Electroplating device and method

A technology of electrolytic coating and electrolyte solution, which is applied in the direction of contact devices, electrolytic processes, electrolytic components, etc., and can solve problems such as long devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

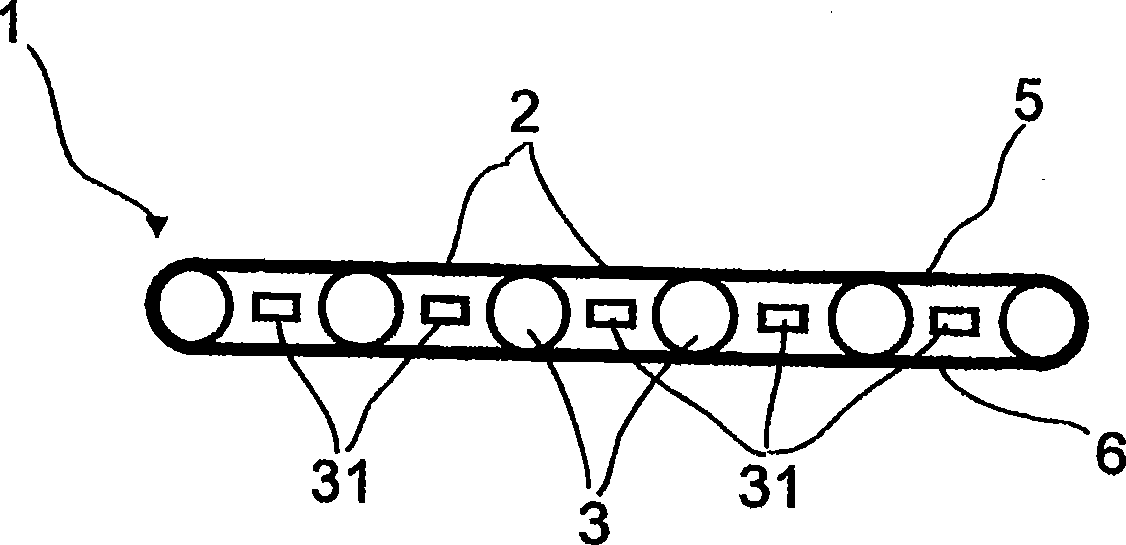

[0072] figure 1 Shown is a top view of a cathode designed according to the present invention, wherein multiple strips are biased in series.

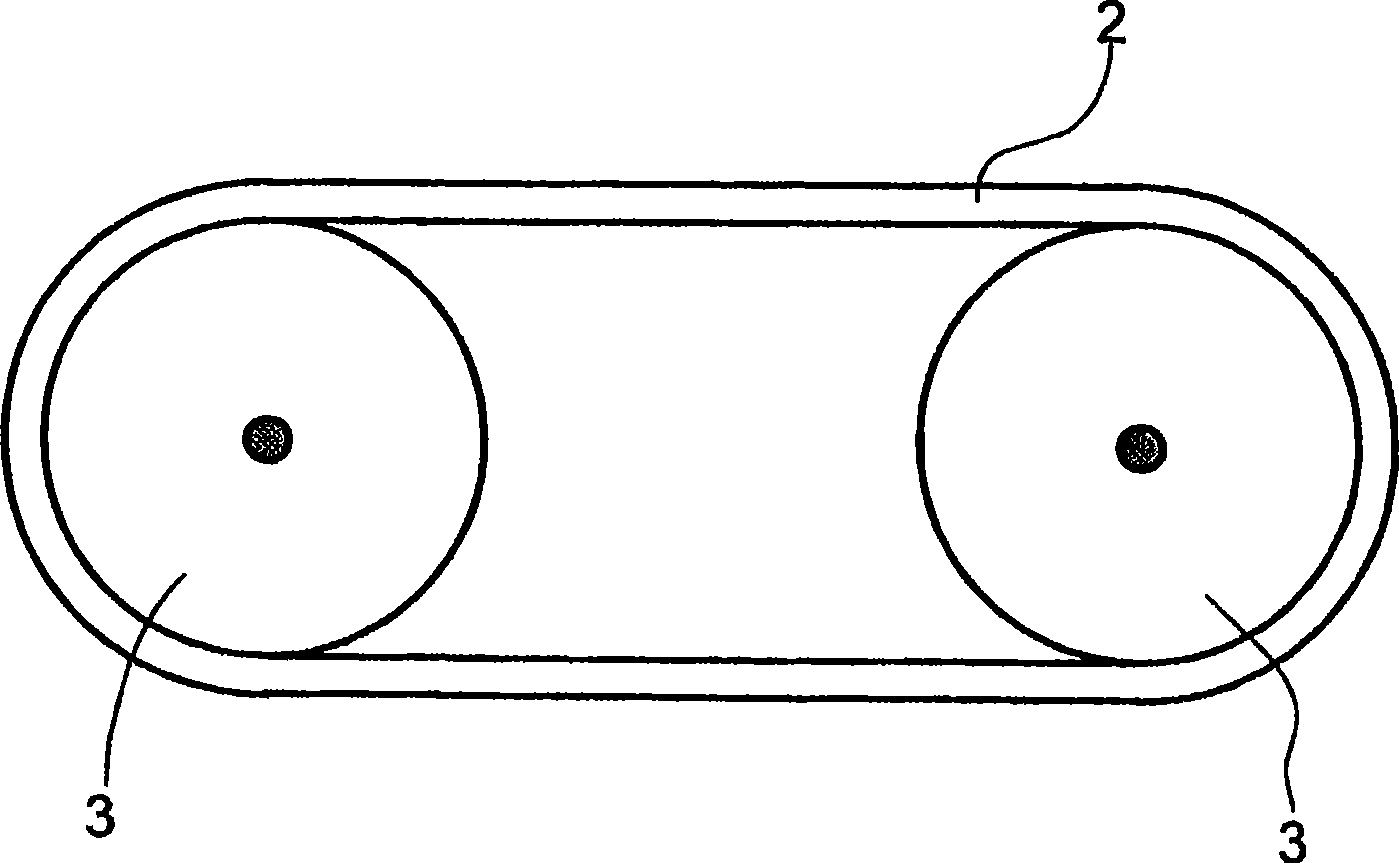

[0073] The cathode 1 comprises a plurality of strips 2 each guided by two shafts 3 . In this case, strips 2 adjacent to each other are arranged so as to form a gap 4 between them. The width of the gap 4 is in this case preferably greater than or equal to the width of the strip 2 . In this way, a strip 2 offset behind a certain row of strips 2 can be guided through the gap. exist figure 1 In the illustrated embodiment, one shaft 3 is used in this case as the rear shaft 3 of the straps 2 of the first row and the front shaft 3 of the straps 2 of the second row, respectively. Axes and space can be saved in this way compared to configurations in which the strips, offset behind a certain row, are guided about two separate axes. exist figure 1 In the exemplary embodiment shown, the coating process takes place in the gaps 4 between the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com