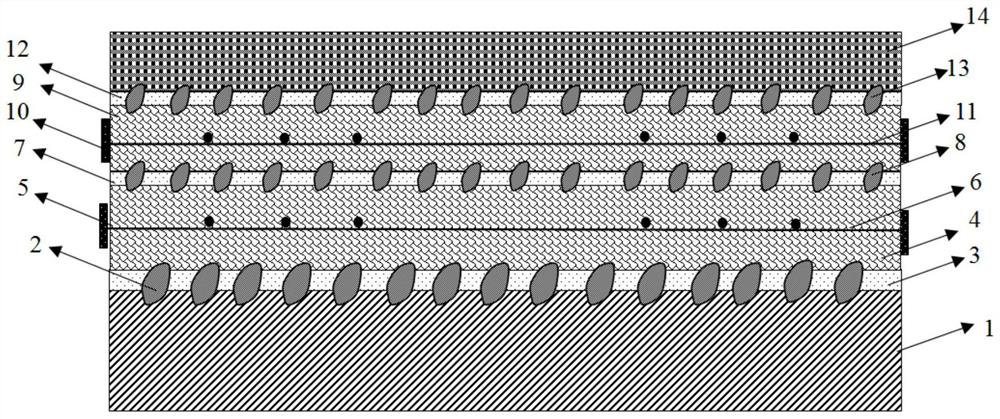

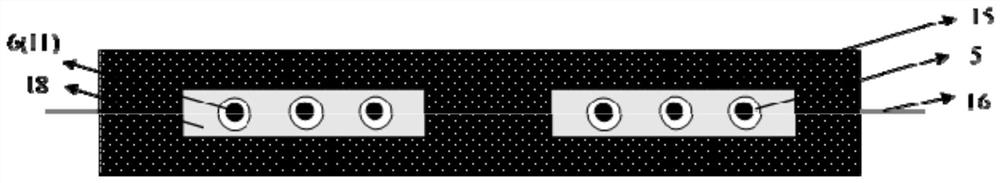

[0043] Such as figure 1 As shown, a high-strength composite structural layer for anti-rutting in this embodiment includes a lower high-ductility MMA resin exposed rock layer, a lower reinforced structural layer 4, and a middle layer with high strength Type MMA resin graded crushed stone layer, middle reinforced reinforced structure layer 9, upper high strength MMA resin graded crushed stone layer, upper wearing layer 14; the lower high ductility MMA resin dew stone layer includes lower high ductility MMA resin bonded The knot layer 3 and exposed rock layer 2, the lower high-ductility MMA resin bonding layer 3 is laid on the exposed rock layer 2, the exposed rock layer 2 is embedded in the lower high-ductility MMA resin bonding layer 3, and contacts the lower reinforced structural layer 4; the middle-level high-strength MMA resin graded crushed stone layer includes a middle-level high-strength MMA resin bonding layer 7 and a middle-level graded crushed stone layer 8, and the mi...

Embodiment 2

[0091] The high-strength composite structure for anti-rutting used in Example 2, except that the amount of MMA resin binder and the amount of graded crushed stone in the interlayer bonding system is different from that of Example 1, the preparation and paving methods of the rest of the materials are the same as those of Example 1. Same.

[0092] The high-ductility MMA resin bonding material adopted in the lower high-ductility type MMA resin bonding layer 3 has a sprinkling amount of 0.8kg / m 2 The high-strength MMA resin bonding material adopted by the middle layer high-strength MMA resin bonding layer 7 and the upper layer high-strength MMA resin bonding layer 12, the spreading amount is respectively 0.5kg / m 2 , the spreading amount of the upper high-strength MMA resin bonding layer 12 is 0.7kg / m 2 .

[0093] Both the middle graded crushed stone and the upper graded crushed stone are made of limestone, the shape of the limestone is similar to a cube, and it has high compress...

Embodiment 3

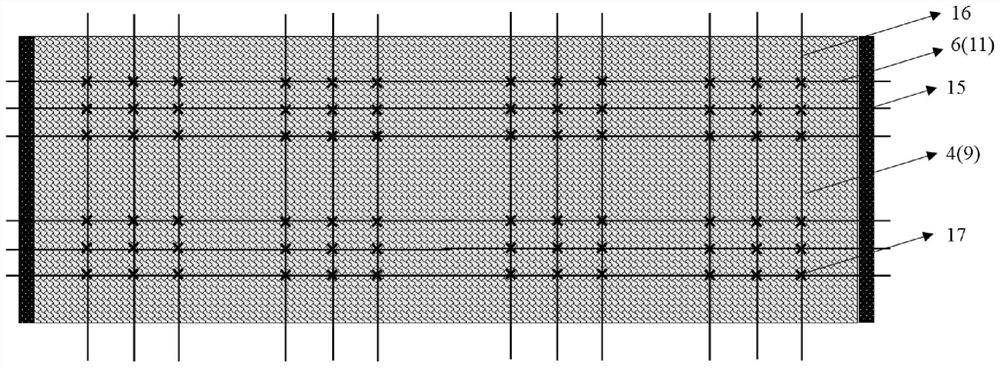

[0095] In the high-strength composite structure for anti-rutting used in Example 3, except that the structure thickness of the lower reinforced structural layer 4 and the middle reinforced structural layer 9, and the layout density of the high-strength and high-modulus fiber reinforced mesh are different from those in Example 1, the rest of the materials are The preparation and paving method are all the same as example 1.

[0096] The structural thicknesses of the lower reinforced structural layer 4 and the middle reinforced structural layer 9 are 50mm and 30mm respectively; A group of 8 high-modulus fiber bundles, the distance within a group is 40mm, the distance between groups is 100mm, and the lap length is 320mm; along the driving direction, a group of 10 high-strength and high-modulus fiber bundles, the distance between high-strength and high-modulus fiber bundles within a group is 50mm , the spacing between groups is 100mm, the lap length is 500mm, and the fibers of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com