Two-component polyaspartate urea rigid adhesive and its use and application

A technology of aspartic acid ester and tetraethyl aspartic acid ester, applied in the direction of polyurea/polyurethane adhesive, adhesive, adhesive type, etc., can solve the problems of strict construction requirements, poor construction performance, and low construction efficiency , to achieve good UV aging resistance, resistance to sunlight, and firm bonding of aggregates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1 This example discloses a two-component polyaspartate urea rigid adhesive, the adhesive components are as follows:

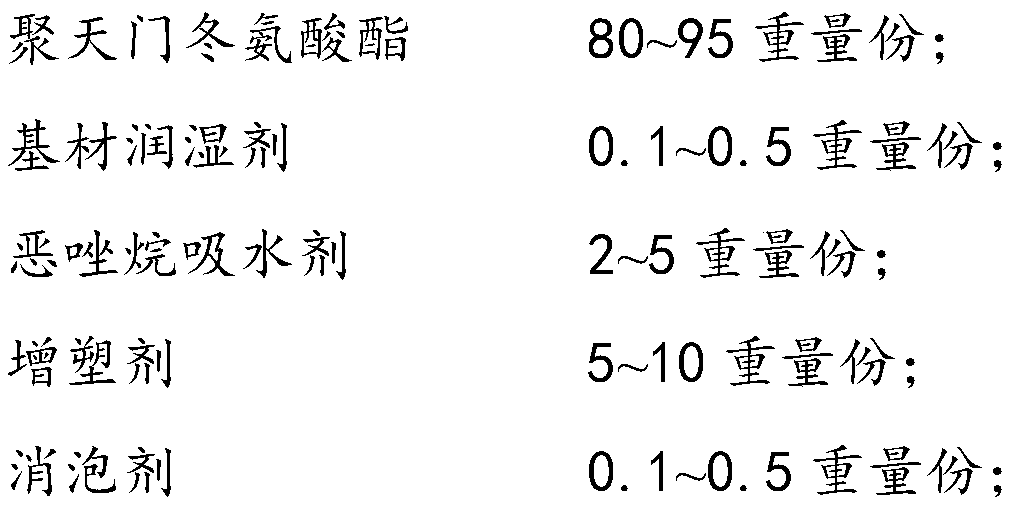

[0025] A component formula:

[0026] 90.2 parts by weight of N,N'-(methylene di-4,1-cyclohexanediyl) diaspartic acid tetraethyl ester;

[0027]

[0028]

[0029] Component B is equal to component A, including trimer curing agent Bayer 3900, HMDI modified curing agent and IPDI modified curing agent, and the weight ratio of the three is 22:38:40.

[0030] Among them, the HMDI modified curing agent is synthesized by adding 100g of HMDI, dropwise adding 75g of PCL500, controlling the temperature at 80°C for 4hrs, then raising the temperature to 90°C for 4hrs, and detecting the NCO content: 11.1% and discharging.

[0031] The IPDI modified curing agent is 100g of IPDI, and 225g of PPG1000 is added dropwise to react until the NCO content is 5.8%.

[0032] This embodiment also discloses the use method of the two-component polyaspartic ester urea...

Embodiment 2

[0034] Example 2 This example discloses a two-component polyaspartate urea rigid adhesive, the adhesive components are as follows:

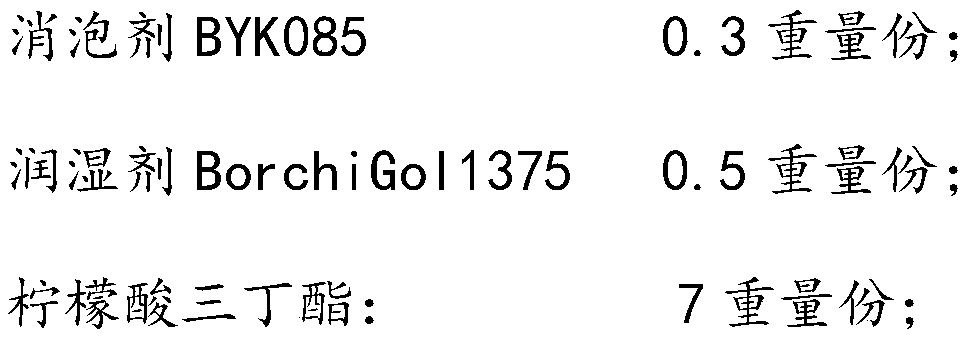

[0035] A component formula:

[0036] 90.2 parts by weight of N,N'-(methylene di-4,1-cyclohexanediyl) diaspartic acid tetrabutyl ester;

[0037]

[0038] Component B is equal to component A, including trimer curing agent Bayer 3900 and HMDI modified curing agent, the weight ratio of the two is 22:78;

[0039] The HMDI modified curing agent is synthesized by adding 100g of HMDI dropwise with 100g of PPG2000 and 60g of PPG400 under temperature control until the NCO content is 6.2%.

[0040] This embodiment also discloses the use method of the two-component polyaspartic ester urea rigid adhesive, and the steps of the method are as follows: mix the A component and the B component according to the corresponding parts by weight Stir evenly, trowel and apply on the asphalt surface with a thickness of 1-1.5mm, then quickly spread the wear-resistant a...

Embodiment 3

[0042] Example 3 This example discloses a two-component polyaspartate urea rigid adhesive, the adhesive components are as follows:

[0043] A component formula:

[0044] 80 parts by weight of N,N'-(methylene bis-(1-methyl,-4,1-cyclohexanediyl)) diaspartic acid tetraethyl ester;

[0045]

[0046] The same amount of component B and component A, including trimer curing agent Bayer 3900 and HMDI modified curing agent, the weight ratio of the two is 10:90;

[0047] The HMDI modified curing agent is synthesized by adding 100g of HMDI dropwise with 100g of PPG2000 and 60g of PPG400 under temperature control until the NCO content is 15%.

[0048] This embodiment also discloses the use method of the two-component polyaspartic ester urea rigid adhesive, and the steps of the method are as follows: mix the A component and the B component according to the corresponding parts by weight Stir evenly, trowel and apply on the asphalt surface with a thickness of 1-1.5mm, then quickly spread...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com