Fixing device of filter disk filter cloth

A fixed device and filter technology, which is applied in the direction of mobile filter element filter, filter separation, fixed filter element filter, etc., can solve the problems of time-consuming and labor-intensive product output, difficulty in installing rubber strips, and increased production costs, etc., to achieve Reduce labor intensity, avoid corrosion of cloth pressing grooves, and increase productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

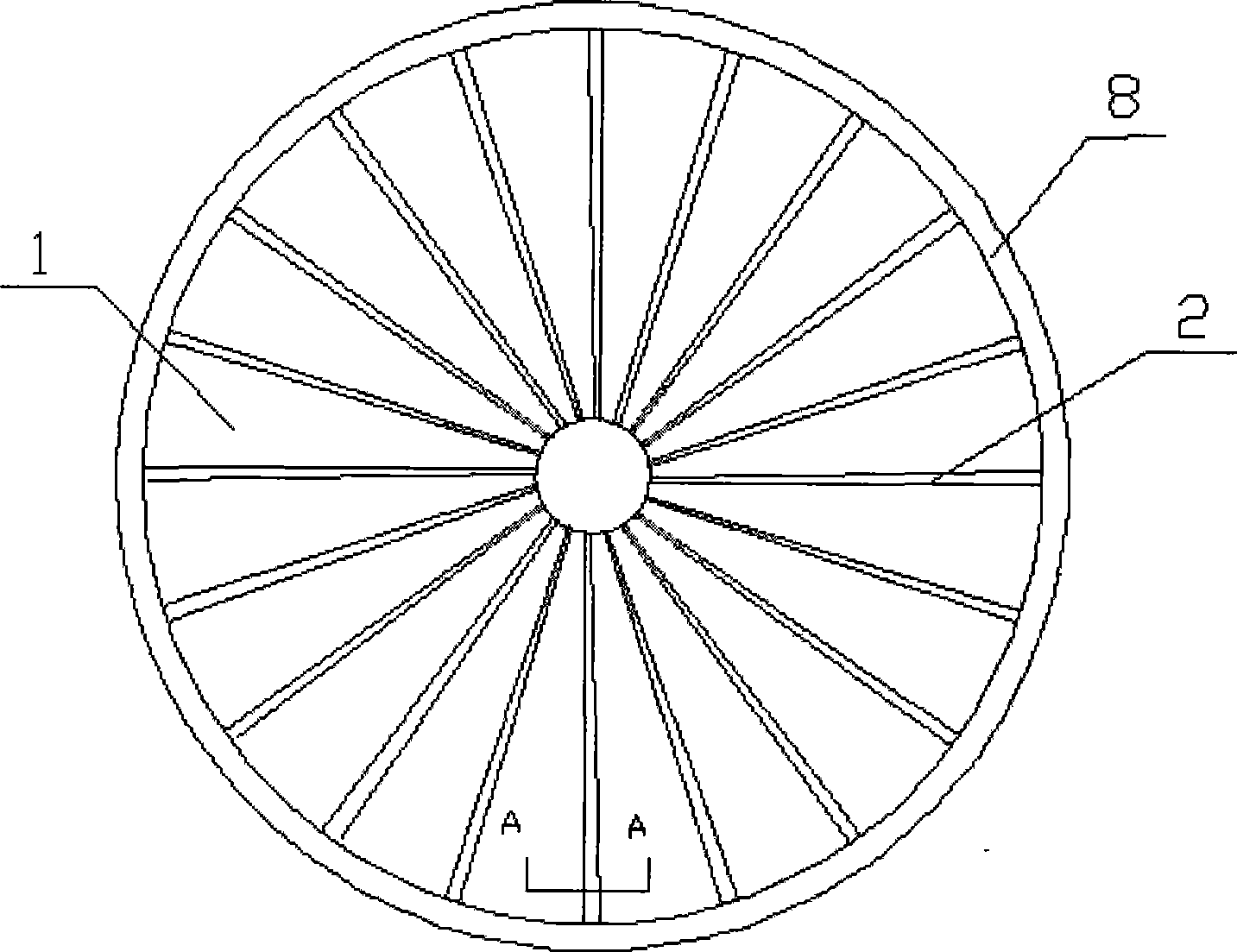

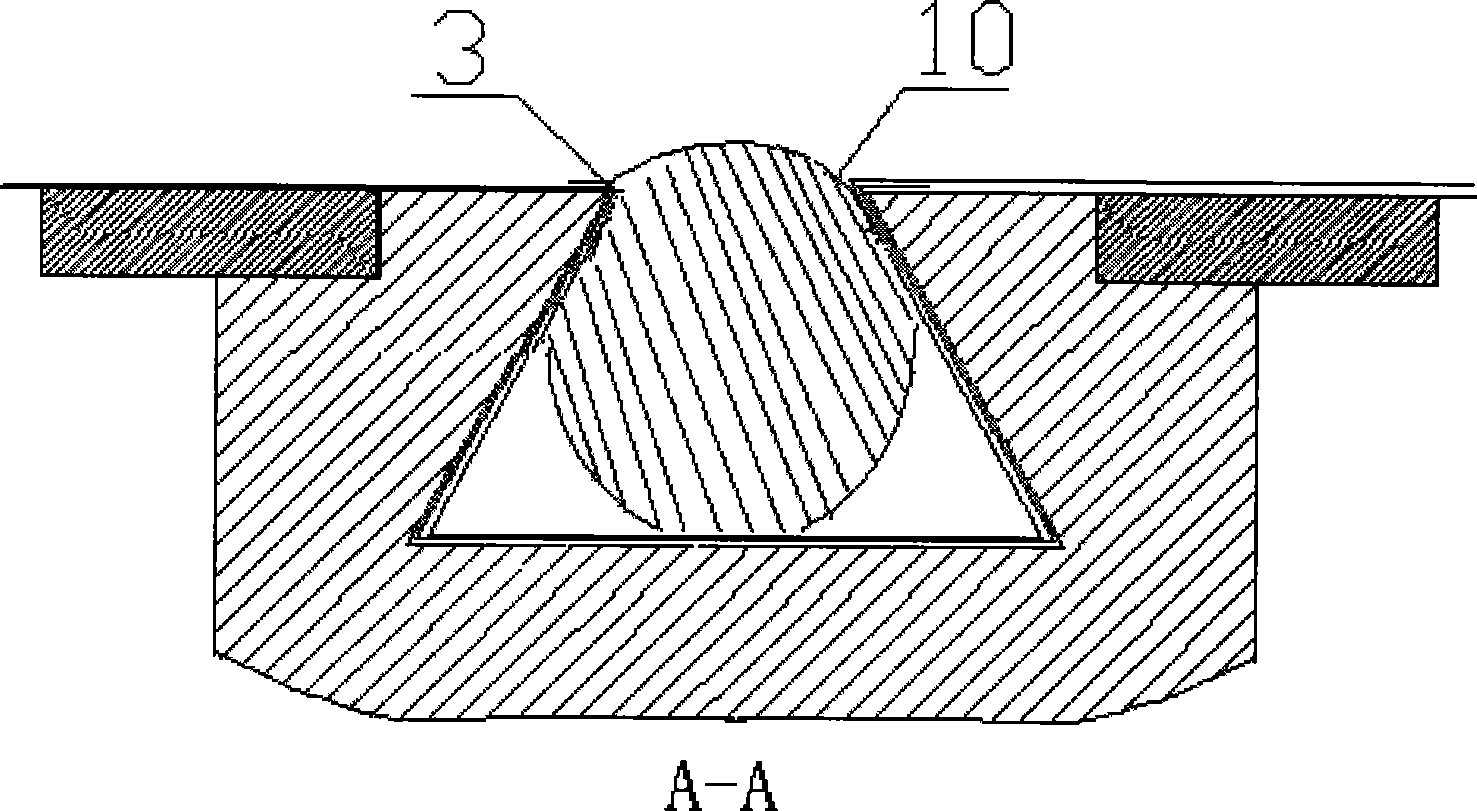

[0029] Embodiment: The present invention includes a filter plate surface 1, a linear cloth pressing groove 2, a circular cloth pressing groove 8, a filter cloth 3, a trapezoidal pressing groove 4, a bottom pressing bar 5 and a screw 6. There is a filter cloth 3 on the filter plate 1, the joint of the filter cloth 3 is located in the groove of the linear cloth pressing groove 2, the bottom bead 5 is pressed on the joint of the filter cloth 3, and the bottom bead 5 is a trapezoidal pressing groove 4, and the trapezoidal pressing Groove 4 is connected with bottom bead 5 with screw 6 .

[0030]The synthetic plastic polyvinyl chloride with high temperature resistance, strong alkali resistance and certain flexibility is selected, and the trapezoidal pressure groove 4 is obtained through mold opening and injection. The height of the trapezoidal indentation is 12 mm, and the width of the two outer walls is 12 mm. The widest part (the uppermost end of the side wall) of the left and rig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com