Plate-type non-return valve

A one-way valve and plate-type technology, which is applied in the field of hydraulic control valves, can solve problems such as the failure to meet the opening pressure requirements, the opening position of the poppet valve is not large enough, and the service life of the spring is shortened, so as to increase the fit clearance, prevent oil trapping, and use The effect of increasing lifespan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

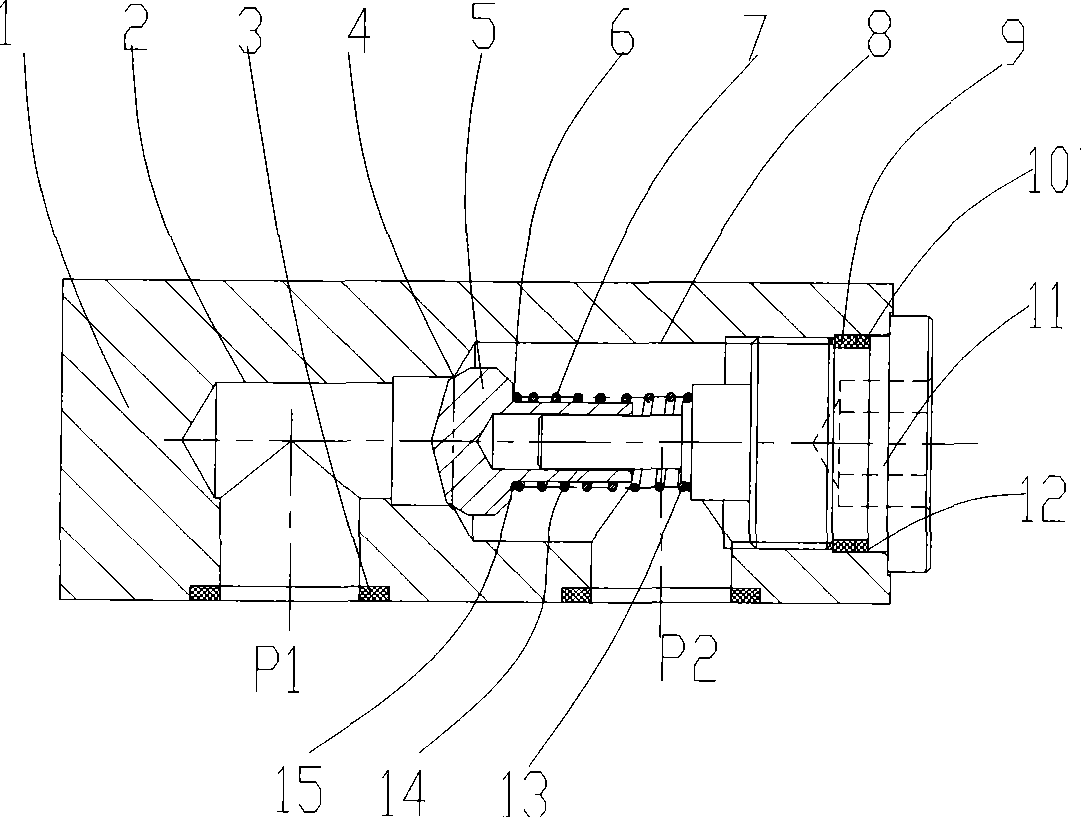

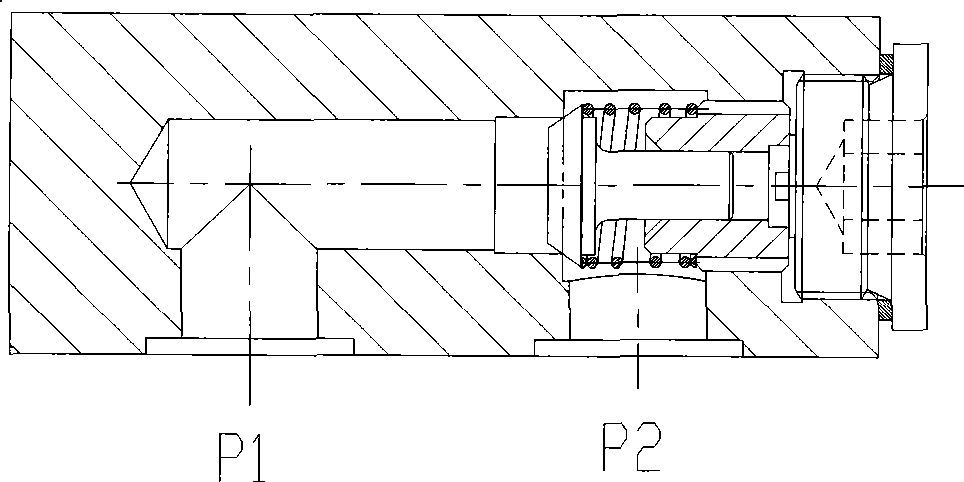

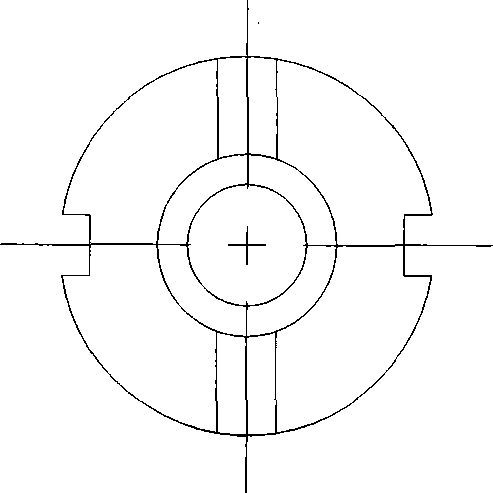

[0023] Such as figure 1 shown for explanation. When the hydraulic oil flows in from the P1 port and flows out from the P2 port. The plate check valve shown in the figure is in the closed state. As the oil flow increases, the oil overcomes the opening pressure of the spring 7 to move the cone valve 5 to the right on the left end guide surface of the end cover 11. At this time, the two chambers of P1 and P2 communicate. , the oil flows out from the P2 port. When the left end face of the end cover 11 is in contact with the inner hole wall of the poppet valve 5, the poppet valve 5 stops moving. 5 moves to the left and closes until the oil sealing surface 4 of the cone valve 5 contacts the oil sealing port of the valve body 1 to realize positive fluidity.

[0024] When the pressure oil enters from the P2 cavity, the pressure oil enters the spring cavity and acts on the shoulder and head of the cone valve 5, the cone valve 5 remains on the oil sealing surface 4, and no oil flows...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com