Single-phase connection method of ore furnace secondary low-voltage compensation device system

A connection method and low-voltage technology, applied in the direction of electric heating devices, harmonic reduction devices, reactive power compensation, etc., can solve the problems of smelting system voltage, current waveform distortion, increased line loss and electric furnace equipment loss, transformer temperature rise, etc., to achieve Improve operational reliability, improve unbalanced conditions, and eliminate surge current effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Figure 4 ~ Figure 6 Embodiment of electrical connection for secondary low voltage reactive power compensation of submerged arc furnace of the present invention

[0045] Below in conjunction with accompanying drawing, content of the present invention will be further described:

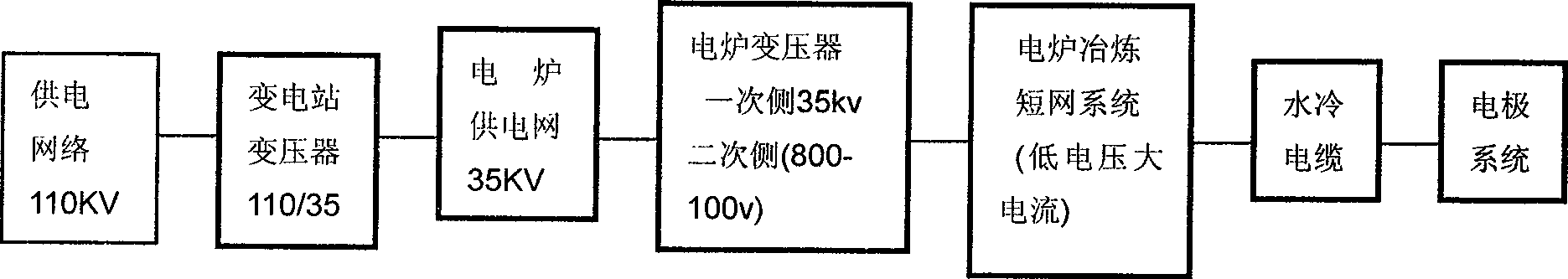

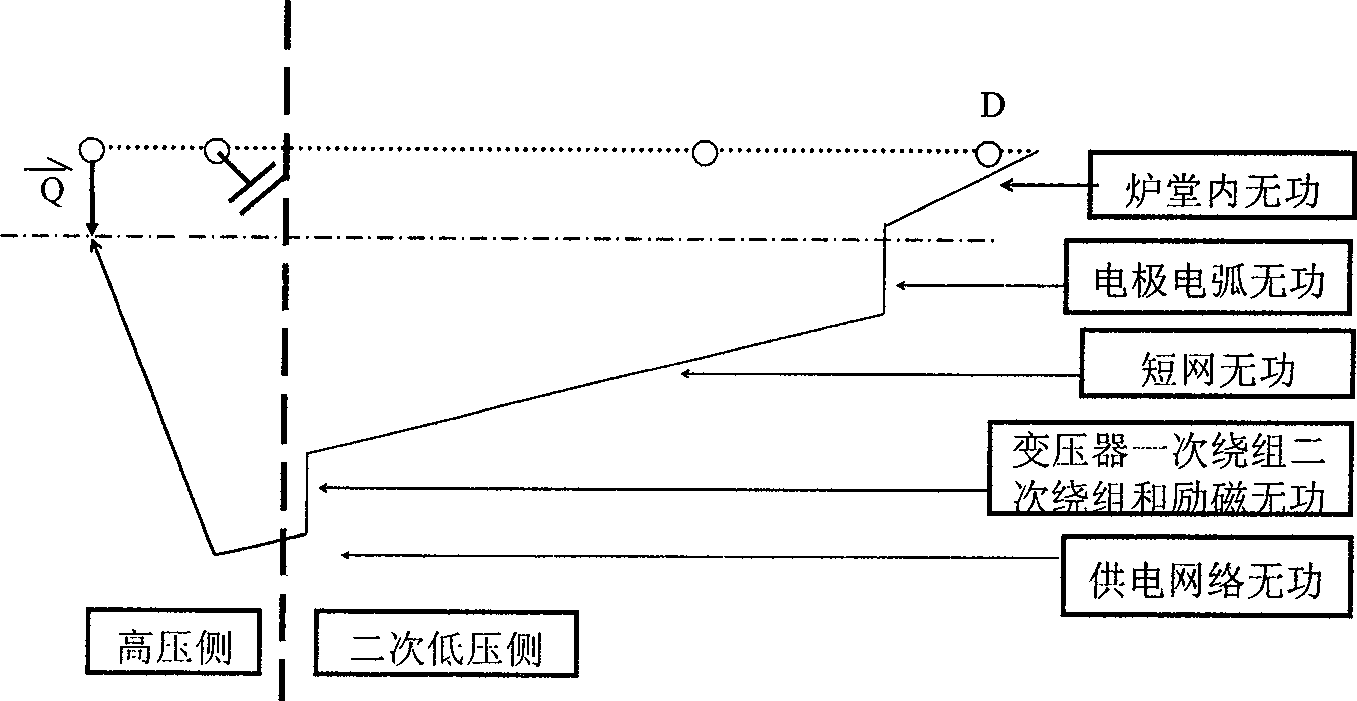

[0046] refer to Figure 4 As shown, the electrical system of electric furnace smelting is connected in sequence by high-voltage power supply network 1, substation transformer 2, electric furnace primary side power supply network 3, electric furnace transformer 4, electric furnace secondary side short network 5, water cooling cable 6, electrode 7 and furnace 8 The composition also includes that the two ends of the short network 5 on the secondary side of the electric furnace are connected in parallel with compensation capacitors 9 and 10.

[0047] Figure 5 shown, follow the steps below:

[0048] a. The 110kv high-voltage grid 1 is directly connected to the high-voltage primary side of the furn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com