Low-pressure gauge used for hazardous gas security measurement

A dangerous gas, low-pressure technology, applied in the field of low-pressure gauges, can solve problems such as open flames, explosions, and product insulation performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

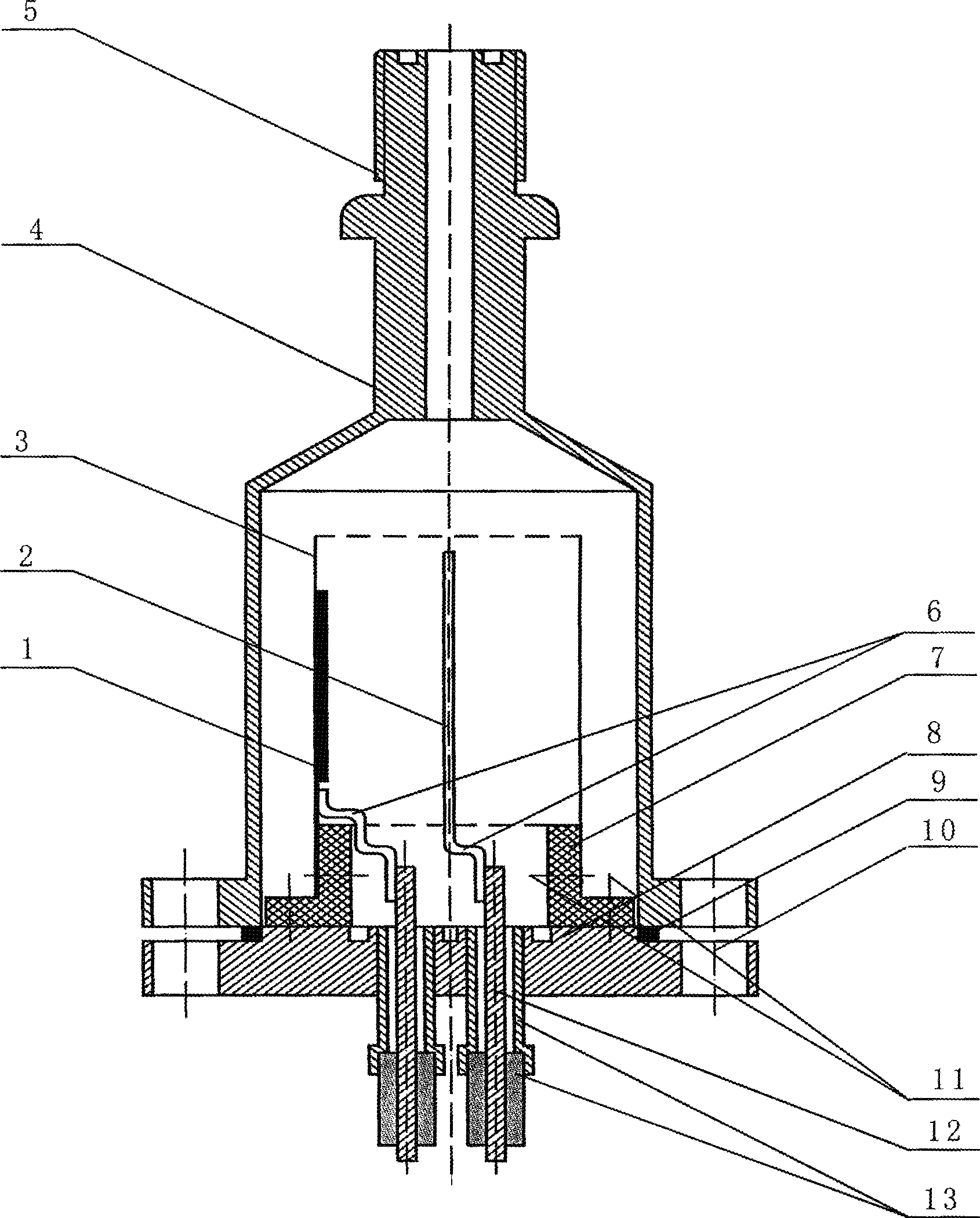

[0012] like figure 1 Shown, is the product structure schematic diagram of the present invention, and it is made of radioactive source (1), collecting pole (2), accelerating pole (3), shell (4), end cap (5), stainless steel sheet (6), insulating seat (7), flange seat (8), metal indium wire sealing ring (9), connecting bolt (10), connecting screw (11), ceramic lead wire (12) and electrode assembly (13). When the product is working, the β particles generated by the radioactive source (1) ionize the measured gas in the space of the accelerating pole (3). An electric field space is formed between the poles (2), under the action of the electric field force, the positive ions generated by ionization can move to the collector pole (2) in a directional manner, and are collected by the collector pole (2), forming a microampere-level weak current signal. The weak current signal has a linear relationship with the pressure of the measured environment in the low vacuum range. Therefore, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com