Method for flotation of potassium chloride from potassium salt mine

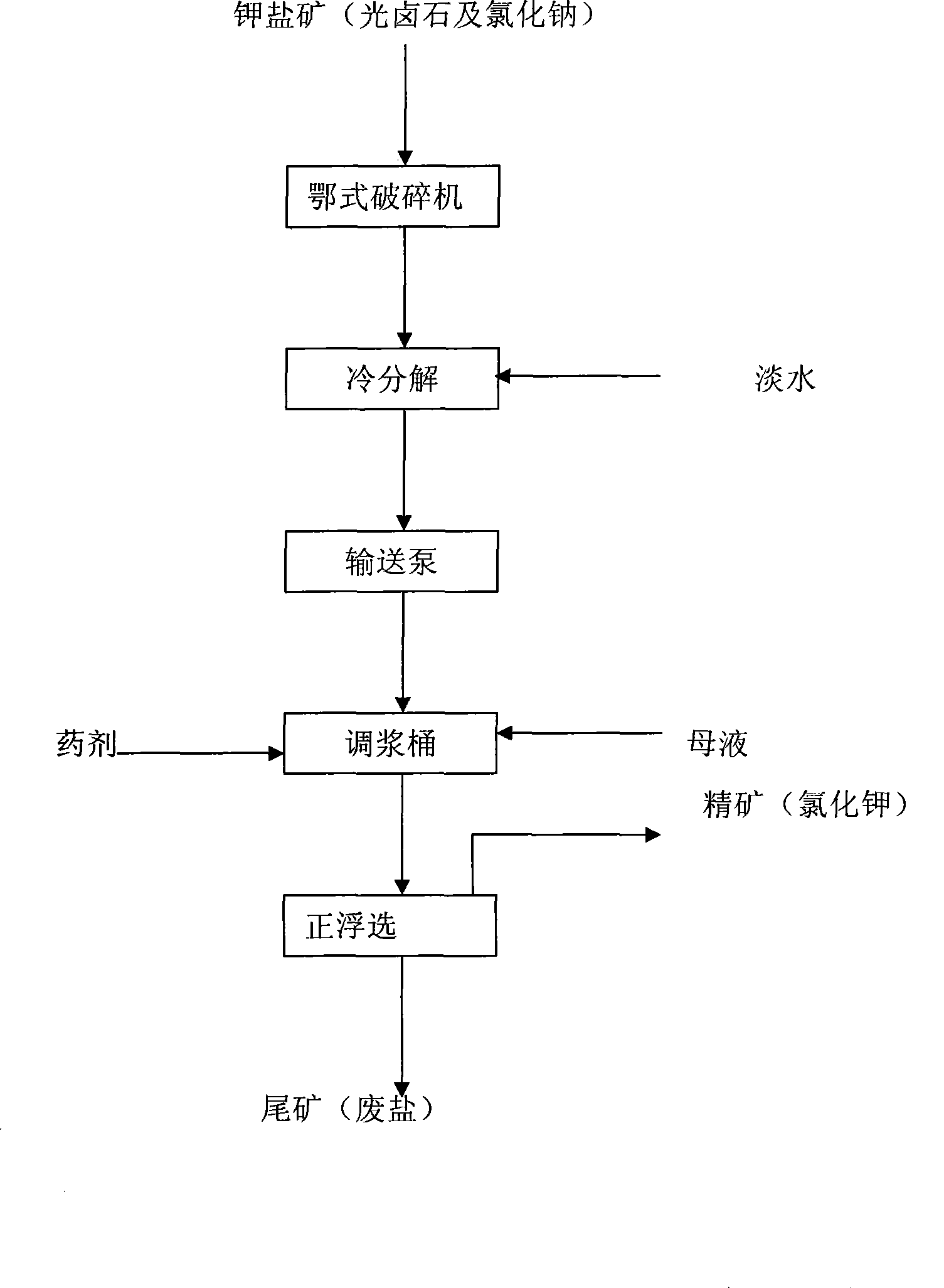

A technology for potassium chloride and potassium salt mines, applied in flotation, solid separation and other directions, can solve the problems of unfavorable flotation process promotion, complex production process, large total equipment investment, etc., and achieves good flotation effect and simple process. Stable, less circulating ore effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In the Chaerhan Saltfield Mine, the potassium content in the potash mine is 5.63%, and the magnesium content is 7.22%. Positive flotation process is adopted: the crushed ore particle size ranges from 3 to 8 mm, and fresh water is added for cold decomposition. Theoretical value of the fresh water addition amount of magnesium chloride, then adding fresh water cold decomposition, magnesium chloride is dissolved in water, the solid phase composition is potassium chloride and sodium chloride, and the flotation temperature is normal temperature. Introduce the ore pulp into the mineralization tank, add the saturated mother liquor of potassium chloride, sodium chloride and magnesium chloride, and add the positive flotation agent and mix thoroughly. The positive flotation agent is 1% octadecylamine hydrochloride, and the dosage is 2 %. The slurry concentration is 40%. The slurry is introduced into the flotation separation device. The flotation separation device is a micro-bubbl...

Embodiment 2

[0029] Laos solid potash mine, the potassium content in the potash mine is 8.4%, and the magnesium content is 5.13%. The positive flotation process is adopted, and the particle size of the crushed ore ranges from 3 to 8mm. The content of magnesium chloride in the raw ore was obtained by laboratory tests, and compared with the phase diagram of the quaternary water-salt system, the theoretical value of the amount of fresh water added just to dissolve magnesium chloride was calculated, and then fresh water was added for cold decomposition, magnesium chloride was dissolved in water, and the solid phase composition was potassium chloride and Sodium chloride, the flotation temperature is normal temperature. Introduce the ore pulp into the mineralization tank, add the saturated mother liquor of potassium chloride, sodium chloride and magnesium chloride, and add the positive flotation agent and mix thoroughly. The positive flotation agent is 1% octadecylamine hydrochloride, and the dos...

Embodiment 3

[0031]Laos solid potash mine, the potassium content of the potash mine is 8.1%, and the magnesium content is 4.83%. The positive flotation process is adopted, and the particle size of the crushed ore ranges from 3 to 8mm. The amount of fresh water added for cold decomposition is based on the sampling of the potash mine The content of magnesium chloride in the raw ore was obtained by laboratory tests, and compared with the phase diagram of the quaternary water-salt system, the theoretical value of the amount of fresh water added just to dissolve magnesium chloride was calculated, and then fresh water was added for cold decomposition, magnesium chloride was dissolved in water, and the solid phase composition was potassium chloride and Sodium chloride, the flotation temperature is normal temperature. Introduce the ore pulp into the mineralization tank, add the saturated mother liquor of potassium chloride, sodium chloride and magnesium chloride, and add the positive flotation agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com